TPW200 BUTT FUSION MACHINE MANUAL OPERATIONS

Range e sebetsang le Parameter ea tekheniki

| Mofuta | TPWS200 |

| Lisebelisoa | PE, PP le PVDF |

| Boholo ba bophara × botenya | 200 limilimithara × 11.76 limilimithara |

| Mocheso oa tikoloho. | -5℃45℃ |

| Phepelo ea motlakase | 220V±10%, 60Hz |

| Kakaretso ea hajoale | 12A |

| Kakaretso ea matla | 2.0 KW |

| Kenyelletsa: Letlapa le futhumatsang | 1.2 KW |

| Sesebelisoa sa ho rera | 0.8 KW |

| Max. Mocheso | <270℃ |

| Phapang ka mocheso oa holim'a sejana sa ho futhumatsa | ± 5℃ |

| Max. khatello ea fusion | 1040N |

| Kakaretso ea boima ba 'mele (kg) | 35KG |

Selelekela sa Mochini

Mochine o na le foreimi ea motheo, poleiti ea ho futhumatsa, sesebelisoa sa moralo le tšehetso.

Taelo Bakeng sa ho Sebelisa

5.1 Thepa eohle e lokela ho behoa sefofaneng se tsitsitseng le se omeletseng ho sebetsa.

5.2 Pele o sebetsa etsa bonnete ba lintho tse latelang:

Phepelo ea motlakase ke e boletsoeng ho latela mochini o kopanyang butt

Mohala oa motlakase ha o robehe kapa oa khathala

Maqhubu a sesebelisoa sa ho rera a bohale

Lisebelisoa tsohle li tloaelehile

Likarolo tsohle tse hlokahalang le lisebelisoa li teng

Mochine o maemong a matle

5.3 Kenya lintho tse kenyellelitsoeng ho latela bophara bo ka ntle ba phaephe/fitting

5.4 Mokhoa oa ho cheselletsa

5.4.1. Pele ho tjheseletsa, pele, hlahloba hore na ho na le mengoapo kapa maphao holim'a liphaephe / lisebelisoa. Haeba botebo ba mengopo kapa maphao bo feta 10% ea botenya ba lebota, tlosa mengoallo kapa maphao.

5.4.2 Hloekisa bokaholimo ba lipeipi bo ka hare le bo kantle hore bo chesetsoe.

5.4.3 Beha lipeipi/li-fittings 'me u boloke bolelele bo bolelele ba liphaephe/li-fittings li lokela ho ts'oaroa li lekana (tse khutšoane kamoo ho ka khonehang). Qetello e 'ngoe ea phala e lokela ho tšehetsoa ke li-roller ho fokotsa likhohlano. Tlama li-screws tsa li-clamps ho lokisa liphaephe/li-fittings.

5.4.4 Beha sesebelisoa sa ho rera, se bulela 'me u koale liphaephe/li-fittings ka ho sebelisa lithupa tse peli tsa mokhanni khahlanong le sesebelisoa sa ho rera ho fihlela litelu tse tsoelang pele le tse tšoanang li hlaha mahlakoreng ka bobeli. Arola foreimi, tima sesebelisoa sa ho rera 'me u se tlose. Botenya ba li-shavings bo lokela ho ba ka hare ho 0.2 ~ 0.5 mm mme bo ka fetoloa ka ho fetola bolelele ba lisebelisoa tsa lisebelisoa.

6.4.5 Koala liphaephe / lipheletso tse kenyellelitsoeng 'me u hlahlobe tsela. Ho se tsamaisane hantle ha hoa lokela ho feta 10% ea botenya ba lebota, 'me e ka ntlafatsoa ka ho lokolla kapa ho tiisa li-screws tsa li-clamps. Lekhalo pakeng tsa liphaephe tse peli ha lea lokela ho feta 10% ea botenya ba lerako; ho seng joalo lipeipi / li-fittings li lokela ho hlophisoa hape.

5.4.6 Hlakola lerōle 'me u petsole poleiti ea ho futhumatsa (U se ke ua ngwapa PTFE layer holim'a poleiti ea ho futhumatsa).

5.4.7 Beha poleiti ea ho futhumatsa ka foreiming ka mor'a hore e fumane mocheso o hlokahalang. Phahamisa khatello ho ea ho e boletsoeng ka ho sebetsa ka letsoho ho fihlela sefaha se fihla bophahamong bo hlokahalang.

5.4.8 Fokotsa khatello ho boleng bo lekaneng ho boloka mahlakore ka bobeli a tšoarane ka poleiti ea ho futhumatsa nako e behiloeng.

5.4.9 Ha nako e felile arola foreime 'me u tlose poleiti ea ho futhumatsa, kopanya mahlakoreng a mabeli kapele kamoo ho ka khonehang.

5.4.10 Eketsa khatello ho fihlela sefaha se hlokahalang se hlaha. Koala sesebediswa sa senotlolo ho boloka lenonyeletso le ipholela ka bolona. Qetellong bula li-clamps 'me u ntše phala e kopantsoeng.

5.4.11 Sheba ka mahlo lenonyeletso. Lenonyeletso le lokela ho ba le symmetry e boreleli, 'me tlase ea groove pakeng tsa lifaha ha ea lokela ho ba tlase ho feta bokaholimo ba phala. Ho se lumellane ha lifaha tse peli ha hoa lokela ho feta 10% ea botenya ba lerako, kapa welding e mpe.

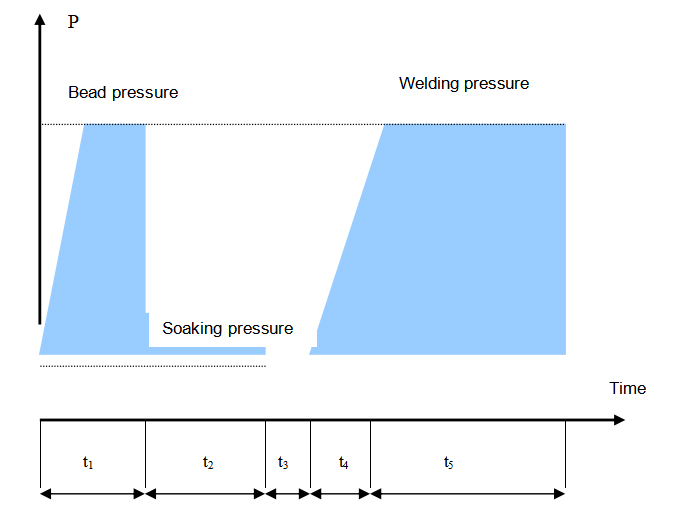

Reference Welding Standard (DVS2207-1-1995)

6.1 Ka lebaka la liphapang tsa litekanyetso tsa welding le lisebelisoa tsa PE, nako le khatello li fapana ka mekhahlelo e fapaneng ea welding. E fana ka maikutlo a hore li-parameter tsa sebele tsa welding li lokela ho fanoa ke moetsi oa liphaephe le li-fittings.

| Botenya ba lebota (mm) | Bolelele ba lifaha (mm) | Khatello ea ho haha lifaha (MPa) | Nako ea ho noa t2(metsotsoana) | Khatello ea metsi (MPa) | Ho fetoha ha nako t3(metsotsoana) | Nako ea ho eketsa khatello t4(metsotsoana) | Khatello ea welding (MPa) | Nako ea ho pholisa t5(mets) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45-70 | ≤0.02 | 5 - 6 | 5 - 6 | 0.15±0.01 | 6-10 |

| 7-12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6 - 8 | 6 - 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8-10 | 8-11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26-37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32-45 |

| 37-50 | 3.5 | 0.15 | 370 ~ 500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45-60 |

| 50-70 | 4.0 | 0.15 | 500 ~ 700 | ≤0.02 | 20-25 | 25-35 | 0.15±0.01 | 60-80 |

Tlhokomeliso: Khatello ea ho haha lifaha le khatello ea welding ka sebopeho ke khatello e khothaletsoang ea sebopeho, khatello ea gauge e lokela ho baloa ka foromo e latelang.

Litlhaloso:

Khatello ea ho cheselletsa(Mpa)=(Karolo ea phala ea welding ×0.15N/mm2)/(2 ×8×8×3.14) + Hula khatello

Mona,Mpa 1=1N/mm2