I-TPWG315 380 I-DIGITAL PRESSURE Gauge

Kafushane

Kanye nempahla ye-PE impahla eqhubekayo yokupheleliswa nokukhuliswa, ipayipi le-PE lisetshenziswa kakhulu ekunikezeni igesi namanzi, ukulahlwa kwendle, imboni yamakhemikhali, imayini njalonjalo.

Ifektri yethu ibicwaninga futhi yakha umshini we-TPW owuchungechunge wamapayipi we-butt fusion olungele i-PE, PP, ne-PVDF ngaphezu kweminyaka eyishumi.

Namuhla, imikhiqizo yethu ihlanganisa izinhlobo eziyisishiyagalombili nezinhlobo ezingaphezu kwezingu-20 ezisebenza ekwakhiweni kwamapayipi epulasitiki nokwenza ukufakwa ku-workshop ngale ndlela elandelayo:

| SHS uchungechunge isokhethi welder | TPWC uchungechunge Band saw |

| Umshini wokuhlanganisa izinqe ze-TPW uchungechunge | TPWG uchungechunge workshop Welding umshini |

| TPWY uchungechunge butt fusion umshini | Series amathuluzi akhethekile |

| QZD uchungechunge Auto-butt Fusion machine | Umshini wokuhlanganisa isihlalo sehhashi le-SHM |

Leli bhukwana elomshini wokushisela we-TPWG315 wamapayipi epulasitiki. Ukuze ugweme noma yiluphi uhlobo lwengozi ebangelwa ugesi noma umshini. Kunconywa ukuthi ufunde ngokucophelela futhi ulandele imithetho yokuphepha elandelayo ngaphambi kokusebenzisa umshini.

Incazelo ekhethekile

Ngaphambi kokusebenzisa umshini, noma ubani kufanele afunde le ncazelo ngokucophelela futhi ayigcine kahle ukuze aqinisekise ukuphepha kwesisetshenziswa nesisebenzisi, kanye nokuphepha kwabanye.

2.1 Umshini usetshenziselwa ukushisela amapayipi enziwe nge-PE, PP, PVDF futhi awukwazi ukusetshenziselwa ukushisela izinto ngaphandle kwencazelo, ngaphandle kwalokho umshini ungase ulimale noma kwenzeke ingozi ethile.

2.2 Ungawusebenzisi umshini endaweni enengozi yokuqhuma

2.3 Umshini kufanele usebenze ngabasebenzi abanomthwalo wemfanelo, abaqeqeshiwe nabaqeqeshiwe.

2.4 Umshini kufanele usebenze endaweni eyomile. Izinyathelo zokuzivikela kufanele zithathwe uma isetshenziswa emvuleni noma emhlabathini omanzi.

2.5 Umshini wawudinga u-380V±10%, ukunikezwa kwamandla okungu-50 Hz. Uma kufanele kusetshenziswe ikhebula lokunweba, kufanele kube nesigaba esanele ngokuya ngobude bazo.

Ukuphepha

3.1 amamaki okuphepha

Amamaki alandelayo afakwe emshinini:

3.2 Izinyathelo Zokuphepha

Qaphela lapho usebenzisa futhi uhambisa umshini ngokuvumelana nayo yonke imithetho yokuphepha kulo myalelo.

3.2.1 Qaphela uma usebenzisa

l Umsebenzisi kufanele abe ngabasebenzi abaqotho nabaqeqeshiwe.

l Hlola ngokuphelele futhi unakekele umshini ngonyaka ukuze uthole ukuphepha kanye nemishini

ukwethembeka.

3.2.2Amandla

Ibhokisi lokusatshalaliswa kukagesi kufanele libe nesiphazamisi esinephutha eliphansi elinezinga elifanele lokuphepha kukagesi. Wonke amadivaysi okuvikela ukuphepha aboniswa ngamagama aqondakala kalula noma amamaki.

3.2.3 Vala ugesi ngaphambi kokukhipha ikhava yokuphepha noma inethi.

Ukuxhunywa komshini emandleni

Umshini wokuxhuma ikhebula emandleni kufanele ube yi-mechanical concussion kanye nobufakazi bokugqwala kwamakhemikhali. Uma ucingo olunwetshiwe lusetshenziswa, kufanele lube nesigaba sokuhola esanele ngokuya ngobude baso.

Earthing: Yonke isayithi kufanele yabelane ngocingo oluphansi olufanayo futhi uhlelo lokuxhuma phansi kufanele luqedwe futhi luhlolwe abantu abangochwepheshe.

3.2.3Ukugcinwa kwezinto zikagesi

Okwemizuzu. ezingozini, zonke izinto ezisetshenziswayo kumele zisetshenziswe futhi zigcinwe ngendlela elandelayo:

※ Gwema ukusebenzisa izintambo zesikhashana ezingathobeli okujwayelekile

※ Ungathinti izingxenye ze-electrophorus

※ Vimbela ukukhipha ikhebula ukuze unqamule

※ Vimbela izintambo zokudonsa zokuphakamisa imishini

※ Ungabeki into esindayo noma ecijile ezintanjeni, futhi ulawule izinga lokushisa lekhebula phakathi kwezinga lokushisa elilinganiselwe (70℃)

※ Ungasebenzi endaweni emanzi. Hlola ukuthi i-groove nezicathulo zomile yini.

※ Ungachaphazi umshini

3.2.4 Hlola isimo sokushisa somshini ngezikhathi ezithile

※ Hlola ukwahlukanisa kwezintambo ikakhulukazi amaphuzu akhishiwe

※ Ungawusebenzisi umshini ngaphansi kwesimo esibucayi.

※ Hlola ukuthi ukushintsha ukuvuza kusebenza kahle yini okungenani ngesonto.

※ Hlola umhlaba womshini ngabasebenzi abaqeqeshiwe

3.2.5 Hlanza futhi uhlole umshini ngokucophelela

※ Ungasebenzisi izinto ezisetshenziswayo (ezifana ne-abrasive, nezinye izincibilikisi) ezilimaza ukufakwa kalula lapho uhlanza umshini.

※ Qiniseka ukuthi amandla anqanyuliwe lapho uqeda umsebenzi.

※ Qiniseka ukuthi akukho monakalo emshinini ngaphambi kokuphinda usebenzise.

Uma kuphela ukulandela okushiwo ngenhla, ukuqapha kungasebenza kahle.

3.2.6 Iyaqala

Qiniseka ukuthi iswishi yomshini ivaliwe ngaphambi kokuyivula.

3.2.7 Ukuqina kwezingxenye

Qinisekisa ukuthi amapayipi alungiswe kahle. Qinisekisa ukuthi ingakwazi ukuhamba kahle futhi uyivimbele ukuthi ingasheleli phansi.

3.2.8 Indawo yokusebenza

Gwema ukusebenzisa umshini endaweni egcwele upende, igesi, intuthu kanye ne-deoil, ngoba ukutheleleka kwamehlo nemigudu yokuphefumula kungabangelwa.

Ungawubeki umshini endaweni engcolile.

3.2.9 Ukuphepha kwabasebenzi ngenkathi besebenza

Susa ubucwebe namaringi, futhi ayigqoki izingubo ezixegayo gwema ukugqoka ileyisi yezicathulo, amadevu amade noma izinwele ezinde ezingase ziboshwe emshinini.

3.3 Ukuphepha Kwezisetshenziswa

Umshini wokushisela we-Hydraulic workshop welding usebenza kuphela uchwepheshe noma isisebenzi esinesitifiketi esiqeqeshiwe. Umuntu ovamile angalimaza umshini noma abanye abaseduze.

3.3.1 Ipuleti lokushisisa

l Izinga lokushisa elingaphezulu lepuleti lokushisisa lingafinyelela ku-270℃.Ungalokothi ulithinte ngokuqondile ukuze ugweme ukusha

l Ngaphambi nangemva kokusebenzisa, hlanza indawo ngendwangu ethambile. Gwema izinto ezihuquzelayo ezingase zilimaze ukunamathela.

l Hlola ikhebula lepuleti lokushisisa futhi uqinisekise izinga lokushisa elingaphezulu.

3.3.2 Ithuluzi lokuhlela

l Ngaphambi kokushefa amapayipi, iziphetho zamapayipi kufanele zihlanzwe, ikakhulukazi ukuhlanza isihlabathi noma enye idrafu ekhala emaphethelweni. Ngokwenza lokhu, ukuphila onqenqemeni kungenziwa isikhathi eside, futhi kuvimbele ukuthi ama-shavings aphonswe ngaphandle kubantu abayingozi.

l Qinisekisa ukuthi ithuluzi lokuhlela livalwe ngokuqinile emaphethelweni amabili wamapayipi

3.3.3 Uhlaka oluyinhloko:

l Qinisekisa ukuthi amapayipi noma izixhumi zifakwe ngendlela efanele ukuze ziqondane kahle.

l Lapho uhlanganisa amapayipi, u-opharetha kufanele agcine indawo ethile emshinini ukuze kuphephe abasebenzi.

l Ngaphambi kokuthutha, qiniseka ukuthi zonke izinsimbi zilungiswe kahle futhi azikwazi ukuwa ngesikhathi sokuthutha.

I-Range Esebenzayo Nezinhlaka Zobuchwepheshe

| Uhlobo | I-TPWG315 | |

| Izinto zokushisela | I-PE, PP, i-PVDF | |

| Ngaphandle Ububanzi ububanzi | indololwane (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm |

| i-tee (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| isiphambano (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| I-Wyes 45°&60° (DN,mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Izinga lokushisa kwemvelo | ℃ 5 ~ 45℃ | |

| Amafutha e-hydraulic | 40 - 50 (i-kinematic viscosity) mm2/s, 40℃) | |

| Ukunikezwa kwamandla kagesi | ~380 V±10% | |

| Imvamisa | 50 Hz | |

| Isamba samanje | 13 A | |

| Amandla aphelele | 7.4 KW | |

| Faka, ipuleti lokushisa | 5.15 KW | |

| Ithuluzi lokuhlela injini | 1.5 kW | |

| I-Hydraulic unit motor | 0.75 kW | |

| Ukumelana ne-insulating | >1MΩ | |

| Ubukhulu. umfutho we-hydraulic | 6 MPa | |

| Ingxenye ephelele yamasilinda | 12.56 cm2 | |

| Ubukhulu. izinga lokushisa lokushisa ipuleti | 270℃ | |

| Umehluko ekushiseni okungaphezulu kwepuleti lokushisa | ± 7℃ | |

| Umsindo ongafunwa | <70 dB | |

| Ithangi lamafutha Umthamo | 55L | |

| Isisindo esiphelele(kg) | 995 | |

Izincazelo

Umshini wokushisela we-workshop ungakhiqiza indololwane, i-tee, ukuwela ngepayipi le-PE endaweni yokusebenzela. Izinsimbi ezijwayelekile zihambisana nosayizi bamapayipi abajwayelekile ngokuya nge-ISO161/1.

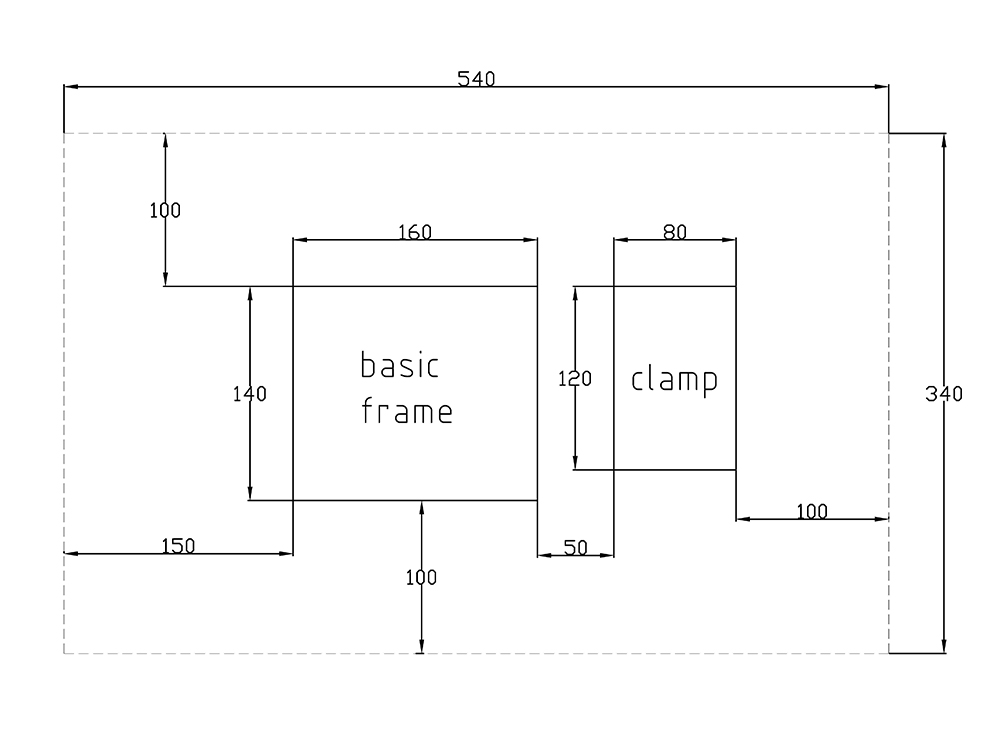

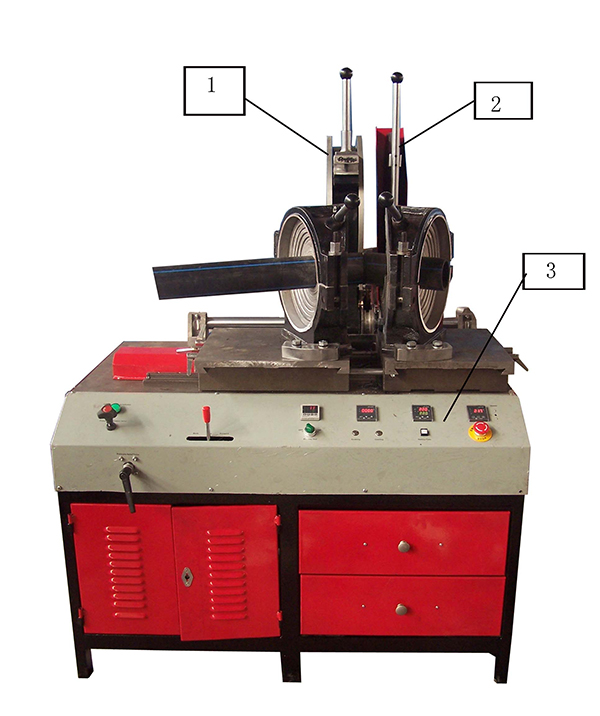

5.1 Umshini omkhulu

| 1. Ithuluzi lokuhlela | 2. Ipuleti lokushisa | 3. Iphaneli yokusebenza |

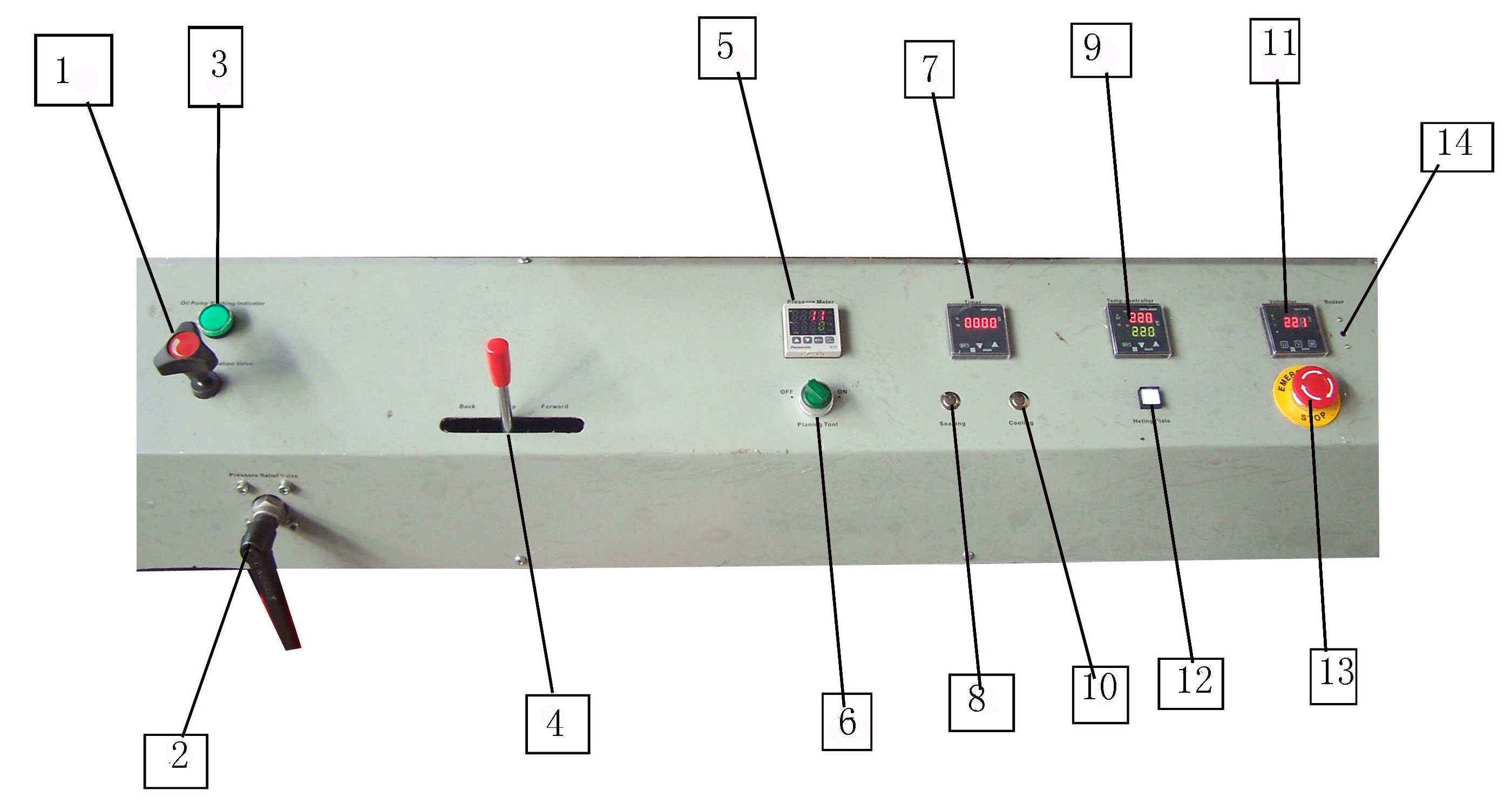

5.2 Iphaneli yokusebenza

| 1. I-Valve Yokulawula Ingcindezi | 2. I-Valve Yokusiza Ukucindezela | 3. I-Oil Pump Working Inkomba | 4. I-Direction Valve |

| 5. Digital Pressure Meter | 6. Inkinobho yokuhlela | 7. Isibali sikhathi | 8. Inkinobho Yesikhathi Sokucwiliswa |

| 9. Imitha yokulawula izinga lokushisa | 10. Inkinobho Yesikhathi Sokupholisa | 11. I-Voltmeter | 12. I-Heating Switch |

| 13. I-Emergency Stop | 14. Umabhebhana |

Ukufakwa

6.1 Ukuphakamisa nokufakwa

Lapho uphakamisa futhi ufaka umshini kufanele ugcinwe uvundlile, futhi ungalokothi uwuhlehlise noma uwuhlehlise ukuze ugweme umonakalo ongafuneki.

6.1.1 Uma kusetshenziswa i-forklift, kufanele ifakwe ngokucophelela kusukela phansi komshini ngokucophelela ukuze kugwenywe ukulimaza ipayipi likawoyela kanye nesekhethi.

6.1.2 Uma uhambisa umshini endaweni yokuwufaka, uhlaka oluyinhloko kufanele lugcinwe luzinzile futhi luvundlile.

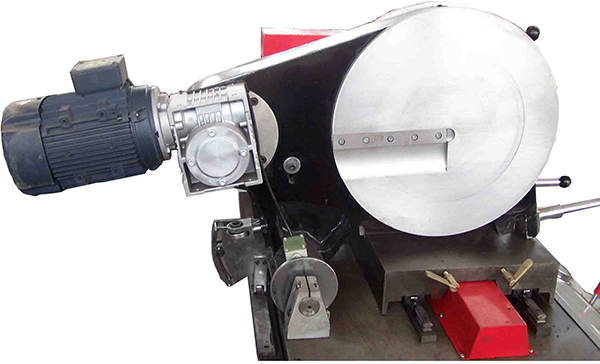

6.1.3 Faka injini ebhokisini lokunciphisa lethuluzi lokuhlela futhi lilungiswe ngezikulufu, eziboniswe ku-Fig .3.

6.2 Ukuxhumana

Qinisekisa ukuthi isikhala sanele ukubeka umshini futhi ugcine wonke umshini uvundlile futhi uqinisekise ukuxhumana okulungile kwawo wonke amasokhethi, izintambo namapayipi lapho ufaka umshini.

6.2.1 Xhuma umshini omkhulu ebhokisini likagesi.

Umfanekiso 4 Xhuma ipuleti lokushisisa ebhokisini likagesi

Umfanekiso 5 Xhuma ithuluzi lokuhlela ebhokisini likagesi

6.2.2 Ukuxhuma ikhebula lomshini emandleni, okuyizigaba ezintathu- izintambo ezinhlanu 380V 50HZ.

Ukuze uphephe, umshini kufanele ufakwe emhlabathini kusukela endaweni ephansi yomshini.

6.2.3 Gcwalisa uwoyela we-hydraulic ohlungiwe. Ubude bamafutha kufanele bube ngaphezu kuka-2/3 wobude bobubanzi begeji yokuqukethwe.

Isexwayiso: Ukwenza umhlaba kufanele kuqedwe ngabantu abangochwepheshe.

Umyalelo Wokusetshenziswa

Landela yonke imithetho yokuphepha emshinini. Umuntu ongaqeqeshiwe akavunyelwe ukusebenzisa umshini.

7.1 Amandla

Vala isiphazamisi sephutha eliphansi

7.2 Qala iphampu kawoyela

Qala iphampu yamafutha ukuze ubuke isiqondiso esijikelezayo. Uma igeji yokucindezela inokufundwa, ukujikeleza kulungile, uma kungenjalo, shintshanisa noma yiziphi izintambo ezimbili ezibukhoma.

7.3 Hlola futhi ulungise ingcindezi yokudonsa futhi unyakazise isivinini sepuleti lokudonsa. Ingcindezi yokusebenza yesistimu ingu-6 MPa. Ukucindezela okuhlanganisayo kungalungiswa nge-valve yokulawula ingcindezi etholakala kuphaneli yokulawula. Ingcindezi yokuhlela kufanele inyuswe kancane kancane, futhi igcine lapho kuvela ama-shavings aqhubekayo (hhayi kakhulu). Ijubane lokuphakelayo lepuleti lokuhudula lingashintshwa nge-valve yokuhlola (ngaphakathi kwesisekelo).

7.4 Ukufakwa kwama-clamps

Faka izihlalo zokunamathisela kwesokunxele nesokudla (izinsimbi zama tee noma izindololwane) ngokuya ngezinto okumele zenziwe.

1) Zilungise kuqala ngephini lokukhiya elixhunywe nomshini;

2) Lungisa i-engeli ngesibambo sendawo ekhethekile;

3) Qinisa isikulufu sokukhiya ngesikrufu.

Uma izinsimbi zendololwane zidinga ukusetshenziswa, zicindezele ngokuqinile ngepuleti lokukhiya ngemva kokulungisa i-engeli.

7.5 Setha izinga lokushisa elicacisiwe kwisilawuli sokushisa ngokuya ngenqubo yokushisela ipayipi. (Bheka isigaba 7.10)

7.6 Ngaphambi kokuphakamisa noma ukwehlisa ithuluzi lokuhlela vula idivayisi yokukhiya esibambeni.

7.7 Amapayipi ami emshinini

7.7.1 Hlukanisa izinsimbi zomshini ngokusebenza ku-lever yevalvu eqondisayo

7.7.2 Faka amapayipi kuma-clamps futhi uwabophe; isikhala phakathi kweziphetho ezimbili zamapayipi kufanele sanele ithuluzi lokuhlela.

7.7.3 Ivalvu yokukhulula ukucindezela kokukhiya, ngenkathi uvala iziphetho ezimbili, vula i-valve yokulawula ingcindezi kuze kube yilapho igeji yokucindezela ikhombisa ukucindezela kokuhlangana, okunqunywa izinto zamapayipi.

7.8 Ukuhlela

7.8.1 Hlukanisa ama-clamps ngokusebenza ku-valve eqondisayo kanye ne-valve yokukhulula ukucindezela evuleke ngokugcwele.

7.8.2 Beka ithuluzi lokuhlela phakathi kwamaphethelo amabili wamapayipi bese uvula, sondela emaphethelweni epayipi ngasethuluzini lokuhlela ngokusebenza ngevalvu eqondisayo “phambili”, bese ulungisa ivalve elawula umfutho ukuze igcine umfutho ofanele kuze kuvele ukushefa okuqhubekayo kumabili. izinhlangothi.Qaphela: 1) Ubukhulu bokushefa kufanele bube phakathi kuka-0.2 ~ 0.5mm futhi bungashintshwa ngokulungisa ukuphakama kwethuluzi lokuhlela.

I-2) Ingcindezi yokuhlela akufanele idlule i-2.0 MPa ukugwema ukulimala kwethuluzi lokuhlela.

7.8.3 Ngemva kokuhlela, Hlukanisa izinsimbi bese ukhipha ithuluzi lokuhlela.

7.8.4 Vala iziphetho ezimbili ukuze uziqondanise. Uma ukungahambi kahle kudlula i-10% yobukhulu bepayipi, yithuthukise ngokukhulula noma ukuqinisa izinsimbi ezingaphezulu. Uma igebe phakathi kweziphetho lingaphezu kuka-10% wogqinsi lwepayipi, phinda uhlele ipayipi uze uthole imfuneko.

7.9 Ukushisela

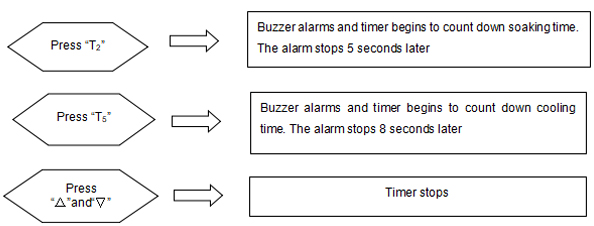

7.9.1 Setha isikhathi sokucwiliswa kanye nesikhathi sokupholisa ngokwenqubo yokushisela.

7.9.2 Ngemva kokukhipha ithuluzi lokuhlela, beka ipuleti lokushisisa, Khiya i-valve yokukhulula ingcindezi kancane kancane ngenkathi uphushela i-valve eya phambili, okwandisa ukucindezela kokushisisa kumfutho we-fusion oshiwo.1). Ipayipi ligcina linamathela epuleti lokushisisa futhi ukuhlanganisa kuyaqala.

7.9.3 Uma ubuhlalu obuncane bukhula, buyisela emuva ivalvu eqondisayo phakathi nendawo ukuze ugcine umfutho. Vula i-valve yokuhlola i-swing ukuze wehlise ingcindezi yokucwiliswa emanzini (P2) bese uyikhiya ngokushesha. Bese ucindezela phansi inkinobho yesikhathi sokucwiliswa kusikhathi.

7.9.4 Ngemva kokucwiliswa emanzini (ama-alamu e-buzzer), vula izinsimbi ngokusebenza ku-valve eqondisayo bese ususa ipuleti lokushisa ngokushesha.

7.9.5 Joyina iziphetho ezimbili ezincibilikisiwe ngokushesha futhi ugcine i-valve eqondisayo “phambili” isikhathi esifushane bese uhlehlela emuva endaweni ephakathi nendawo ukuze ugcine ukucindezela. Ngalesi sikhathi, ukufundwa kwegeji yokucindezela isethi yokucindezela kwe-fusion (uma kungenjalo, yilungise ngokusebenza ku-valve yokulawula ingcindezi).

7.9.6 Cindezela phansi inkinobho yesikhathi sokupholisa uma ukupholisa kuqala. Ngemuva kokuthi isikhathi sokupholisa sesidlulile, i-buzzer iyakhala. Phinda uphile ukucindezela kwesistimu ngokusebenza ku-valve yokukhulula ingcindezi, vula izinsimbi futhi ukhiphe amalunga.

7.9.7 Hlola ijoyinti ngokwamazinga enqubo yokushisela.

7.10 Isilawuli sezinga lokushisa nesibali sikhathi

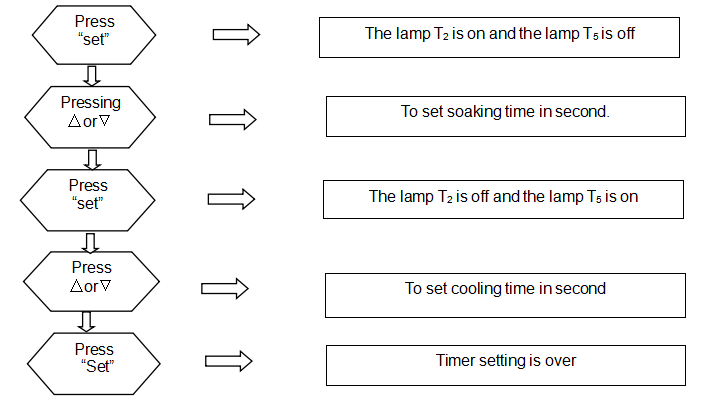

7.10.1 Ukusetha isikhathi

7.10 Isilawuli sezinga lokushisa nesibali sikhathi

7.10.1 Ukusetha isikhathi

7.10.2 Ukusebenzisa isikhathi

7.10.3 Ukulungiselelwa kwesilawuli sezinga lokushisa

1) Cindezela okuthi “SET” imizuzwana engaphezu kwemi-3 kuze kuvele u-“sd” efasiteleni eliphezulu

2) Cindezela okuthi “∧” noma “∨” ukuze uguqule inani libe kuzinga lokushisa elishiwo (cindezela “∧” noma “∨” ngokuqhubekayo, inani lizohlanganisa noma lisuse ngokuzenzakalelayo)

3) Ngemva kokusetha, cindezela u-“SET” ukuze ubuyele ekuqapheni nasekulawuleni isixhumi esibonakalayo

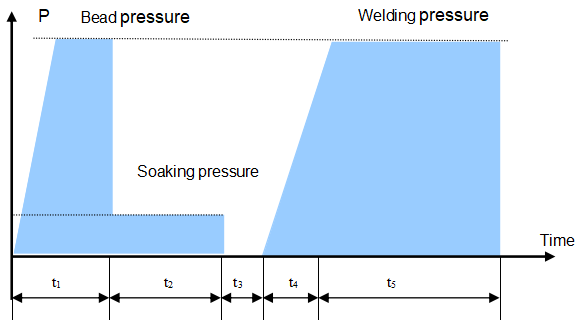

I-Reference Welding Standard (DVS2207-1-1995)

I-8.1 Ngenxa yamazinga ahlukene we-welding kanye nezinto ze-PE, isikhathi nokucindezela kwesigaba senqubo yokuhlanganisa kuhlukile. Iphakamisa ukuthi amapharamitha wokushisela wangempela kufanele afakazelwe ngamapayipi nezinto ezifakwayo

8.2 Uma kunikezwe izinga lokushisa lokushisela lamapayipi enziwe nge-PE, PP kanye ne-PVDF nge-DVS amabanga ajwayelekile ukusuka ku-180 ℃ kuya ku-270 ℃. Ukushisa kwesicelo sepuleti lokushisa kungaphakathi kwe-180℃230℃, kanye ne-Max yayo. izinga lokushisa kwamanzi lingafinyelela ku-270 ℃.

8.3 Izinga lokubhekiselaI-DVS2207-1-1995

| Ukujiya kodonga (mm) | Ubude be-bead (mm) | Ingcindezi yokwakha ubuhlalu (MPa) | Isikhathi sokucwilisa t2(Isekhondi) | Ukucwiliswa kwengcindezi (MPa) | Ukushintsha kwesikhathi t3(umzuzwana) | Isikhathi sokwakha ingcindezi t4(umzuzwana) | Ingcindezi yokushisela (MPa) | Isikhathi sokupholisa t5(imizuzu) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45; 70 | ≤0.02 | 5; 6 | 5; 6 | 0.15±0.01 | 6; 10 |

| 7; 12 | 1.5 | 0.15 | 70 - 120 | ≤0.02 | 6; 8 | 6; 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8; 10 | 8; 11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26; 37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32; 45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45; 60 |

| 50-70 | 4.0 | 0.15 | 500-700 | ≤0.02 | 20 - 25 | 25-35 | 0.15±0.01 | 60-80 |

Phawula:Ingcindezi yokwakha ubuhlalu kanye nengcindezi yokushisela efomini ingcindezi yesibonisi esinconyiwe, ingcindezi yegeji kufanele ibalwe ngefomula elandelayo.

Inqubo yokufaka i-Fabricating

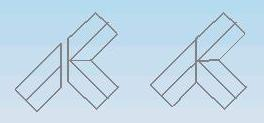

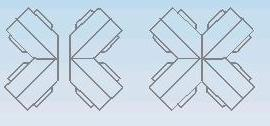

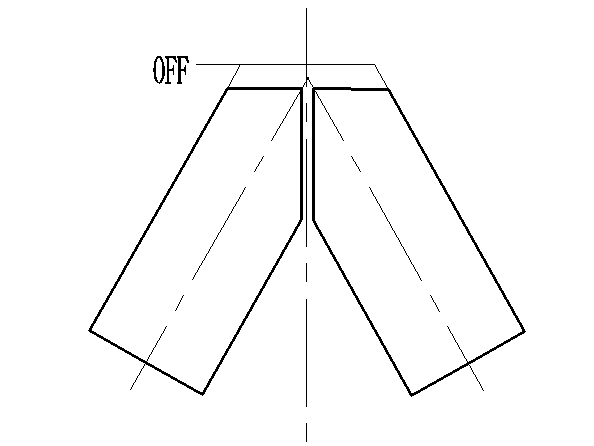

9.1 Ukwenza indololwane

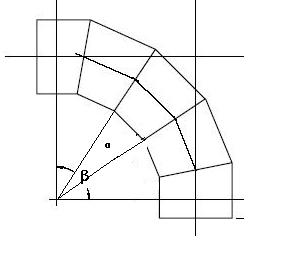

9.1.1 Ngokwe-engeli yendololwane kanye nenani lezingxenye zokushisela, i-engeli yokushisela phakathi kwazo zonke izingxenye kunganqunywa.

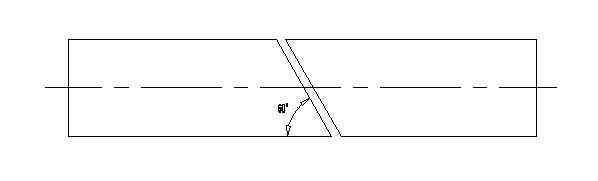

Incazelo: α - i-engeli yokushisela

β - i-elbow angle

n - ubuningi bamasegimenti

Isibonelo: indololwane engu-90 ihlukaniswe yaba izingxenye ezinhlanu ezizoshiselwa, i-engeli yokushisela α=β/(n-1)=90°/(5-1)=22.5°

9.1.2 I-min dimension yayo yonke ingxenye yokushisela enanini lezingxenye zokushisela isikwa ngesaha ngokwe-engeli.

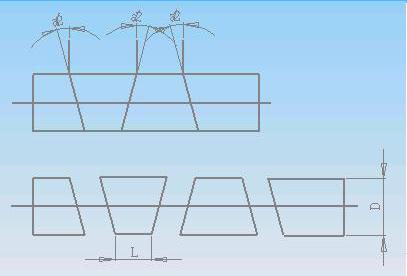

Incazelo:

D - ububanzi obungaphandle bepayipi

L - Ubude obuncane bazo zonke izingxenye

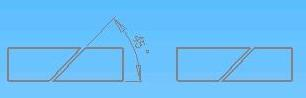

9.2 Inqubo yokukhiqiza amantombazane

9.2.1 Izinto ezisetshenziswayo zinjengomdwebo olandelayo:

9.2.2 Ukushisela njengesakhiwo somdwebo:

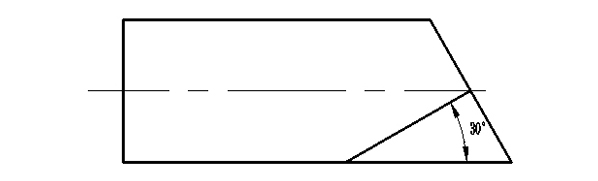

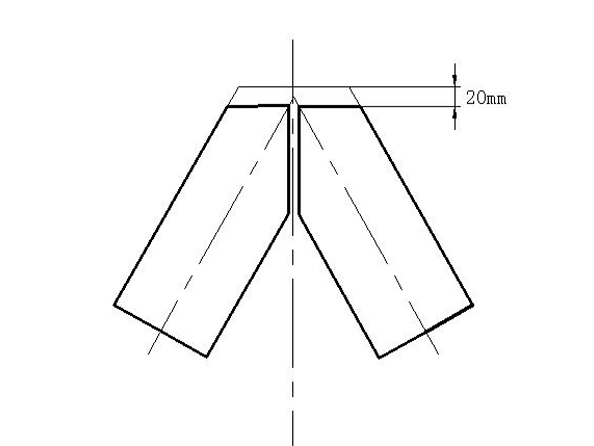

9.2.3 I-engeli iyasikwa njengomdwebo

Isaziso: Ubukhulu “a” akumele bube ngaphansi kuka-20㎜okufana nemajini yokuhlela kanye nokunxephezela ngobuhlalu obuncibilikayo.

9.2.4 Ukushisela njengesakhiwo somdwebo, ama-tee asekhiqiziwe.

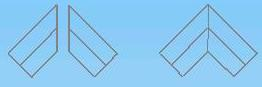

9.3 Inqubo yamapayipi awela ububanzi obulinganayo enziwe

9.3.1 Izinto ezisetshenziswayo zisikwa njengomdwebo olandelayo

9.3.2 Ama-couplers amabili ashiselwe njengesakhiwo somdwebo:

9.3.3 I-engeli isikwa njengomdwebo:

Isaziso: Ubukhulu “a” akumele bube ngaphansi kuka-20㎜,Okuhlelela imajini futhi kunxeshezelwe ngobuhlalu obuncibilikayo.

9.3.4 Ishiselwe njengesakhiwo somdwebo.

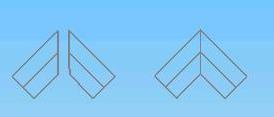

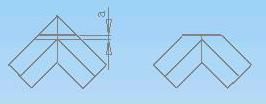

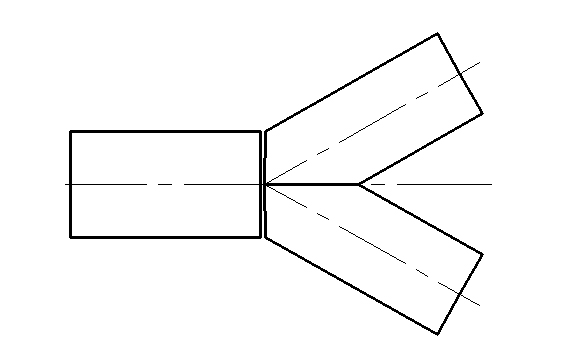

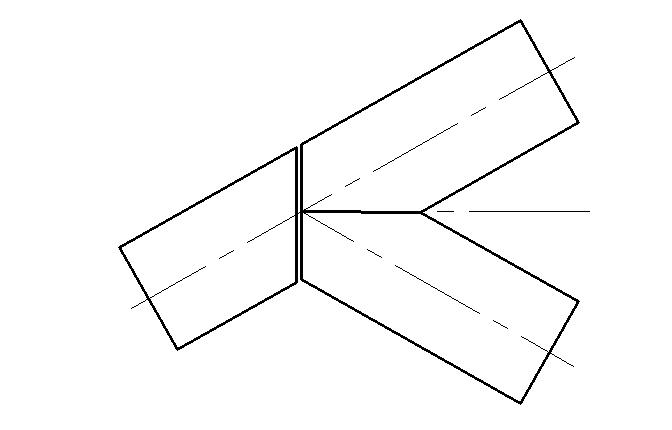

9.4 Inqubo yokwenziwa kokufakwa komumo “Y” (45° noma 60°)

9.4.1 sika njengomdwebo olandelayo (thatha u-60°“Y” ukufakwa komumo njengesibonelo)

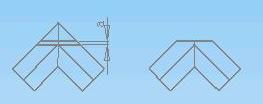

9.4.2 Qhubekela ekushiseleni kokuqala njengemidwebo elandelayo:

9.4.3 Lungisa izinsimbi bese uqhubekela ekushiseleni okwesibili.

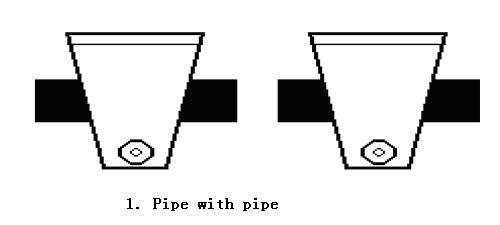

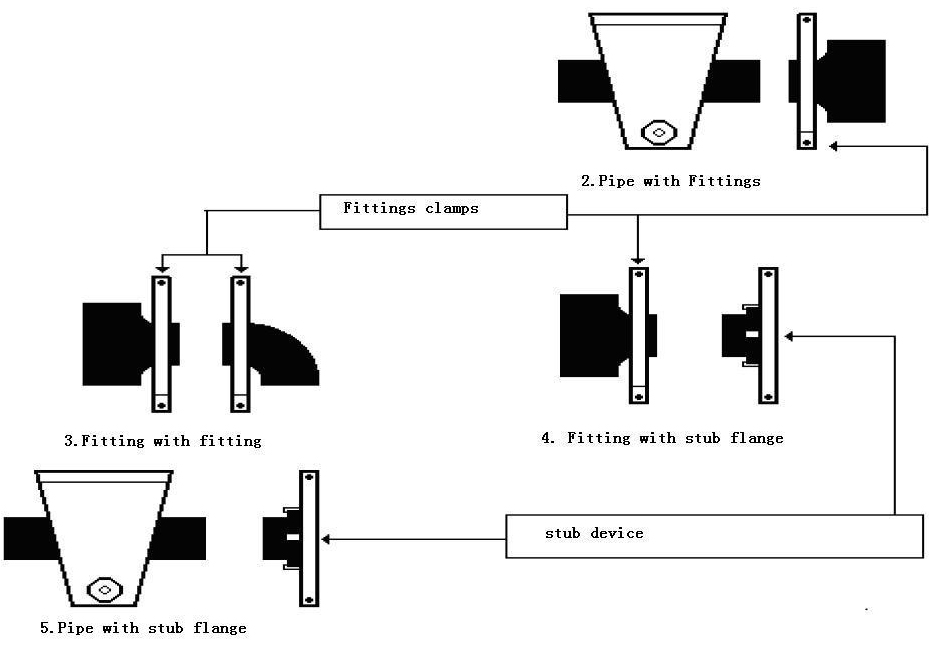

9.5 ezinye izinto zokushisela

9.5.1. Ipayipi ngepayipi

9.5.2. Ipayipi ngokufaka

9.5.3 Ukufakwa ngokufaka

9.5.4 Ukufakwa nge-stub flange

9.5.5 Ipayipi eline-stub flange

Ukuhlaziya Izinkinga Nezixazululo

10.1 Izinkinga zekhwalithi zamalunga ezivamile zihlaziya:

10.2 Isondlo

u PTFE camera bafudumale plate

Sicela uqikelele ukuphatha isibuko sokushisisa ukuze ugweme ukulimala kwe-PTFE.

Gcina njalo uhlanza izindawo ezimboziwe ze-PTFE, ukuhlanzwa kufanele kwenziwe ngobuso obusafudumele ngokusebenzisa indwangu ethambile noma iphepha, ukugwema izinto ezilimazayo ezingase zilimaze izindawo ezimboziwe ze-PTFE.

Ngezikhathi ezithile, siphakamisa ukuthi:

- Hlanza izindawo ezingaphezulu usebenzisa okokugeza okuhwamukayo okusheshayo (utshwala)

- Hlola ukuqiniswa kwezikulufu kanye nekhebula nesimo sepulaki

u Ithuluzi lokuhlela

Kunconywa kakhulu ukuthi uhlale uhlanzekile izindwani futhi ugeze ama-pulley ngokusebenzisa okokuhlanza.

Ngezikhathi ezijwayelekile yenza umsebenzi wokuhlanza ophelele nge-lubrication yangaphakathi futhi

iyunithi ye-Hydraulic

Iyunithi ye-hydraulic ayidingi ukulungiswa okuthile nokho kufanele kulandelwe imiyalo elandelayo:

a. Hlola ngezikhathi ezithile uwoyela ovundlile futhi uma kwenzeka wengeza ngohlobo lwamafutha:

Okuvundlile akufanele kube ngaphansi kuka-5 cm ukusuka ethangini elivundlile.

Ukuhlola njalo ezinsukwini zokusebenza eziyi-15 kuphakanyiswa kakhulu.

b. Shintsha uwoyela ngokuphelele njalo ezinyangeni eziyisi-6 noma ngemva kwamahora okusebenza angama-630.

c. Gcina iyunithi ye-hydraulic ihlanzekile ngokunakekela okukhethekile ethangini kanye nama-couplings asheshayo.

10.3 Ukuhlaziya ukungasebenzi kahle kanye nesixazululo

Ngesikhathi sokusebenzisa, iyunithi ye-hydraulic kanye namayunithi kagesi kungase kubonakale izinkinga ezithile. Ukungasebenzi kahle okuvamile kubalwe kanje:

Sicela usebenzise amathuluzi anamathiselwe, izingxenye ezisele noma amanye amathuluzi anesitifiketi sokuphepha ngenkathi unakekela noma ushintsha izingxenye. Amathuluzi nezingxenye ezisele ngaphandle kwesitifiketi sokuphepha kwenqatshelwe ukusetshenziswa.

| Ukungasebenzi kahle kweyunithi ye-hydraulic | |||||

| No | ukungasebenzi kahle | uyahlaziya | izixazululo | ||

| 1 | Injini ayisebenzi |

ikhululiwe

| |||

| 2 | Injini iphenduka kancane kakhulu ngomsindo ongajwayelekile |

| ngaphezu kwe-3 MPa

| ||

| 3 | Isilinda sisebenza ngendlela engavamile |

ikhiywe ngokuqinile

| ukuphuma emoyeni. | ||

| 4 | Isilinda esidonsa ipuleti elinyakazayo akusebenzi |

i-valve ivinjiwe |

i-valve yokuchichima (1.5 MPa ilungile).

| ||

| 5 | Ukuvuza kwesilinda | 1. Indandatho kawoyela inephutha2. Isilinda noma ipiston yonakale kabi | 1. Faka esikhundleni indandatho kawoyela2. Faka esikhundleni isilinda | ||

| 6 | Ingcindezi ayikwazi ukunyuswa noma ukushintshashintsha kukhulu kakhulu | 1. Umnyombo wevalvu yokuchichima uvaliwe.2. Iphampu liyavuza.3. Ukuxega okuhlangene kwephampu kuyaxegiswa noma i-key groove i-skid. | 1. Hlanza noma shintsha i-valve engumongo we-over-flow2. Shintshanisa iphampu kawoyela3. Shintshanisa i-joint slack | ||

| 7 | Ukucindezela kokusika akukwazi ukulungiswa | 1. Isekhethi inephutha2. Ikhoyili ye-electromagnetic inephutha3. I-valve yokuchichima ivinjiwe4. I-valve yokusika echichimayo ayijwayelekile | 1. Hlola isekethe (i-diodein ebomvu ikhoyili kazibuthe iyakhanya)2. Faka esikhundleni ikhoyili kagesi3. Hlanza umnyombo we-valve yokugeleza ngokweqile4. Hlola i-valve yokusika ukugeleza ngokweqile | ||

| Ukungasebenzi kahle kwamayunithi kagesi | |||||

| 8 | Umshini wonke awusebenzi |

| 1. Hlola ikhebula lamandla2. Hlola amandla okusebenza3. Vula isiphazamisi sephutha eliphansi | ||

| 9 | Uhambo lokushintsha iphutha eliphansi |

| 1. Hlola izintambo zikagesi2. Hlola izakhi zikagesi.3. Hlola idivayisi yokuphepha kwamandla ephezulu | ||

| 10 | Izinga lokushisa likhuphuka ngendlela engavamile |

4. 4. Uma ukufundwa kwesilawuli sezinga lokushisa kufanele kube ngaphezu kuka-300℃, okuphakamisa ukuthi inzwa yakhe ingase ilimale noma uxhumo luxege. Uma isilawuli sezinga lokushisa kufanele sibonise i-LL, okuphakamisa ukuthi inzwa ibe nesekhethi emfushane. Uma ngabe isilawuli sezinga lokushisa kufanele sibonise i-HH, okuphakamisa ukuthi ukujikeleza kwenzwa kuvuliwe. 5. Lungisa izinga lokushisa ngenkinobho etholakala kusilawuli sezinga lokushisa.

| abathintwayo

isilawuli

setha izinga lokushisa

oxhumana nabo uma kunesidingo | ||

| 11 | Ukulahlekelwa ukulawula lapho ushisisa | Ukukhanya okubomvu kuyakhanya, kodwa izinga lokushisa lisakhuphuka, lokho kungenxa yokuthi isixhumi sinephutha noma amalunga 7 no-8 awakwazi ukuvula lapho ethola izinga lokushisa elidingekayo. | Faka esikhundleni isilawuli sezinga lokushisa | ||

| 12 | Ithuluzi lokuhlela alizungezi | Ukushintsha okulinganiselwe akusebenzi noma izingxenye zemishini zethuluzi lokuhlela ziyasikwa. | Shintshanisa umkhawulo wethuluzi lokuhlela shintsha noma i-sprocket encane | ||

Umdwebo weSekethe & Hydraulic Unit Diagram

11.1 Umdwebo weyunithi yesifunda (ubonwa kusithasiselo)

11.2 Umdwebo weyunithi yeHydraulic (ubonwa kusithasiselo)

Ishadi Lomsebenzi Wasemkhathini