TPWC315 ISIKHOKELO SOKUSEBENZA KWEBANDLA

Inkcazo ekhethekileyo

Ngaphambi kokusebenzisa umatshini, nabani na kufuneka afunde le nkcazo ngononophelo kwaye ayigcine kakuhle ukuqinisekisa ukhuseleko lwesixhobo kunye nokhuseleko lwabanye.

2.1 Lo matshini usetyenziselwa ukusika iipayipi ezenziwe kwi-PE, PP kunye ne-PVDF kwaye ayinakusetyenziselwa ukusika izinto ezingenakuchazwa; kungenjalo umatshini unokonakala okanye ubangele ingozi.

2.2 Ungawusebenzisi umatshini kwindawo enengozi yokudubula

2.3 Lo matshini kufuneka usebenze ngabasebenzi abanoxanduva, abaqeqeshiweyo nabaqeqeshiweyo.

2.4 Umatshini kufuneka usebenze kwindawo eyomileyo. Amanyathelo okukhusela kufuneka amkelwe xa esetyenziselwa imvula okanye kumhlaba omanzi.

2.5 Amandla egalelo angaphakathi kwe-380V±10%, i-50 Hz. Ukuba umgca wokufaka owandisiweyo usetyenzisiwe, umgca kufuneka ube necandelo elikhokelayo elaneleyo.

2.6 Gcwalisa ioli ye-hydraulic (N46 ISO3448) kwitanki ngaphambi kokuqala ukusebenzisa. Umthamo weoli kufuneka ube malunga ne-2/3 yetanki.

Ukhuseleko

La manqaku alandelayo ancanyathiselwe kumatshini.

3.2. ImiGaqo yoKhuseleko

Xa usebenzisa umatshini, imiyalelo kunye nemithetho yokhuseleko kufuneka ithotyelwe ngononophelo.

3.2.1 Umqhubi kufuneka abe ngabasebenzi abaqeqeshiweyo nabanobuchule.

3.2.2 Hlola ngokupheleleyo kwaye ulondoloze umatshini ngonyaka ukwenzela ukhuseleko kunye nokuthembeka komatshini.

3.2.3 Amandla: ibhokisi yokuhambisa umbane kufuneka ibe nesiphazamisi esisezantsi esinomgangatho ofanelekileyo wokhuseleko lombane.

Earthing: Isayithi yonke kufuneka yabelane ngocingo olufanayo lomhlaba kunye nenkqubo yokudibanisa umhlaba kufuneka igqitywe kwaye ihlolwe ngabantu abaqeqeshiweyo.

3.2.4 Ukugcinwa komatshini:

Kwiingozi ezincinci zonke izixhobo kufuneka zisebenze ngolu hlobo lulandelayo:

※ Musa ukubamba iinxalenye ze-electrophorus

※ Yalela ukutsalwa ngaphandle kwentambo ukuze uqhawule

※ Musa ukubeka into enzima okanye ebukhali kwiintambo, kwaye ulawule ubushushu bekhebula ngaphakathi kokunciphisa ubushushu (70 ℃)

※ Musa ukusebenza kwindawo emanzi. Khangela ukuba i-groove kunye nezihlangu zomile.

※ Musa ukutshiza umatshini

3.2.5 Qwalasela imeko yobushushu bomatshini ngamaxesha athile

※ Jonga ukugquma kweentambo ngokukodwa amanqaku akhutshiweyo

※ Musa ukusebenzisa umatshini phantsi kweemeko ezinzima.

※ Khangela ukuba isiphazamisi somhlaba sisebenza kakuhle ubuncinane ngenyanga.

※ Jonga umhlaba womatshini ngabasebenzi abafanelekileyo

3.2.6 Coca umatshini ngononophelo

※ Musa ukusebenzisa izinto ezonakalisa ukugquma ngokulula (njengegesi, i-abrasive, kunye nezinye izinyibilikisi)

※ Amandla kufuneka anqunyanyiswe xa kugqitywa umsebenzi.

Ukuba kuphela ukulandela okukhankanywe ngasentla, isilumkiso sinokusebenza kakuhle.

3.2.7UKUMISA NGEXESHA LIKAXAKEKA

Nasiphi na isimo esingalindelekanga senzeka, nceda ucinezele “EMERGENCY STOP “ngoko nangoko ukumisa umatshini. Emva kokusombulula iingxaki jika u-EMERGENCY STOP uqalise umatshini kwakhona.

3.2.8 Ukuqina kwamalungu:Khangela ukuba imibhobho ilungiswe ngokuchanekileyo kwaye iqinile. Qinisekisa ukuba ayikwazi ukutyibilika ukuya kumqhubi wokwenzakala

3.2.9 Abasebenziukhuseleko ngelixa usebenza

Susa ubucwebe kunye nemisesane, kwaye unganxibi iimpahla ezikhululekileyo kuphephe ukunxiba iileyisi zezihlangu, amadevu amade okanye iinwele ezinde ezinokubotshelelwa kumatshini.

3.2.10Gcina indawo icocekile kwaye icocekiley

Isihlwele, indawo emdaka kunye ne-mussy ayikuthandi ukusebenza, ngoko ke kubalulekile ukugcina indawo icocekile kwaye icocekile.

3.2.11 Umntu ongaqeqeshwanga makangaze avunyelwe ukuba asebenzise umatshini nangaliphi na ixesha.

3.3 IiNgozi ezinokuthi zibe kho

3.3.1 Isarha yebhendi

Lo matshini usebenza kuphela ngumntu oqeqeshiweyo okanye abasebenzi abaqeqeshiweyo, kungenjalo ingozi engafunwayo inokubangelwa.

3.3.2 Intsimbi yokusarha

Ungaze ubambe isarha yesarha, okanye ukwenzakala kunokubangela

3.3.3 Ukusika

Ngaphambi kokusikwa, coca isanti ngaphandle kwemibhobho okanye enye idrafti ekhalayo kwimibhobho xa uthutha. Oku kunokuphepha umonakalo ongafunekiyo we-saw blade okanye ezinye iingozi

Uluhlu olusebenzayo kunye neParamitha yobuGcisa

| Uhlobo | TPWC-315 |

| Izinto zokusika | PE, PP, PVDF |

| Max. Ukusika umthamo | 315mm |

| Ukusika i-angle | 0°~67.5° |

| Ukungachaneki kwe-angle | ≤1° |

| Isantya somgca wesarha yesarha | 230 m/mz |

| Ubushushu bendawo | -5~45℃ |

| Ukunikezwa Amandla | ~380 V±10% |

| Ukuphindaphinda | 50 Hz |

| Iyonke yangoku | 5A |

| Amandla onke | 3.7 KW |

| Ukuqhuba Motor | 2.2 KW |

| Injini yeyunithi yeHydraulic | 1.5 KW |

| Ukumelana ne-insulation | >1MΩ |

| Max. uxinzelelo lwehydraulic | 6 MPa |

| Ubunzima bubonke (kg) | 1100 |

Iinkcazelo

Isarha yebhendi ingasetyenziselwa ukusika imibhobho ye-PE ngokubeka i-angle xa usenza i-elbow, i-tee kunye nomnqamlezo, ukuze umatshini uneempawu zokusebenza okuphezulu kunye nesantya sokusetyenziswa kwezinto.

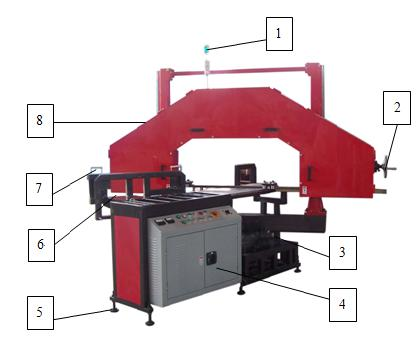

5.1 Inkcazo yamalungu

| 1. isixhobo isilumkiso | 2. ivili loxinzelelo | 3.i-angle scale | 4. ibhokisi yokulawula |

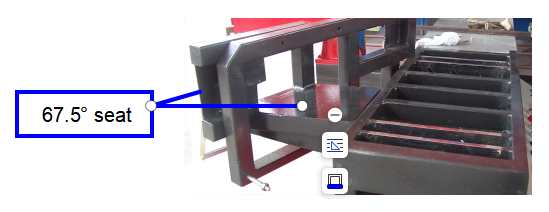

| 5. isilungelelanisi senqanaba | 6. 67.5 ° isihlalo | 7. ukulungisa isixhobo | 8.saw ibhokisi |

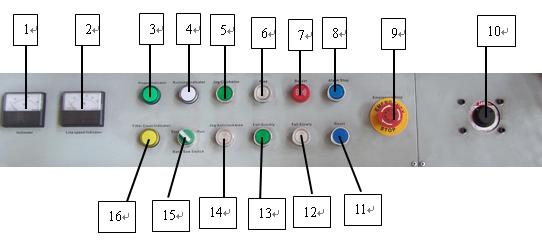

5.2 Iphaneli yokusebenza

| 1. I-Voltmeter | 2. Isalathisi sesantya somgca | 3. isalathisi samandla | 4. Isalathisi sokubaleka |

| 5. Jogi ngasekunene | 6. Phakama | 7. Buzzer | 8. Ukuma kwe-alam |

| 9. Ukuyeka ngokukhawuleza | 10.Isilungisi sesantya sokutya | 11. Lungisa kwakhona | 12. Yiwa kancinci |

| 13. Yiwa ngokukhawuleza | 14. baleka uye ngasekunene | 15. I-band saw switch | 16. isalathisi sokusebenza kwepompo yeoli |

Ukuhlohla

6.1 Ukuphakamisa kunye nokufakwa

6.1.1 Ukuba i-forklift isetyenziswe ngelixa ufaka, faka ifolokhwe ngokucophelela ukusuka ezantsi komtshini ukuphepha ukonakalisa i-hose ye-oyile okanye isiphaluka.

6.1.2 Xa ubeka umatshini, umatshini kufuneka ugcinwe uzinzile kwaye ulungelelanise umgangatho wokulungelelanisa.

6.1.3 Lo matshini oqhelekileyo unokusika i-angle 0 ~ 67.5 °, ukuba i-angle ngaphakathi kwe-45 ° iyadingeka, isihlalo se-67.5 ° kufuneka sisuswe ngaphambi kokusebenza.

Ukusebenza

7.1 Ukuqala

7.1.1 Ukunika amandla umatshini, kunye nesalathisi samandla kufuneka sivulwe (ukuba asivulwanga, unxibelelwano alulunganga).

7.2 Uvavanyo lwebhokisi yeesarha ihla inyuka ngokujika isilungelelaniso sesantya sokutya ngasekunene kwephaneli yokusebenza.

7.3 Cofa iqhosha elithi “jog clockwise” kunye “jog anticlockwise iqhosha “ukukhangela icala elibalekayo leblade yesarha. Ukuba ijikeleza kwicala elingalunganga, uqhagamshelwano lotshintshiselwano phakathi kwazo naziphi na iingcingo ezimbini eziphilileyo ezidityaniswe kunikezelo lwamandla.

7.4Umsebenzi wokusika

7.4.1 Khulula i-engile yokutshixa isikrufu, tyhala ibhokisi yencakuba yesarha ngezandla ukuya kwi-engile efunekayo (ngokweengile efunekayo), uze ubophelele isikrufu sokutshixa i-engile.

7.4.2 Phakamisa ibhokisi yeblade yesarha ibe kumphakamo (emiselwe yidayamitha yombhobho oza kusikwa) ukuqinisekisa ukuba izinyo lesarha lingaphezulu kwemibhobho.

7.4.3 Beka i-tubing yokusika kwitheyibhile yomsebenzi, ulungelelanise indawo yokusika, kwaye ulungise umbhobho ngebhanti yenylon ngesixhobo sokukhiya.

7.4.4 Qalisa i-saw blade, xa i-saw blade ifezekisa isantya esicacisiweyo (Isalathisi sokugijima siya kukhanya), jika i-adjuster yesantya sokutya ukuze iwele ibhokisi yesarha kancinane. Isantya sokuwa kufuneka silawulwe ngokuhambelana nobubanzi bombhobho kunye nobukhulu.

7.4.5 Xa kuza kugqitywa ukusika, nceda ubambe umbhobho osikiweyo ukunqanda ukuvalela isarha.

7.4.6 Cofa iqhosha likaxakeka ukuba kukho nakuphi na okungaqhelekanga okwenzeka ngexesha lokusika. Emva kokusombulula iingxaki jika u-EMERGENCY STOP ngewotshi ukuze uqalise umatshini kwakhona..

7.4.7 Ibhleyidi yesarha iya kuzimisa ngokuzenzekelayo xa ifika kwindawo esezantsi yonyino

7.4. 8 Xa ugqiba ukusika Susa umbhobho osikiweyo kwaye usike kwakhona.

7.4. 9 Lo matshini oqhelekileyo unokusika i-angle 0 ~ 67.5 °, ukuba i-angle ngaphakathi kwe-45 ° iyadingeka, isihlalo se-67.5 ° kufuneka sisuswe ngaphambi kokusebenza kwimibhobho, eboniswe ngolu hlobo lulandelayo:

Isilumkiso:

I-1) Amandla omatshini kwakhona kwimizuzu ye-30 emva kokunqumla amandla okukhusela umguquleli.

I-2) Umatshini wonke kufuneka ube nomhlaba ukuqinisekisa ukhuseleko

3) Ukutshekisha kunye nokugcinwa kwezinto zombane kufuneka kwenziwe ngumntu oqeqeshiweyo

Iimpazamo kunye nezisombululo

Nceda usebenzise izixhobo ezincanyathiselwe, iinxalenye ezisecaleni okanye ezinye izixhobo ezinesatifikethi sokhuseleko ngelixa ulungisa okanye utshintsha iindawo. Izixhobo kunye neendawo ezisecaleni ngaphandle kwesiqinisekiso sokhuseleko azivumelekanga ukuba zisetyenziswe.

Uluhlu.1 Ukusilela koomatshini

| Into | Inkcazo | Uhlalutyo | Izisombululo |

| 1 | I-Band saw blade ixingile | 1. I-angle yesitulo se-rotary ayitshixwanga ngokuqinileyo. 2. I-Band saw blade ayixinzelelwanga ngokuqinileyo. 3. Isarha isarha iyacotha kakhulu okanye isarha iwe phantsi ngokukhawuleza | 1. Qinisa isixhobo sokutshixa i-engile. 2. Lawula i-tension roller ukuze ucinezele i-band saw blade. 3. Yehlisa isantya esiwayo kwaye ulungelelanise phezulu isantya somgca wesaha. |

| 2 | I-Band saw blade amathontsi | 1. Izibambi ze-saw blade azilungiswanga kakuhle. 2. I-Band saw blade ayigxininisi. 3. I-Saw blade ivili iyakhululwa. 4. Undoqo wevalve yokuphuphuma uvalekile | 1. Lungisa isibambi se-saw blade ukulungisa i-saw blade kwindawo efanelekileyo. 2. Lungisa i-tension roller ukuze icinezele i-band saw blade. 3. Libophe ngokuqinileyo ivili lesarha. 4. coca ingundoqo yevalve yokuphuphuma |

Itheyibhile.2 Iimpazamo zenkqubo yeHydraulic

| Into | Inkcazo | Oonobangela | Izisombululo |

| 1 | Injini yempompo yeoli ayisebenzi | 1. Umnxibelelanisi akavaliwe 2. Imigca yangaphakathi iyanqanyulwa 3. Injini inempazamo. | 1. Jonga umnxibelelanisi; 2. Jonga uqhagamshelwano okanye iplagi. 3. Hlola kwaye ulungise injini. |

| 2 | Akukho xinzelelo kwinkqubo, kunye nengxolo enkulu kwimpompo | 1. Umkhombandlela wokujikeleza we-oyile yepompo yemoto ayichanekanga; 2. Isibini semoto kunye nepompo ye-oyile iqhawulwe 3. Ioyile ayonelanga okanye imdaka kakhulu. | 1. Kufuneka ijikelezise ngasekunene; 2. Jonga i coupler; 3. Gcwalisa okanye utshintshe ioli; |

| 3 | Isantya sokuphakamisa isilinda esiphambili sikhawuleza kakhulu okanye sicotha kakhulu | 1. Uxinzelelo lwenkqubo luphezulu kakhulu okanye luphantsi; 2. Ivalve ye-Throttle ilungiswa ngokungafanelekanga; 3. Ivalve ye-cheek elawulwayo ilungiswa ngokungafanelekanga. | 1. Lungisa uxinzelelo lwenkqubo; 2. Lungisa ivalve ye-throttle; 3. Lungisa ivalve yendlela enye. |

| 4 | Uxinzelelo alunakuhlengahlengiswa lube phezulu okanye ukuguquguquka koxinzelelo kukhulu kakhulu | 1. Undoqo wevalve uvalekile 2. Isihluzo se-oyile sivaliwe. 3. Undoqo wevalve uvalekile | 1. Nqamula kwaye uhlambe okanye utshintshe ivalve yokuphuphuma 2. Hlamba isihluzo se-oyile. 3 .Dibanisa kwaye ucoce i-valve engundoqo. |

ISekethe kunye neYunithi ye-Hydraulic Diagram

9.1 Idayagram yeyunithi yesekethe (Isihlomelo)

9.2 Umzobo weyunithi yeHydraulic (Ngokubhekisele kwisihlomelo)