TPWG315 380 DIGITAL PRESSURE GAGE

Ka bokhutšoane

Hammoho le thepa ea PE e tsoelang pele ho phethahala le ho phahamisa, pipe ea PE e sebelisoa haholo phepelong ea khase le metsi, ho lahla likhoerekhoere, indasteri ea lik'hemik'hale, morafo joalo-joalo.

Feme ea rona esale e ntse e etsa lipatlisiso le ho nts'etsapele mochini oa TPW oa liphaephe tsa polasetiki tse tsamaisang PE, PP le PVDF lilemo tse fetang leshome.

Kajeno, lihlahisoa tsa rona li kenyelletsa mefuta e robeli le mefuta e fetang 20 e sebetsang ho kaho ea liphaephe tsa polasetiki le ho etsa li-fittings ka har'a lithupelo ka tsela e latelang:

| SHS series socket welder | TPWC series Band saw |

| TPW letoto la mochini o kopanyang butt fusion | TPWG letoto la lithupelo mochini tjheseletsa |

| TPWY letoto la mochini o kopanyang butt | Letoto la lisebelisoa tse khethehileng |

| QZD letoto la mochini oa fusion oa Auto-butt | SHM letoto la mochini o kopanyang saddle |

Bukana ena ke ea mochini oa tjheseletsa oa lipeipi tsa polasetiki oa TPWG315. E le ho qoba kotsi ea mofuta ofe kapa ofe e bakoang ke motlakase kapa mochini. Ho khothalletsoa ho bala ka hloko le ho latela melao e latelang ea polokeho pele o sebelisa mochini.

Tlhaloso e Ikgethileng

Pele a sebelisa mochini, mang kapa mang o tlameha ho bala tlhaloso ena ka hloko le ho e boloka hantle ho netefatsa polokeho ea sesebelisoa le ts'ireletso, hammoho le polokeho ea ba bang.

2.1 Mochini o sebelisetsoa ho cheseletsa liphaephe tse entsoeng ka PE, PP, PVDF 'me o ke ke oa sebelisoa ho cheselletsa thepa ntle le tlhaloso, ho seng joalo mochini o ka senyeha kapa kotsi e itseng e ka hlaha.

2.2 Se ke oa sebelisa mochini sebakeng se nang le kotsi ea ho phatloha

2.3 Mochini o lokela ho sebetsoa ke basebetsi ba nang le boikarabelo, ba nang le tsebo le ba koetlisitsoeng.

2.4 Mochini o lokela ho sebetsoa sebakeng se omileng. Mehato ea tšireletso e lokela ho nkoa ha e sebelisoa pula kapa mobung o mongobo.

2.5 Mochini o ne o hloka 380V±10%, phepelo ea matla a 50 Hz. Haeba ho lokela ho sebelisoa thapo e atolositsoeng, ho lokela hore ho be le karolo e lekaneng ho latela bolelele ba eona.

Polokeho

3.1 matšoao a tšireletso

Lintlha tse latelang li kentsoe mochining:

3.2 Mehato ea Tlhokomeliso Bakeng sa Polokeho

Hlokomela ha o sebetsa le ho tsamaisa mochini ho latela melao eohle ea polokeho ea taelo ena.

3.2.1 Hlokomela ha u sebelisa

l Mokhanni e lokela ho ba basebetsi ba nang le boikarabelo le ba koetlisitsoeng.

l Ho hlahloba le ho hlokomela mochini ka botlalo ka selemo bakeng sa polokeho le mochini

tsepahala.

3.2.2Matla

Lebokose la kabo ea motlakase le lokela ho ba le sets'oants'o sa fatše se nang le maemo a nepahetseng a polokeho ea motlakase. Lisebelisoa tsohle tsa tšireletso li bonts'oa ka mantsoe kapa matšoao a utloisisehang habonolo.

3.2.3 Tima motlakase pele o tlosa sekwahelo sa polokeho kapa letlooa.

Khokahano ea mochini ho matla

Mochini o kopanyang thapo ho matla e lokela ho ba concussion ea mochini le bopaki ba ho bola ha lik'hemik'hale. Haeba terata e atolositsoeng e sebelisoa, e tlameha ho ba le karolo e lekaneng ea ho etella pele ho latela bolelele ba eona.

Earthing: Sebaka sohle se lokela ho arolelana terata e tšoanang ea fatše le tsamaiso ea ho hokahanya fatše e lokela ho phethoa le ho lekoa ke batho ba litsebi.

3.2.3Ho boloka thepa ea motlakase

Bakeng sa min. Likotsi, lisebelisoa tsohle li tlameha ho sebelisoa le ho bolokoa ka nepo ka tsela e latelang:

※ Qoba ho sebelisa mohala oa nakoana o sa tsamaellaneng le maemo

※ Se ke oa ama likarolo tsa electrophorus

※ Hanela ho hula thapo hore o hakoe

※ Hanela ho hula likhoele bakeng sa lisebelisoa tsa ho phahamisa

※ U se ke ua beha ntho e boima kapa e bohale holim'a likhoele, 'me u laole mocheso oa cable ka har'a mocheso o fokolang (70℃)

※ Se ke oa sebetsa sebakeng se metsi. Sheba hore na groove le lieta li omme.

※ Se ke oa fafatsa mochini

3.2.4 Nako le nako, hlahloba boemo ba mochini o kenang kahare

※ Lekola ho kenngoa ha likhoele haholo-holo lintlha tse fetisitsoeng

※ Se ke oa sebelisa mochini tlas'a maemo a feteletseng.

※ Sheba hore na sesebelisoa sa ho lutla se sebetsa hantle bonyane ka beke.

※ Lekola hore na mochini o sebetsa joang ka basebetsi ba tšoanelehang

3.2.5 Hloekisa le ho hlahloba mochini ka hloko

※ U se ke ua sebelisa lisebelisoa (tse kang abrasive, le solvents tse ling) tse senyang sekontiri habonolo ha u hloekisa mochine.

※ Etsa bonnete ba hore motlakase o khaotsoe ha o qeta mosebetsi.

※ Etsa bonnete ba hore ha ho na tšenyo leha e le efe mochineng pele o sebelisa hape.

Haeba feela ho latela se boletsoeng ka holimo, ts'ireletso e ka sebetsa hantle.

3.2.6 Ho qala

Etsa bonnete ba hore switch ea mochini e koetsoe pele o e bulela.

3.2.7 Ho tiea ha likarolo

Etsa bonnete ba hore liphaephe li tsitsitse ka nepo. Netefatsa hore e khona ho tsamaea hantle le ho e thibela ho thella.

3.2.8 Tikoloho ya mosebetsi

Qoba ho sebelisa mochine tikolohong e tletseng pente, khase, mosi le deoil, kaha tšoaetso ea mahlo le tsela ea ho hema e ne e tla bakoa.

U se ke ua beha mochine sebakeng se litšila.

3.2.9 Tšireletseho ea basebetsi ha u ntse u sebetsa

Tlosa mabenyane le mehele, 'me u se ke ua apara liaparo tse hlephileng qoba ho roala lesela la lieta, litelu tse telele kapa moriri o molelele o ka' nang oa hokelloa mochining.

3.3 Tšireletseho ea Lisebelisoa

Mochini oa welding oa Hydraulic workshop o sebetsoa feela ke setsebi kapa mosebeletsi ea nang le setifikeiti se koetlisitsoeng. Motho ea tloaelehileng a ka senya mochini kapa tse ling tse haufi.

3.3.1 Letlapa le futhumatsang

l Thempereichara ea bokaholimo ba poleiti e futhumatsang e ka fihla ho 270 ℃. Le ka mohla u se ke ua e ama ka kotloloho ho qoba ho cha.

l Pele le ka mor'a ho sebelisa, hloekisa bokaholimo ka lesela le bonolo. Qoba lisebelisoa tse senyang tse ka senyang seaparo.

l Lekola thapo ea poleiti e futhumatsang 'me u netefatse mocheso o holim'a metsi.

3.3.2 Sesebelisoa sa ho rala

l Pele o kuta liphaephe, lipheletsong tsa liphaephe li lokela ho hloekisoa, haholo-holo ho hloekisa lehlabathe kapa li-draff tse ling tse pota-potileng lipheletsong. Ka ho etsa sena, nako ea bophelo ea bohale e ka lelefatsoa, hape e thibela li-shavings ho lahleloa ho batho ba kotsi.

l Netefatsa hore sesebelisoa sa ho rala se notletsoe ka thata ka liphaephe tse peli

3.3.3 Sebopeho se seholo:

l Etsa bonnete ba hore liphaephe kapa li-fittings li tsitsitse ka nepo ho fumana tsela e nepahetseng.

l Ha o kopanya liphaephe, mosebeletsi o lokela ho boloka sebaka se itseng mochineng bakeng sa polokeho ea basebetsi.

l Pele o tsamaisa, etsa bonnete ba hore li-clamp kaofela li tsitsitse hantle 'me li ke ke tsa oela nakong ea lipalangoang.

Sebetsang Range And Technical Parameters

| Mofuta | TPWG315 | |

| Lisebelisoa tsa ho cheselletsa | PE, PP, PVDF | |

| Kantle Diameter mefuta-futa | setsoe (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm |

| tee (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| sefapano (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Wyes 45°&60° (DN,mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Mocheso oa tikoloho | ℃ 5 ~ 45℃ | |

| Oli ea Hydraulic | 40 - 50 (kinematic viscosity) limilimithara2/s, 40℃) | |

| Phepelo ea motlakase | ~380 V±10% | |

| Khafetsa | 50 Hz | |

| Kakaretso ea hajoale | 13 A | |

| Kakaretso ea matla | 7.4 KW | |

| Kenyelletsa, ho futhumatsa poleiti | 5.15 KW | |

| Enjene ea lisebelisoa tsa ho rera | 1.5 KW | |

| Hydraulic unit motor | 0.75 KW | |

| Khanyetso e sireletsang | >1MΩ | |

| Max. khatello ea metsi | 6 MPa | |

| Kakaretso ea karolo ea li-cylinders | 12.56 cm,2 | |

| Max. mocheso oa poleiti ea ho futhumatsa | 270 ℃ | |

| Phapang ka mocheso oa holim'a sejana sa ho futhumatsa | ± 7℃ | |

| Molumo o sa batleng | 70 dB | |

| Bolumo ba tanka ea oli | 55L | |

| Kakaretso ea boima ba 'mele(kg) | 995 | |

Litlhaloso

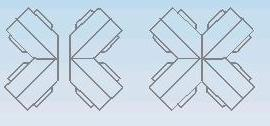

Mochini oa welding oa workshop o ka hlahisa setsoe, tee, sefapano ka pipe ea PE kopanong. Li-clamp tse tloaelehileng li lumellana le boholo ba liphaephe tse tloaelehileng ho latela ISO161/1.

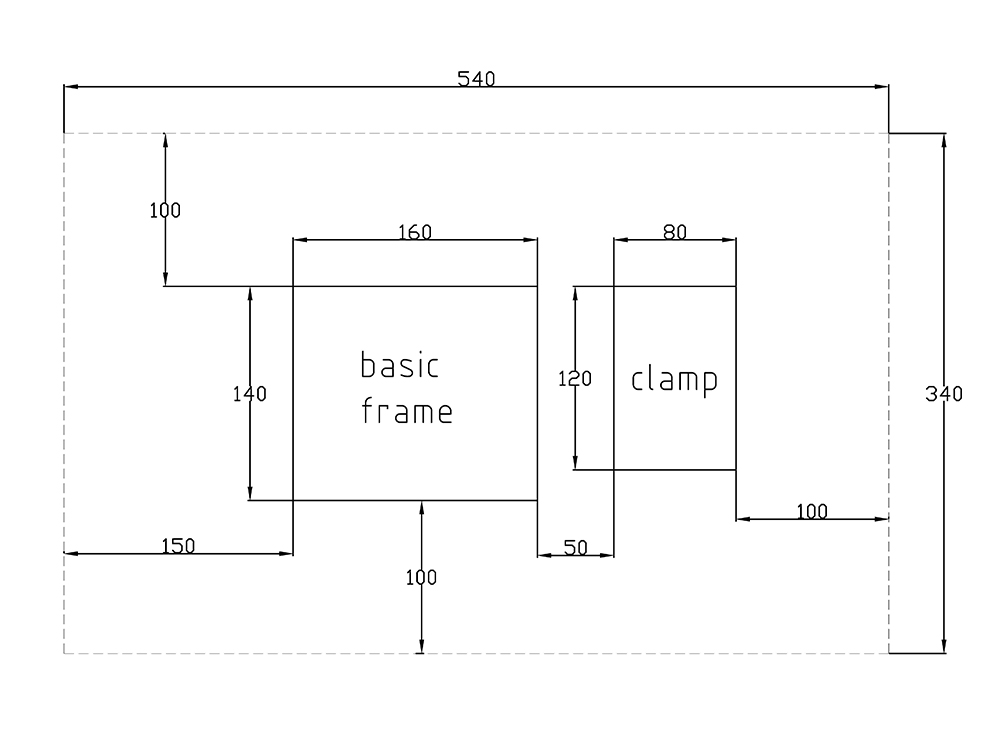

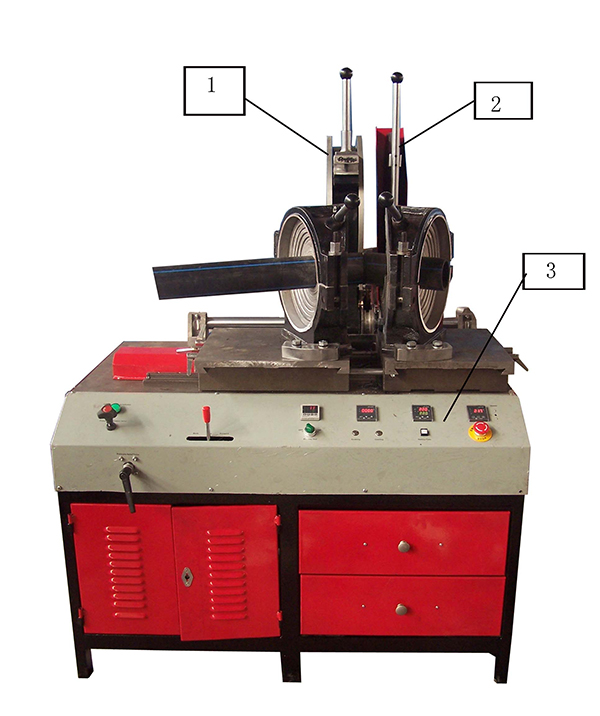

5.1 Mochini o moholo

| 1. Sesebelisoa sa moralo | 2. Letlapa le futhumatsang | 3. Phanele ea ts'ebetso |

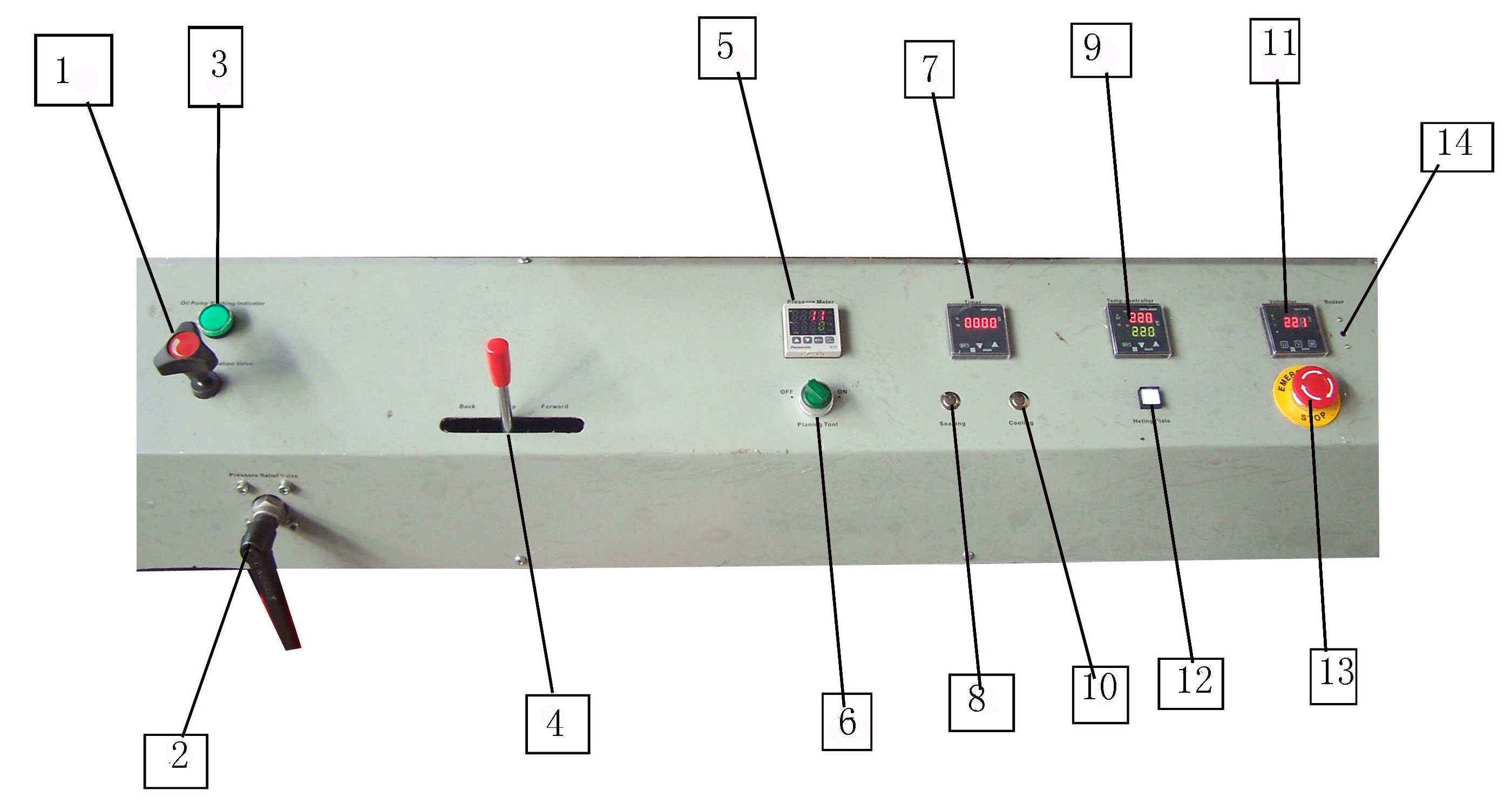

5.2 Phanele ea ts'ebetso

| 1. Khatello Regulation Valve | 2. Sehlopha sa Phallo ea Khatello | 3. Letšoao la ho sebetsa Pompe ea Oli | 4. Valofo ea Tataiso |

| 5. Digital Pressure Meter | 6. Konopo ea ho rera | 7. Sebala nako | 8. Konopo ea Nako ea ho Soaking |

| 9. Methara ea ho laola mocheso | 10. Konopo ea Nako ea ho Pholisa | 11. Voltmeter | 12. Phetoho ea ho futhumatsa |

| 13. Emergency Stop | 14. Buzzer |

Ho kenya

6.1 Ho phahamisa le ho kenya

Ha o phahamisa le ho kenya mochini o lokela ho bolokoa o otlolohile, 'me le ka mohla o se ke oa o sekamela kapa oa o khutlisa ho qoba tšenyo e sa batleheng.

6.1.1 Haeba forklift e sebelisoa, e lokela ho kenngoa ka hloko ho tloha tlase ea mochine ka hloko ho qoba ho senya hose ea oli le potoloho.

6.1.2 Ha o fetisetsa mochine sebakeng sa ho kenya, mochine o moholo o lokela ho bolokoa o tsitsitse ebile o otlolohile.

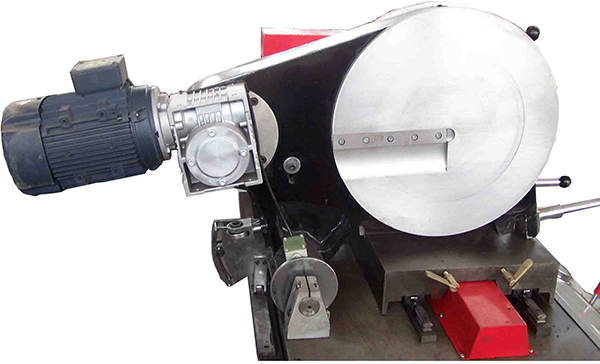

6.1.3 Kenya enjene lebokoseng la phokotso la sesebelisoa sa ho rala le ho lokisoa ka li-screws, tse bontšitsoeng ho .3.

6.2 Khokahano

Etsa bonnete ba hore sebaka se lekaneng bakeng sa ho beha mochine le ho boloka mochine oohle o otlolohile 'me u netefatse hore ho na le khokahanyo e nepahetseng ea li-sockets, lithapo le li-hose ha u kenya mochine.

6.2.1 Hokela mochine o moholo lebokoseng la motlakase.

Setšoantšo sa 4 Kopanya poleiti ea ho futhumatsa ho lebokose la motlakase

Setšoantšo sa 5 Hokela sesebelisoa sa ho rera lebokoseng la motlakase

6.2.2 Ho kopanya mohala oa mochine ho matla, e leng mekhahlelo e meraro- lithapo tse hlano 380V 50HZ.

Bakeng sa polokeho, mochini o tlameha ho koaheloa ho tloha sebakeng se tlase sa mochini.

6.2.3 Tlatsa oli ea haeteroliki e tlhotliloeng. Bophahamo ba oli e lokela ho ba ho feta 2/3 ea bophahamo ba sebaka sa gauge ea dikahare.

Tlhokomediso: Ho etsa mobu ho tlameha ho phethoa ke batho ba litsebi.

Taelo Bakeng sa ho Sebelisa

Latela melao eohle ea polokeho mochining. Motho ea sa koetlisoang ha a lumelloe ho sebelisa mochine.

7.1 Matla

Koala mosireletsi oa fatše

7.2 Qala pompo ea oli

Qala pompo ea oli ho shebella tataiso e potolohang. Haeba tekanyo ea khatello e na le lipalo, ho potoloha ho nepahetse, haeba ho se joalo, fapanyetsana lithapo tse peli tse phelang.

7.3 Sheba 'me u fetole khatello ea ho hula le ho tsamaisa lebelo la poleiti ea ho hula. Khatello ea ts'ebetso ea sistimi ke 6 MPa. Khatello e kopanetsoeng e ka fetoloa ka valve ea taolo ea khatello e teng holim'a phanele ea taolo. Khatello ea ho rera e lokela ho eketseha butle-butle, 'me e boloke ha li-shavings tse tsoelang pele li hlaha (eseng tse kholo haholo). Lebelo la fepa la poleiti ea ho hula le ka fetoloa ka valve ea ho hlahloba (ka hare ho setsi).

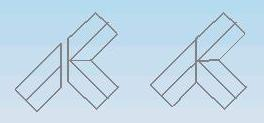

7.4 Ho kenya Li-clamps

Kenya litulo tsa li-clamp tse ka ho le letšehali le ka ho le letona (li-clamp bakeng sa li-tee kapa li-elbows) ho latela lisebelisoa tse tla etsoa.

1) Li lokise pele ka senotlolo sa senotlolo se kopantsoeng le mochini;

2) Fetola angle ka ho sebetsana le sebaka se khethehileng;

3) Tiisa sekoti sa senotlolo ka sekoahelo.

Haeba liqhomane tsa setsoe li ne li hloka ho sebelisoa, li hatelle ka thata ka senotlolo ka mor'a ho lokisa angle.

7.5 Beha mocheso o boletsoeng ho molaoli oa mocheso ho latela mokhoa oa ho tjheseletsa phala. (Sheba karolo ea 7.10)

7.6 Pele o phahamisa kapa o theolela sesebelisoa sa ho rala bula sesebelisoa sa senotlolo se sehokelong.

7.7 Liphaephe tse kenang mochining

7.7.1 Arola li-clamps tsa mochine ka ho sebetsa holim'a lever ea valve ea tataiso

7.7.2 Beha lipeipi ka har'a li-clamp 'me u li fase; sebaka pakeng tsa lipheletsong tse peli tsa liphaephe e lokela ho ba ho lekaneng bakeng sa planing sesebelisoa.

7.7.3 Valofo ea ho fokotsa khatello ea senotlolo, ha u ntse u koala lipheletsong tse peli, fetola valve ea taolo ea khatello ho fihlela tekanyo ea khatello e bontša khatello ea fusion, e khethiloeng ke lisebelisoa tsa liphaephe.

7.8 Ho rera

7.8.1 Arola li-clamp ka ho sebelisa valve ea tataiso le valve e bulehileng ka ho feletseng ea ho fokotsa khatello.

7.8.2 Beha sesebelisoa sa ho rala lipakeng tsa liphaephe tse peli le ho bulela, atamela liphaephe ho ea ho sesebelisoa sa ho rera ka ho sebelisa valve ea tataiso "pele", 'me u lokise valve e laolang khatello ho boloka khatello e loketseng ho fihlela litelu tse tsoelang pele li hlaha ho tloha ho tse peli. mahlakoreng.Hlokomela: 1) Botenya ba li-shavings bo lokela ho ba ka hare ho 0.2 ~ 0.5mm 'me bo ka fetoloa ka ho lokisa bolelele ba sesebelisoa sa ho rala.

2) Khatello ea moralo ha ea lokela ho feta 2.0 MPa ho qoba tšenyo ea sesebelisoa sa moralo.

7.8.3 Ka mor'a ho rera, Arola li-clamp 'me u tlose sesebelisoa sa moralo.

7.8.4 Koala mahlakore a mabeli ho a matahanya. Haeba ho se lumellane ho feta 10% ea botenya ba phala, e ntlafatse ka ho lokolla kapa ho tiisa li-clamps tse ka holimo. Haeba lekhalo pakeng tsa lipheletsong le feta 10% ea botenya ba lerako la phala, lokisa phala hape ho fihlela o fumana se hlokahalang.

7.9 Welding

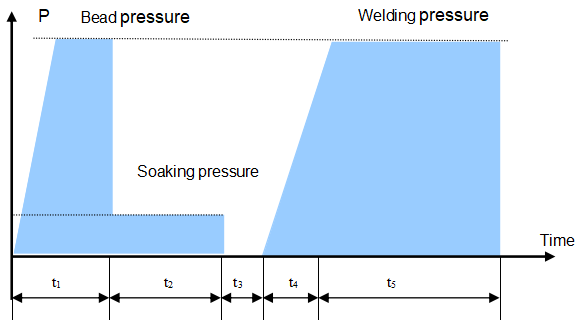

7.9.1 Beha nako ea ho koloba le nako ea ho pholile ho latela mokhoa oa ho cheselletsa.

7.9.2 Kamora ho tlosa sesebelisoa sa planing, beha poleiti ea ho futhumatsa, notlela butle-butle valve ea khatello ea khatello ha u ntse u sutumelletsa pele valve ea tataiso, e eketsang khatello ea mocheso ho khatello ea fusion e boletsoeng.1). Lipheletso tsa phala li khomarela poleiti ea ho futhumatsa 'me motsoako oa qala.

7.9.3 Ha sefaha se senyenyane se ntse se hola, sutumelletsa morao valve ea tsela e bohareng ho boloka khatello. Fetola valve ea swing ho theola khatello ea khatello ea metsi (P2) ebe o e notlela kapele. Ebe o tobetsa konopo ea nako ea ho kenella ka nako.

7.9.4 Ka mor'a ho koloba (li-alarm tsa buzzer), bula li-clamps ka ho sebelisa valve ea tataiso 'me u tlose poleiti ea ho futhumatsa kapele.

7.9.5 Kopanya lipheletsong tse peli tse qhibilihisitsoeng ka potlako 'me u boloke valve ea tataiso "pele" ka nako e khutšoanyane ebe u khutlela sebakeng se bohareng ho boloka khatello. Ka nako ena, ho baloa ka tekanyo ea khatello ke khatello ea fusion e behiloeng (haeba ho se joalo, e fetole ka ho sebetsa ka valve ea taolo ea khatello).

7.9.6 Tobetsa konopo ea nako ea ho pholisa ha pholile e qala. Ka mor'a hore nako ea ho phomola e fete, buzzer e lla. Hlakola khatello ea sistimi ka ho sebetsa ka valve ea ho imolla khatello, bula li-clamps le ho tlosa manonyeletso.

7.9.7 Sheba lenonyeletso ho latela litekanyetso tsa ts'ebetso ea welding.

7.10 Selaoli sa mocheso le nako

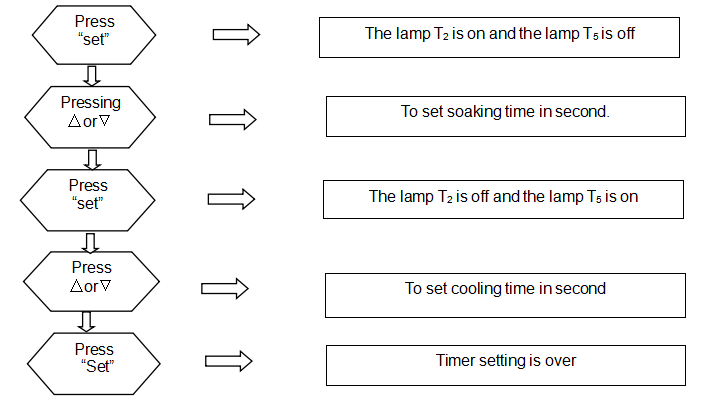

7.10.1 Tlhophiso ea nako

7.10 Selaoli sa mocheso le nako

7.10.1 Tlhophiso ea nako

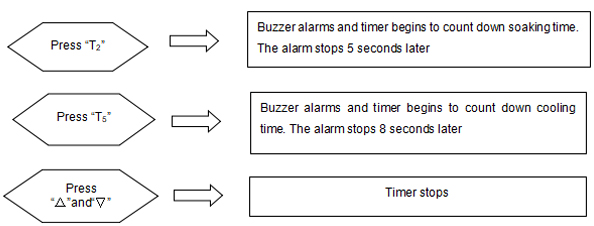

7.10.2 Nako e sebelisoang

7.10.3 Tlhophiso ea taolo ea mocheso

1) Tobetsa "SET" bakeng sa metsotsoana e fetang 3 ho fihlela "sd" e bontšoa fensetereng e ka holimo

2) Tobetsa "∧" kapa "∨" ho fetola boleng ho mocheso o boletsoeng (tobetsa "∧" kapa "∨" u sa khaotse, boleng bo tla eketsa kapa bo tlose ka bohona)

3) Kamora ho beha, tobetsa "SET" ho khutlela ho sehokelo sa ho beha leihlo le ho laola

Reference Welding Standard (DVS2207-1-1995)

8.1 Ka lebaka la litekanyetso tse fapaneng tsa welding le lisebelisoa tsa PE, nako le khatello ea mohato oa ts'ebetso ea fusion li fapane. E fana ka maikutlo a hore litekanyetso tsa ho cheselletsa li lokela ho pakoa ka liphaephe le lisebelisoa tse entsoeng

8.2 Fuoa tjheseletsa mocheso oa liphaephe entsoe ho tloha PE, PP le PVDF ka DVS maemo a ranges ho tloha180 ℃ ho 270 ℃. Mocheso oa ts'ebeliso ea poleiti ea ho futhumatsa o ka har'a 180~230℃, le Max oa eona. mocheso holim'a metsi o ka fihla ho 270 ℃.

8.3 Tekanyetso ea litšupisoDVS2207-1-1995

| Botenya ba lebota (mm) | Bolelele ba lifaha (mm) | Khatello ea ho haha lifaha (MPa) | Nako ea ho noa t2(Motsotsoana) | Khatello ea metsi (MPa) | Ho fetoha ha nako t3(metsotsoana) | Nako ea ho eketsa khatello t4(metsotsoana) | Khatello ea welding (MPa) | Nako ea ho pholisa t5(mets) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45-70 | ≤0.02 | 5 - 6 | 5 - 6 | 0.15±0.01 | 6-10 |

| 7-12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6 - 8 | 6 - 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8-10 | 8-11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26-37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32-45 |

| 37-50 | 3.5 | 0.15 | 370 ~ 500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45-60 |

| 50-70 | 4.0 | 0.15 | 500 ~ 700 | ≤0.02 | 20-25 | 25-35 | 0.15±0.01 | 60-80 |

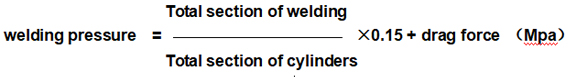

Tlhokomeliso: Khatello ea ho haha lifaha le khatello ea welding ka sebopeho ke khatello e khothaletsoang ea sebopeho, khatello ea gauge e lokela ho baloa ka foromo e latelang.

Mokhoa oa ho Lokisetsa ho Lokisa

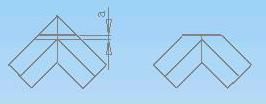

9.1 Ho etsa litsoe

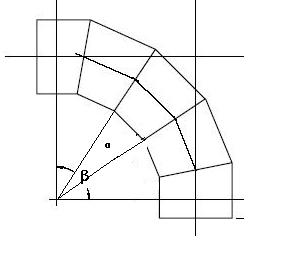

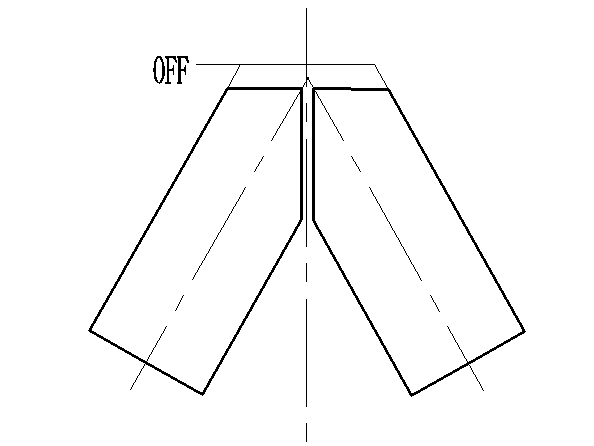

9.1.1 Ho ea ka angle ea setsoe le bongata ba likarolo tsa welding, angle ea welding pakeng tsa karolo e 'ngoe le e 'ngoe e ka etsoa qeto.

Tlhaloso: α - welding angle

β - angle ea setsoe

n - bongata ba likarolo

Ka mohlala: 90 ° setsoe e arotsoe ka likarolo tse hlano tse lokelang ho chesetsoa, lehlakoreng la ho cheselletsa α=β/(n-1)=90°/(5-1)=22.5°

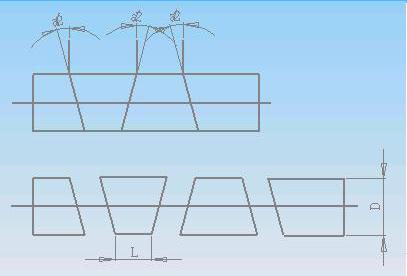

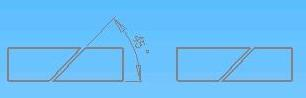

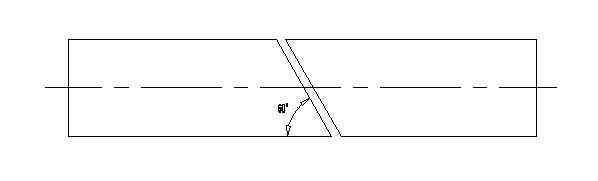

9.1.2 The min dimension ea karolo e 'ngoe le e 'ngoe ea tjheseletsa likarolong tse ngata tsa welding e khaoloa ke sakha ea band ho latela angle.

Tlhaloso:

D - bophara bo ka ntle ba phala

L - Min bolelele ba karolo e 'ngoe le e 'ngoe

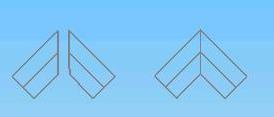

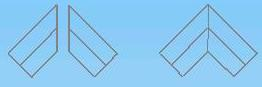

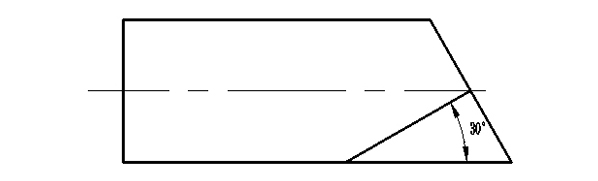

9.2 Mokhoa oa ho hlahisa bacha

9.2.1 Lisebelisoa li tšoana le setšoantšo se latelang:

9.2.2 Welding joalo ka sebopeho sa setšoantšo:

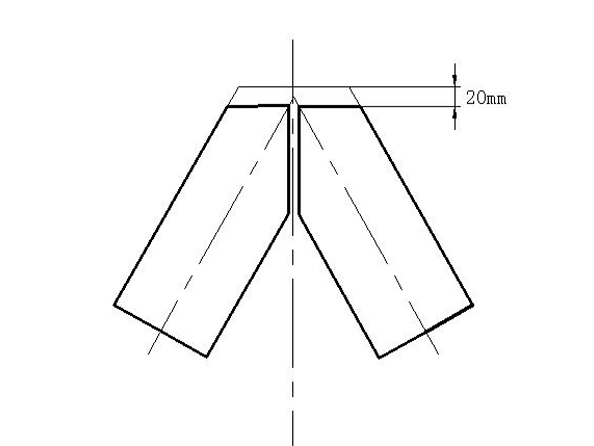

9.2.3 Lehlakore le sehiloe joalo ka setšoantšo

Tlhokomeliso: Boemo "a" ha boa lokela ho ba ka tlase ho 20㎜e leng joalo ka moralo oa moeli le ho lefa sefaha se qhibilihang.

9.2.4 Welding e le sebopeho sa setšoantšo, li-tee li entsoe.

9.3 Mokhoa oa ho etsa liphaephe tse fapaneng tsa bophara bo lekanang

9.3.1 Lisebelisoa li khaoloa joalo ka setšoantšo se latelang

9.3.2 Li-couplers tse peli li cheselitsoe joalo ka sebopeho sa setšoantšo:

9.3.3 Akele e sehiloe joalo ka setšoantšo:

Tlhokomeliso: Boemo "a" ha boa lokela ho ba ka tlase ho 20㎜, E rerang moeli le ho lefa sefaha se qhibilihang.

9.3.4 Welded e le sebopeho sa setšoantšo.

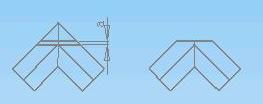

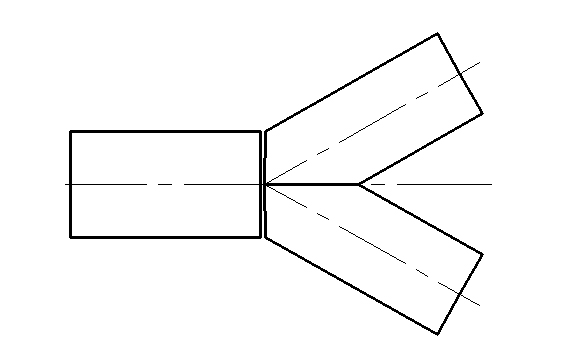

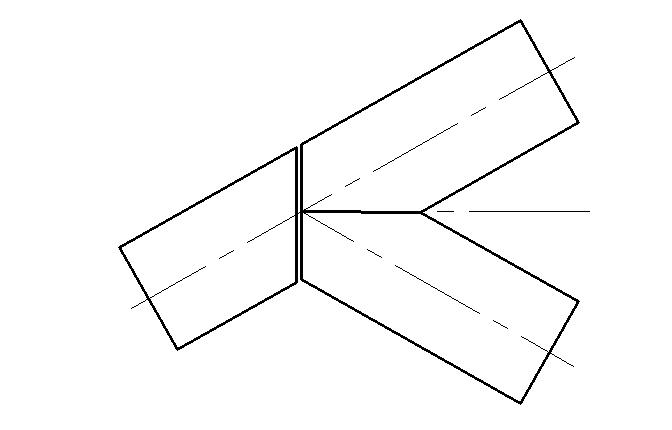

9.4 Mokhoa oa ho etsa li-fittings tsa sebopeho sa "Y" (45 ° kapa 60 °)

9.4.1 seha joalo ka setšoantšo se latelang (nka mohlala oa 60 ° "Y"

9.4.2 Tsoela pele ho tjheseletsa ea pele joalo ka litšoantšo tse latelang:

9.4.3 Fetola li-clamps 'me u tsoele pele ho tjheseletsa ea bobeli.

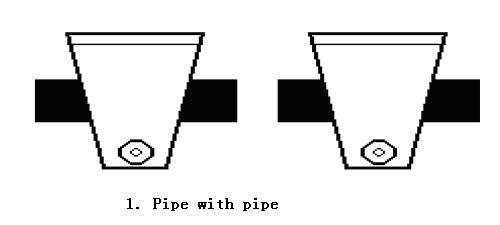

9.5 fittings tse ling tse tjheseletsa

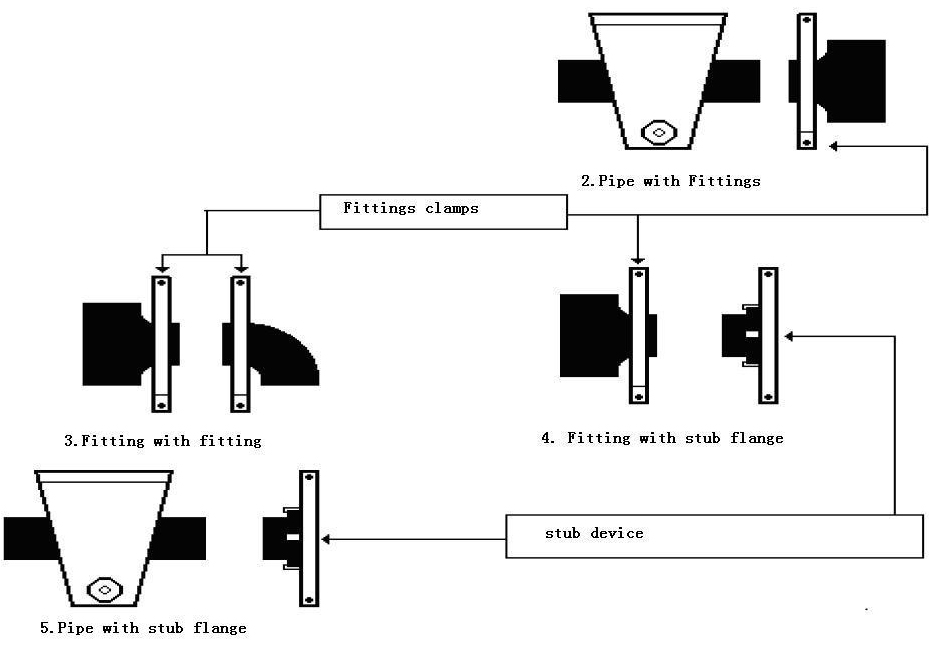

9.5.1. Pipe e nang le phala

9.5.2. Pipe e nang le ho kenya

9.5.3 Ho kenya letsoho

9.5.4 Ho kenya flange ea stub

9.5.5 Pipe e nang le stub flange

Mefunctions Analysis And Solutions

10.1 Mathata a khafetsa a boleng ba manonyeletso a sekaseka:

10.2 Tlhokomelo

u PTFE tlotsitsoe ho futhumatsa poleiti

Ka kopo hlokomela ho tšoara seipone se futhumatsang e le ho qoba tšenyo ea ho roala PTFE.

Kamehla u hloekise libaka tse koahetsoeng ka PTFE, ho hloekisa ho lokela ho etsoa ka holimo ho ntse ho futhumetse ka ho sebelisa lesela le bonolo kapa pampiri, ho qoba lisebelisoa tse senyang tse ka senyang libaka tse koahetsoeng ke PTFE.

Ka linako tse ling, re u khothaletsa:

- Hloekisa bokaholimo ka ho sebelisa sesepa se potlakileng sa mouoane (joala)

- Lekola ho tiisa ha li-screw le thapo le boemo ba plug

u Sesebelisoa sa ho rera

Ho khothaletsoa ka matla ho boloka li-blades kamehla li hloekile le ho hlatsoa li-pulleys ka ho sebelisa sesepa.

Nako le nako etsa ts'ebetso e felletseng ea ho hloekisa ka lubrication ea kahare

yuniti ea Hydraulic

Setsi sa hydraulic ha se hloke tlhokomelo e khethehileng leha ho le joalo litaelo tse latelang li tlameha ho lateloa:

a. Nako le nako, hlahloba oli e otlolohileng 'me haeba u ka eketsa mofuta oa oli:

Sebaka se otlolohileng ha sea lokela ho ba ka tlase ho 5 cm ho tloha tanka e tšekaletseng.

Ho hlahlojoa ka matsatsi a mang le a mang a 15 ho khothaletsoa ka matla.

b. Tlosa oli ka botlalo likhoeling tse ling le tse ling tse 6 kapa kamora lihora tse 630 tsa ho sebetsa.

c. Boloka hydraulic unit e hloekile ka tlhokomelo e khethehileng holim'a tanka le likhokahano tse potlakileng.

10.3 Litlhahlobo le tharollo ea ho se sebetse khafetsa

Nakong ea ts'ebeliso, hydraulic unit le li-unit tsa motlakase li ka hlaha mathata a mang. Ho se sebetse hantle hangata ho thathamisitsoe ka tsela e latelang:

Ka kopo sebelisa lisebelisoa tse khomaretsoeng, likarolo tse ling kapa lisebelisoa tse ling tse nang le setifikeiti sa polokeho ha u ntse u lokisa kapa u fetola likarolo. Lisebelisoa le likarolo tse ling tse se nang setifikeiti sa polokeho li thibetsoe ho sebelisoa.

| Ho se sebetse hantle ha hydraulic unit | |||||

| No | ha e sebetse hantle | sekaseka | tharollo | ||

| 1 | Enjene ha e sebetse |

e hlephile

| |||

| 2 | Enjene e potoloha butle haholo ka lerata le sa tloaelehang |

| ho feta 3 MPa

| ||

| 3 | Silinda e sebetsa ka mokhoa o sa tloaelehang |

notletsoe ka thata

| ho tsoa moyeng. | ||

| 4 | Silinda e tsamaisang poleiti ha e sebetse |

valve e koetsoe |

valve e phallang (1.5 MPa e nepahetse).

| ||

| 5 | Moqomo o lutla | 1. Lesale la oli le na le phoso2. Silinda kapa piston e senyehile hampe | 1. Kenya sebaka sa lesale la oli2. Tlosa silinda | ||

| 6 | Khatello e ke ke ea eketseha kapa ho feto-fetoha ha maemo ho hoholo haholo | 1. Moko oa valve oa ho phalla o koetsoe.2. Pompo e dutla.3. Ho thella ho kopaneng ha pompo hoa theoha kapa key groove ke skid. | 1. Hloekisa kapa u nke sebaka sa valve ea coreof over-flow2. Fetola pompo ea oli3. Kenya sebaka sa lenonyello slack | ||

| 7 | Khatello ea ho itšeha e ke ke ea fetoloa | 1. Potoloho ke phoso2. Mohala oa motlakase o na le phoso3. The valve overflow e thibetsoe4. Ho khaola valve ea ho phalla ha hoa tloaeleha | 1. Lekola potoloho (diodein e khubelu khoele ea makenete ea motlakase ea khanya)2. Kenya sebaka sa coil ea electromagnetic3. Hloekisa karolo ea mantlha ea valve ea ho phalla ho feta4. Lekola valve ea ho itšeha ka holimo | ||

| Ho se sebetse hantle ha likarolo tsa motlakase | |||||

| 8 | Mochine oohle ha o sebetse |

| 1. Sheba thapo ea motlakase2. Lekola matla a sebetsang3. Bula mosireletsi oa fatše | ||

| 9 | Maeto a ho fetola liphoso tsa fatše |

| 1. Sheba lithapo tsa motlakase2. Lekola likarolo tsa motlakase.3. Lekola sesebelisoa sa polokeho ea matla se holimo holimo | ||

| 10 | Mocheso o ntseng o eketseha ka tsela e sa tloaelehang |

4. 4. Na lipalo tsa mocheso oa mocheso li feta 300 ℃, tse fanang ka maikutlo a hore sensor ea hae e ka senyeha kapa khokahano e lokolohile. Na molaoli oa mocheso o lokela ho bontša LL, e leng se bontšang hore sensor e na le potoloho e khutšoanyane. Haeba molaoli oa mocheso o lokela ho bonts'a HH, e fanang ka maikutlo a hore potoloho ea sensor e bulehile. 5. Lokisa mocheso ka konopo e teng ho molaoli oa mocheso.

| likhokahanyo

molaoli

beha mocheso

contactors haeba ho hlokahala | ||

| 11 | Ho lahleheloa ke taolo ha ho futhumatsa | Leseli le khubelu lea khanya, empa mocheso o ntse o nyoloha, ke hobane sehokelo se na le phoso kapa manonyeletso a 7 le a 8 ha a khone ho bula ha a fumana mocheso o hlokahalang. | Kenya sebaka sa taolo ea mocheso | ||

| 12 | Sesebelisoa sa ho rera ha se potoloha | Moeli oa switjha ha o sebetse kapa likarolo tsa mochini tsa sesebelisoa sa ho rala li koetsoe. | Fetola moeli oa sesebelisoa sa ho rera switch kapa sprocket e nyane | ||

Potoloho & Hydraulic Unit Diagram

11.1 Setšoantšo sa yuniti ea potoloho (e bonoang sehlomathisong)

11.2 Setšoantšo sa yuniti ea Hydraulic (e bonoang sehlomathisong)

Chate ea Mosebetsi oa Sebaka