TPWC315 IBHANDE LOKUSEBENZA KWE-SAW

Incazelo ekhethekile

Ngaphambi kokusebenzisa umshini, noma ubani kufanele afunde le ncazelo ngokucophelela futhi ayigcine kahle ukuze aqinisekise ukuphepha kwesisetshenziswa nesisebenzisi, kanye nokuphepha kwabanye.

2.1 Lo mshini usetshenziselwa ukusika amapayipi enziwe nge-PE, PP kanye ne-PVDF futhi awukwazi ukusetshenziselwa ukusika izinto ezingachazeki; ngaphandle kwalokho umshini ungase ulimale noma ubangele ingozi.

2.2 Ungawusebenzisi umshini endaweni enengozi yokuqhuma

2.3 Umshini kufanele usebenze ngabasebenzi abanomthwalo wemfanelo, abaqeqeshiwe nabaqeqeshiwe.

2.4 Umshini kufanele usebenze endaweni eyomile. Izinyathelo zokuzivikela kufanele zithathwe uma isetshenziswa emvuleni noma emhlabathini omanzi.

2.5 Amandla okokufaka angaphakathi kuka-380V±10%, 50 Hz. Uma kusetshenziswa umugqa wokufaka owandisiwe, ulayini kufanele ube nesigaba sokuhola esanele.

2.6 Gcwalisa uwoyela we-hydraulic (N46 ISO3448) ethangini ngaphambi kokuqala ukusebenzisa. Umthamo kawoyela kufanele ube cishe u-2/3 wethangi.

Ukuphepha

Amamaki alandelayo anamathiselwe emshinini.

3.2. Izinyathelo Zokuphepha

Lapho usebenzisa umshini, imiyalelo nemithetho yokuphepha kufanele ilandelwe ngokucophelela.

3.2.1 Umsebenzisi kufanele abe ngabasebenzi abaqeqeshiwe nabanekhono.

3.2.2 Hlola futhi unakekele umshini ngokugcwele ngonyaka ukuze uqiniseke ukuphepha kanye nokwethembeka komshini.

3.2.3 Amandla: ibhokisi lokusabalalisa ugesi kufanele libe nesiphazamisi esinezinga elifanele lokuphepha kukagesi.

Earthing: Yonke isayithi kufanele yabelane ngocingo oluphansi olufanayo futhi uhlelo lokuxhuma phansi kufanele luqedwe futhi luhlolwe abantu abangochwepheshe.

3.2.4 Ukugcinwa komshini:

Ngezingozi ezincane zonke izinto zokusebenza kufanele zisetshenziswe ngale ndlela elandelayo:

※ Ungathinti izingxenye ze-electrophorus

※ Vimbela ukukhipha ikhebula ukuze unqamule

※ Ungabeki into esindayo noma ecijile ezintanjeni, futhi ulawule izinga lokushisa lekhebula phakathi kwezinga lokushisa elilinganiselwe (70℃)

※ Ungasebenzi endaweni emanzi. Hlola ukuthi i-groove nezicathulo zomile yini.

※ Ungachaphazi umshini

3.2.5 Hlola isimo sokufakwa komshini ngezikhathi ezithile

※ Hlola ukwahlukanisa kwezintambo ikakhulukazi amaphuzu akhishiwe

※ Ungawusebenzisi umshini ngaphansi kwesimo esibucayi.

※ Hlola ukuthi isiphazamisi sephutha lomhlabathi sisebenza kahle yini okungenani ngenyanga.

※ Hlola umhlaba womshini ngabasebenzi abaqeqeshiwe

3.2.6 Hlanza umshini ngokucophelela

※ Ungasebenzisi izinto ezilimaza ukufakwa kalula (njengegesi, i-abrasive, nezinye izincibilikisi)

※ Amandla kufanele anqanyulwe lapho kuqedwa umsebenzi.

Uma kuphela ukulandela okushiwo ngenhla, ukuqapha kungasebenza kahle.

3.2.7UKUMISA OKUPHUTHUMAYO

Kwenzeka noma yisiphi isimo esingalindelekile, sicela ucindezele okuthi “EMERGENCY STOP “ngokushesha ukuze umise umshini. Ngemva kokuxazulula izinkinga vula OKUPHUTHUMAYO MISA ngokwewashi ukuze uqale umshini futhi.

3.2.8 Ukuqina kwezingxenye:Hlola ukuthi amapayipi alungiswe kahle futhi aqinile. Qinisekisa ukuthi ayikwazi ukushelela phansi ku-opharetha wokulimala

3.2.9 Abasebenziukuphepha ngenkathi usebenza

Susa ubucwebe namaringi, futhi ayigqoki izingubo ezixegayo gwema ukugqoka ileyisi yezicathulo, amadevu amade noma izinwele ezinde ezingase ziboshwe emshinini.

3.2.10Gcina isayithi lihlanzekile futhi lihlanzekiley

Isixuku, indawo engcolile kanye ne-mussy ayikuthandi ukusebenza, ngakho-ke kubalulekile ukugcina indawo ihlanzekile futhi ihlelekile.

3.2.11 Umuntu ongaqeqeshiwe akufanele neze avunyelwe ukusebenzisa umshini noma nini.

3.3 Izingozi Ezingenzeka

3.3.1 Isaha

Lo mshini usebenza kuphela umuntu oqeqeshiwe noma izisebenzi eziqeqeshiwe, ngaphandle kwalokho kungase kudalwe ingozi engafuneki.

3.3.2 I-Saw Blade

Ungalokothi uthinte i-saha blade, noma ukulimala kungase kubangele

3.3.3 Ukusika

Ngaphambi kokusika, hlanza isihlabathi ngaphandle kwamapayipi noma enye i-draff ekhala emapayipini lapho uthutha. Lokhu kungagwema umonakalo ongadingeki we-saw blade noma ezinye izingozi

I-Range Esebenzayo Nepharamitha Yobuchwepheshe

| Uhlobo | I-TPWC-315 |

| Izinto zokusika | I-PE, PP, PVDF |

| Ubukhulu. Ukusika umthamo | 315 mm |

| I-engeli yokusika | 0°~67.5° |

| Ukunemba kwe-engeli | ≤1° |

| Isivinini somugqa we-saw blade | 230 m/min |

| Izinga lokushisa kwemvelo | -5~45℃ |

| Ukunikezwa kwamandla kagesi | ~380 V±10% |

| Imvamisa | 50 Hz |

| Isamba samanje | 5A |

| Amandla aphelele | 3.7 KW |

| Imoto yokushayela | 2.2 KW |

| I-Hydraulic unit motor | 1.5 kW |

| Ukumelana ne-insulation | >1MΩ |

| Ubukhulu. umfutho we-hydraulic | 6 MPa |

| Isisindo esiphelele (kg) | 1100 |

Izincazelo

I-band saw ingasetshenziselwa ukusika amapayipi e-PE ngokusho kwe-engeli ebekiwe lapho kwenziwa indololwane, i-tee kanye nesiphambano, ukuze umshini ube nezici zokusebenza kahle okuphezulu kanye nezinga lokusebenzisa izinto.

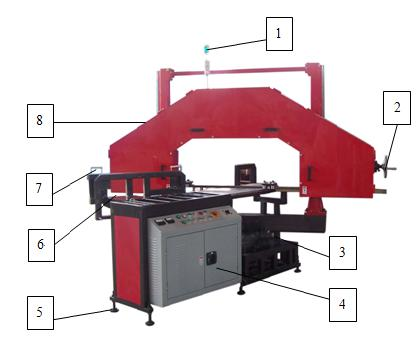

5.1 Incazelo yezingxenye

| 1. idivayisi yesixwayiso | 2. isondo lokuqina | 3.isilinganiso se-engeli | 4. ibhokisi lokulawula |

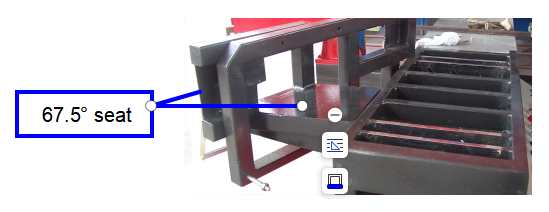

| 5. isilungisi sezinga | 6. 67.5° isihlalo | 7. lungisa idivayisi | 8.saw box |

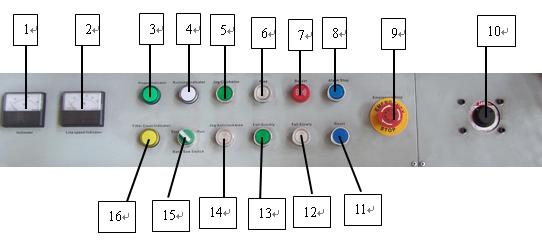

5.2 Iphaneli yokusebenza

| 1. I-Voltmeter | 2. Inkomba Yejubane Lomugqa | 3. inkomba yamandla | 4. Inkomba yokugijima |

| 5. Joja uhambisane newashi | 6. Phakama | 7. Ibhuza | 8. Ukuma kwe-alamu |

| 9. Ukuma okuphuthumayo | 10.Isilungisi sesivinini sokuphakelayo | 11. Hlela kabusha | 12. Iwa kancane |

| 13. Iwa ngokushesha | 14. jog anti clockwise | 15. I-band saw switch | 16. inkomba yokusebenza kwephampu kawoyela |

Ukufakwa

6.1 Ukuphakamisa nokufakwa

6.1.1 Uma kusetshenziswa i-forklift ngenkathi kufakwa, faka imfoloko ngokucophelela kusukela phansi komshini ukuze ugweme ukulimaza ipayipi likawoyela noma isekethe.

6.1.2 Uma ubeka umshini, umshini kufanele ugcinwe uzinzile futhi usezingeni ngokulungisa isilungisi sezinga.

6.1.3 Lo mshini ojwayelekile ungasika i-engeli 0~67.5°, uma kudingeka i-engeli engaphakathi kuka-45°, isihlalo esingu-67.5° kufanele sisuswe ngaphambi kokusebenza.

Ukusebenza

7.1 Ukuqala

7.1.1 Amandla umshini, futhi inkomba yamandla kufanele ivulwe (uma ingavuliwe, ukuxhuma akulungile).

7.2 Ukuhlolwa kwebhokisi lamasaha liya phezulu naphansi ngokuphendula isilungisi sesivinini sokuphakela kwesokudla sephaneli yokusebenza.

7.3 Cindezela inkinobho ethi “jog ngokwewashi” kanye “nenkinobho yokugijima ngokuphambene newashi ukuze uhlole isiqondiso sesaha. Uma izungeza iqonde endaweni engafanele, shintshanisa ukuxhumana phakathi kwanoma yiziphi izintambo ezimbili ezibukhoma ezixhunywe kumandla kagesi.

7.4Umsebenzi wokusika

7.4.1 Khulula isikulufu sokukhiya i-engeli, phusha i-engeli ye-engeli yokukhiya ngesandla ukuze i-engeli edingekayo (ngokwe-engeli edingekayo), bese ubophela isikulufu sokukhiya i-engeli.

7.4.2 Phakamisa ibhokisi le-saha blade libe ukuphakama (okunqunywa ububanzi bepayipi elizosikwa) ukuqinisekisa ukuthi izinyo lesaha lingaphezu kwamapayipi.

7.4.3 Beka ishubhu lokusika etafuleni lomsebenzi, lungisa indawo yokusika, futhi ulungise ipayipi ngebhande lenayiloni ngokukhiya idivayisi.

7.4.4 Qala i-blade yesaha, lapho i-saha blade ifinyelela isivinini esicacisiwe (Isikhombi sokugijima sizokhanya), vula isilungisi sesivinini sokuphakelayo ukuze iwele ibhokisi lesaha kancane. Isivinini sokuwa kufanele silawulwe ngokusho kobubanzi bepayipi nobukhulu.

7.4.5 Uma ukusika sekuzoqedwa, sicela ubambe ipayipi elinqunywe phansi ukuze ugweme ukuvimba i-saha blade.

7.4.6 Cindezela inkinobho yezimo eziphuthumayo uma kukhona okungavamile ngesikhathi sokusika. Ngemva kokuxazulula izinkinga vula OKUPHUTHUMAYO MISA ngokwewashi ukuze uqale umshini futhi..

7.4.7 I-saw blade izoma ngokuzenzakalelayo lapho ifinyelela endaweni ekhawulelwe ephansi

7.4. 8 Uma uqeda ukusika Susa ipayipi elisikiwe bese usika futhi.

7.4. 9 Lo mshini ojwayelekile ungasika i-engeli engu-0~67.5°, uma kudingeka i-engeli engaphakathi kuka-45°, isihlalo esingu-67.5° kufanele sisuswe ngaphambi kokusebenza emapayipini, kuboniswe kanje:

Isexwayiso:

1) Nika amandla umshini futhi emizuzwini engama-30 ngemuva kokunqamula amandla okuvikela isiguquli.

2) Umshini wonke kufanele ufakwe emhlabathini ukuze uqinisekise ukuphepha

3) Ukuhlolwa nokugcinwa kwezakhi zikagesi kufanele kwenziwe ngumuntu oqeqeshiwe

Amaphutha Nezixazululo

Sicela usebenzise amathuluzi anamathiselwe, izingxenye ezisele noma amanye amathuluzi anesitifiketi sokuphepha ngenkathi unakekela noma ushintsha izingxenye. Amathuluzi nezingxenye ezisele ngaphandle kwesitifiketi sokuphepha kwenqatshelwe ukusetshenziswa.

Ithebula.1 Ukwehluleka komshini

| Into | Incazelo | Ukuhlaziya | Izixazululo |

| 1 | I-band saw blade kuminyene | 1. I-engeli yesihlalo esijikelezayo ayikhiyiwe ngokuqinile. 2. I-band saw blade ayiqinisiwe ngokuqinile. 3. Isaha ligijima kancane kakhulu noma isaha liwe ngokushesha kakhulu | 1. Bopha idivayisi yokukhiya i-engeli. 2. Lawula i-tension roller ukuze iqinise i-band saw blade. 3. Yehlisa isivinini esiwayo futhi ulungise isivinini somugqa we-saha ibe phezulu. |

| 2 | I-band saw blade amaconsi | 1. Izibambi ze-saw blade azilungiswanga kahle. 2. I-band saw blade ayigxili. 3. Isondo le-saw blade liyaxegiswa. 4. Umnyombo we-valve yokuchichima uvinjelwe | 1. Lungisa isibambi seblade yesaha ukuze ulungise i-band saw blade endaweni efanele. 2. Lungisa i-tension roller ukuze iqinise i-band saw blade. 3. Bopha ngokuqinile isondo lensingo. 4. hlanza ingqikithi ye-valve yokuchichima |

Ithebula.2 Amaphutha esistimu yeHydraulic

| Into | Incazelo | Izimbangela | Izixazululo |

| 1 | Injini yephampu kawoyela ayisebenzi | 1. Oxhumana naye akavaliwe 2. Imigqa yangaphakathi inqanyuliwe 3. Injini inephutha. | 1. Hlola othintana naye; 2. Hlola uxhumano noma ipulaki. 3. Hlola futhi ulungise injini. |

| 2 | Akukho ngcindezi ohlelweni, nomsindo omkhulu kupompo | 1. Isiqondiso sokujikeleza se-oil futha motor asilungile; 2. Iphampu yenjini nekawoyela inqanyuliwe 3. Amafutha awanele noma angcole kakhulu. | 1. Kufanele ijikeleze ngokuphambene newashi; 2. Hlola coupler; 3. Gcwalisa noma ushintshe amafutha; |

| 3 | Isivinini sokuphakamisa isilinda esiyinhloko sishesha kakhulu noma sihamba kancane kakhulu | 1. Umfutho wesistimu uphezulu kakhulu noma uphansi; 2. I-valve ye-throttle ilungiswa ngendlela engafanele; 3. I-valve yesihlathi esilawulekayo ilungiswa ngendlela engafanele. | 1. Lungisa ingcindezi yesistimu; 2. Lungisa i-throttle valve; 3. Lungisa i-valve yokuqondisa eyodwa. |

| 4 | Ingcindezi ayikwazi ukulungiswa iye phezulu noma ukushintshashintsha kwengcindezi kukhulu kakhulu | 1. Umnyombo wevalvu echichimayo uvaliwe 2. Isihlungi sikawoyela sivinjiwe. 3. Umnyombo wevalvu echichimayo uvaliwe | 1. Nqamula futhi uwashe noma ushintshe i-valve yokuchichima 2. Geza isihlungi samafutha. 3 .Hlukanisa futhi uhlanze umnyombo wevalvu echichimayo. |

Umdwebo weSekethe & Hydraulic Unit Diagram

9.1 Umdwebo weyunithi yesifunda (Reference to appendix)

9.2 Umdwebo weyunithi yeHydraulic (Reference to appendix)