I-TPW200 BUTT FUSION OPERATION MANUAL

I-Range Esebenzayo Nepharamitha Yobuchwepheshe

| Uhlobo | TPWS200 |

| Izinto zokwakha | I-PE, PP kanye ne-PVDF |

| Ibanga lobubanzi × ukujiya | 200mm × 11.76mm |

| Izinga lokushisa le-ambient. | -5℃45℃ |

| Ukunikezwa kwamandla kagesi | 220V±10%, 60Hz |

| Isamba samanje | 12A |

| Amandla aphelele | 2.0 KW |

| Faka: I-Heating plate | 1.2 KW |

| Ithuluzi lokuhlela | 0.8KW |

| Ubukhulu. Izinga lokushisa | <270℃ |

| Umehluko ekushiseni okungaphezulu kwepuleti lokushisa | ± 5℃ |

| Ubukhulu. ingcindezi ye-fusion | 1040N |

| Isisindo esiphelele (kg) | 35KG |

Isingeniso Somshini

Umshini uqukethe uhlaka oluyisisekelo, ipuleti lokushisa, ithuluzi lokuhlela nokwesekwa.

Umyalelo Wokusetshenziswa

5.1 Zonke izinto zokusebenza kufanele zibekwe endizeni ezinzile neyomile ukuze zisebenze.

5.2 Ngaphambi kokuthi usebenze qinisekisa lokhu okulandelayo:

Amandla kagesi ashiwo ngokuya ngomshini wokuhlanganisa izinqe

Intambo kagesi ayiphukile noma ayigugile

Izindwani zethuluzi lokuhlela zibukhali

Zonke izinsimbi zivamile

Zonke izingxenye ezidingekayo namathuluzi ayatholakala

Umshini usesimweni esihle

5.3 Faka izinto ezifakiwe ezifanele ngokwedayamitha yangaphandle yepayipi / yokufaka

5.4 Inqubo yokushisela

5.4.1. Ngaphambi kokushisela, okokuqala, hlola ukuthi akukho yini imihuzuko noma imifantu ebusweni bamapayipi/izinsimbi. Uma ukujula kokuklwebheka noma imifantu kudlula u-10% wobukhulu bodonga, susa imihuzuko noma imifantu.

5.4.2 Hlanza indawo yangaphakathi nangaphandle yepayipi ukuze lishiselwe.

5.4.3 Beka amapayipi/izixhumi bese ugcine ubude obude bamapayipi/iziphetho ukuze zishiselwe zilingane (ngokufushane ngangokunokwenzeka). Esinye isiphetho sepayipi kufanele sisekelwe ngama-roller ukunciphisa ukungqubuzana. Bopha izikulufu zokubopha ukuze ulungise amapayipi/izixhumi.

5.4.4 Beka ithuluzi lokuhlela, ulivule bese uvala amapayipi/izixhumo ezigcina ngokusebenzisa izinduku zomshayeli ezimbili ethuluzini lokuhlela kuze kuvele ukushefa okuqhubekayo nokufana ncamashi ezinhlangothini zombili. Hlukanisa uhlaka, vala ithuluzi lokuhlela bese ulisusa. Ubukhulu be-shavings kufanele bube phakathi kuka-0.2 ~ 0.5 mm futhi bungalungiswa ngokulungisa ukuphakama kwezindwani zamathuluzi okuhlela.

6.4.5 Vala amapayipi/iziphetho zokufaka bese uhlola ukuhleleka kuka. Ukungaqondani kahle akumele kudlule u-10% wokuqina kodonga, futhi kungathuthukiswa ngokuxegisa noma ukuqinisa izikulufo zezinsimbi. Igebe phakathi kokuphela kwamapayipi amabili akufanele lidlule u-10% wodonga lokujiya; uma kungenjalo amapayipi/izinsimbi kufanele zihlelwe futhi.

5.4.6 Sula uthuli bese usika ipuleti lokushisa (Ungaklwebhi ungqimba lwe-PTFE phezu kwepuleti lokushisa).

5.4.7 Faka ipuleti lokushisisa ohlakeni ngemva kokuba selithole izinga lokushisa elidingekayo. Phakamisa ingcindezi iye phezulu ifike lapho eshiwo khona ngokuthatha isibambo kuze kube yilapho ubuhlalu bufinyelela ubude obudingekayo.

5.4.8 Yehlisa ingcindezi ibe ivelu elanele ukugcina izinhlangothi zombili zithintana nepuleti lokushisisa isikhathi esithile.

5.4.9 Uma isikhathi sesiphelile hlukanisa ifremu bese ukhipha i-heater plate, hlanganisa izinhlangothi zombili ngokushesha okukhulu.

5.4.10 Khulisa ingcindezi kuze kuvele ubuhlalu obudingekayo. Bopha idivayisi yokukhiya ukuze ugcine ukujoyina lipholile lodwa. Ekugcineni vula izinsimbi bese ukhipha ipayipi elihlangene.

5.4.11 Bheka ngokubona ilunga. I-joint kufanele ibe yi-symmetry ebushelelezi, futhi phansi kwe-groove phakathi kobuhlalu akufanele kube ngaphansi kunombhobho wepayipi. Ukungahambi kahle kobuhlalu obubili akufanele kudlule i-10% yobukhulu bodonga, noma ukushisela kubi.

I-Reference Welding Standard (DVS2207-1-1995)

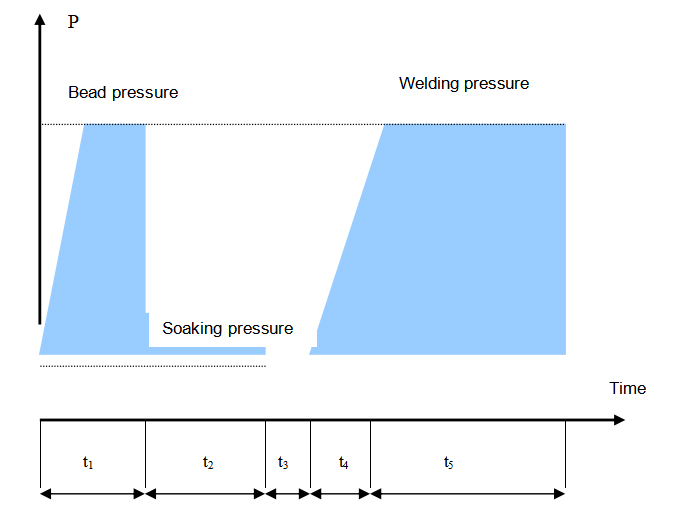

6.1 Ngenxa yokungafani kwezinga lokushisela kanye nempahla ye-PE, isikhathi nokucindezela kuyahlukahluka ngezigaba ezahlukene zokushisela. Iphakamisa ukuthi imingcele ye-welding yangempela kufanele inikezwe ngumkhiqizi wamapayipi kanye nokufakwa.

| Ukujiya kodonga (mm) | Ubude be-bead (mm) | Ingcindezi yokwakha ubuhlalu (MPa) | Isikhathi sokucwilisa t2(umzuzwana) | Ukucwiliswa kwengcindezi (MPa) | Ukushintsha kwesikhathi t3(umzuzwana) | Isikhathi sokwakha ingcindezi t4(umzuzwana) | Ingcindezi yokushisela (MPa) | Isikhathi sokupholisa t5(imizuzu) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45; 70 | ≤0.02 | 5; 6 | 5; 6 | 0.15±0.01 | 6; 10 |

| 7; 12 | 1.5 | 0.15 | 70 - 120 | ≤0.02 | 6; 8 | 6; 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8; 10 | 8; 11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26; 37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32; 45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45; 60 |

| 50-70 | 4.0 | 0.15 | 500-700 | ≤0.02 | 20 - 25 | 25-35 | 0.15±0.01 | 60-80 |

Phawula:Ingcindezi yokwakha ubuhlalu kanye nengcindezi yokushisela efomini ingcindezi yesibonisi esinconyiwe, ingcindezi yegeji kufanele ibalwe ngefomula elandelayo.

Izinkulumo:

Ingcindezi yokushisela(Mpa)=(Isigaba sepayipi lokushisela ×0.15N/mm2)/(2 ×8×8×3.14) + Hudula ingcindezi

Lapha, 1Mpha=1N/mm2