TPWY630/400 BUTT FUSION MACHINE OPERATION Manual

Inoshanda Range Uye Unyanzvi Parameter

| Type | TPWY-630/400 |

| Zvishandiso | PE, PP uye PVDF |

| Range yedhayamita | 400㎜~630㎜ |

| Ambient temp. | -5~45℃ |

| Magetsi | 380 V±10%, 50Hz |

| Total power | 12.2 Kw |

| Kusanganisira: Heating plate | 9.2 Kw |

| Planning tool | 1.5Kw |

| Hydraulic unit | 1.5Kw |

| Max. Pressure | 6.3 Mpa |

| Chikamu chose chemasilinda | 23.06 cm2 |

| Hydraulic mafuta | YA-N32 |

| Max. Tembiricha | <270℃ |

| Kusiyana kwekushisa kwekupisa ndiro interface | ±7℃ |

| Huremu hwese, Kg | 635 |

Tsanangudzo Yakakosha

Isu tinokurudzira kuverenga zvinyorwa zvese nekungwarira kuti uchengetedze mushandisi uye chengetedzo yemidziyo usati watanga kushandisa muchina. Iri bhuku rekushandisa rinofanirwa kuchengetwa nemazvo kuti rizoshandiswa mune ramangwana.

3.1 Mudziyo uyu haukodzere pasina kutsanangura zvinhu pombi welding; zvikasadaro zvinogona kukuvadza kana kuitika tsaona.

3.2 Usashandise muchina munzvimbo ine ngozi inoputika.

3.3 Muchina uyu unofanirwa kushandiswa nenyanzvi.

3.4 Muchina unofanirwa kushandirwa panzvimbo yakaoma. Matanho ekudzivirira anofanira kutorwa kana ashandiswa mumvura inonaya kana pavhu rakanyorova.

3.5 Simba rekuisa iri 380V±10%, 50Hz. Kana ukashandisa mutsara wekupinza wekuwedzera, mutsara unofanirwa kuva nechikamu chekutungamira chakakwana.

Applications Tsanangudzo Yezvikamu

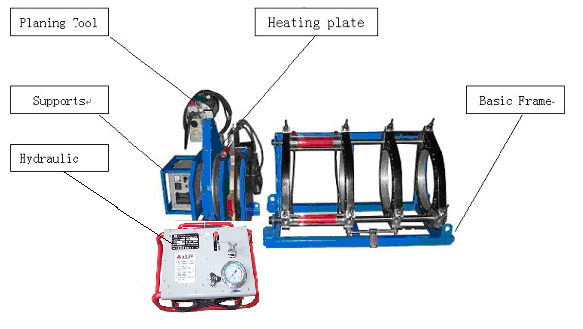

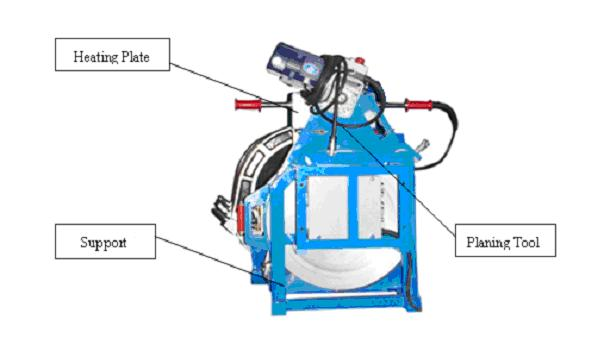

Muchina uyu unoumbwa kubva kune basic frame, hydraulic unit, heat plate, planing tool, tsigiro yeplaning tool uye bhokisi remagetsi.

4.1 gadziriso yemuchina

4.2 Basic frame

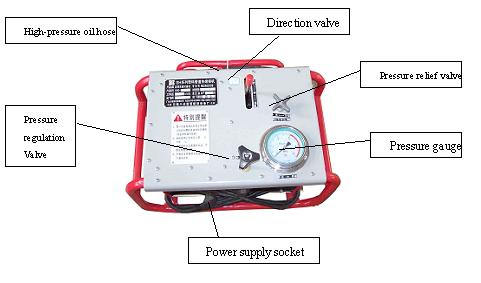

4.3 hydraulic zvikamu

4.4 Kuronga chishandiso uye kupisa ndiro

Murayiridzo Wekushandisa

5.1 Zvikamu zvese zvemidziyo zvinofanirwa kuiswa pane yakatsiga uye yakaoma ndege kuti ishande.

5.2 Ita shuwa kuti simba rinoenderana nebutt fusion muchina wakumbirwa, muchina uri mumamiriro ezvinhu akanaka, tambo yemagetsi haina kuputsika, zviridzwa zvese zvakajairika, mashizha emidziyo yekuronga akapinza, zvikamu zvese zvinodiwa uye maturusi zvakakwana.

5.3 Hydraulic uye yemagetsi kubatana

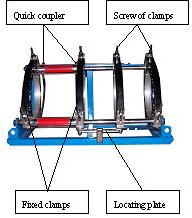

5.3.1 batanidza iyo yakakosha furemu nehydraulic unit nekukurumidza coupler.

5.3.2 batanidza tambo yekudziya ndiro kune yemagetsi bhokisi mune yakakosha furemu.

5.3.3 batanidza mutsara weplate yekupisa kune inopisa ndiro.

5.3.4 Isa zvinoiswa zvinoenderana nekunze kwepaipi/kukodzera kune yekutanga furemu.

5.4 Welding maitiro

5.4.1 Tarisa dhayamita nekukora kwemadziro kana SDR yemapombi/mafittings kuti ave welding akarurama. Kumusoro kwaro kunofanira kutariswa kusati kwatanga kupinza, kana kukwenya kunopfuura 10% yemadziro ukobvu, kunofanira kunge kuri kucheka chidimbu kushandisa.

5.4.2 Geza mukati nekunze pamusoro pepombi inoperera kuti isimbiswe.

5.4.3 Isai mapaipi/mafittings mumapuremu, kureba kwepombi/mafittings anogumisira ave welded achibuda kunze kwekuisa pamwe akafanana (apfupi sezvinobvira). Imwe mugumo wepombi inofanira kutsigirwa nema rollers kuderedza kukwesha. Wobva wapukuta sikuruu yezvisungo kuti ubate mapaipi/kukodzera.

5.4.4 Isa mudziyo wepuranga mufuremu pakati pepombi/mafittings ekupedzisira uye wobatidza, vhara mapombi/fittings inogumira nekushandisa nzira vharafu yehydraulic unit kusvika pave nekuveura kunoramba kuripo kumativi ese.(kuveura kudzvinyirira kuri pasi pe2.0 Mpa). Isa bhara revhavha panzvimbo yepakati uye chengeta masekondi mashoma, wobva wavhura furemu, dzima mudziyo wekugadzira uye woibvisa kunze kwefuremu. Ukobvu hwemashavings hunofanirwa kunge huri 0.2 ~ 0.5 mm uye hunogona kugadziriswa nekugadzirisa kureba kwemashizha emidziyo yekuronga.

5.4.5 Vhara pombi/kupinza magumo uye ongorora kusarongeka kwawo. The max. Misalignment haifanire kudarika 10% yehukobvu hwemadziro, inogona kuvandudzwa nekugadzirisa pombi kurongeka uye kusunungura kana kuomesa screws ye clamps. Mukaha pakati pemigumo yepombi mbiri haifanire kudarika 10% yemadziro emadziro, kana kuti inofanira kutemwa zvakare.

5.4.6 Bvisa guruva uye urambe uri mundiro yekudziya (Usakwenya PTFE layer pamusoro pendiro yekudziya).

5.4.7 Isa ndiro yekudziya mufuremu pakati pepombi inopera mushure mekunge tembiricha inodiwa yasvika. Simuka kumanikidza kusvika painodiwa kusvika bead yasvika kureba chaiko.

5.4.8 Deredzai kudzvinyirira kune kukosha kunokwana kuchengetedza migumo miviri yepombi / fittings inosangana nepureti yekupisa yenguva yekunyura inodiwa.

5.4.9 Kana nguva yakwana, vhura furemu wotora ndiro yekudziisa, vhara mativi maviri anonyungudika nekukasira.

5.4.10 Wedzera kudzvanywa kusvika kune welding pressure uye chengetedza mubatanidzwa kusvika panguva yekutonhora. Rerutsira kumanikidzwa, sunungura screw ye clamps uye tora iyo yakabatanidzwa pombi.

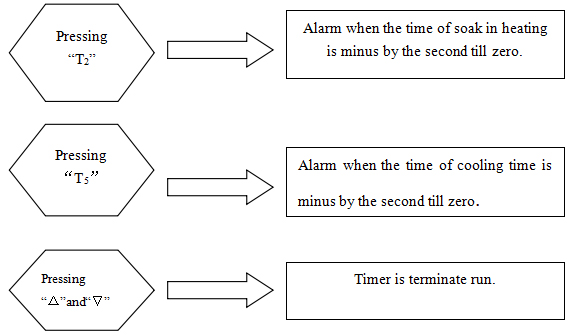

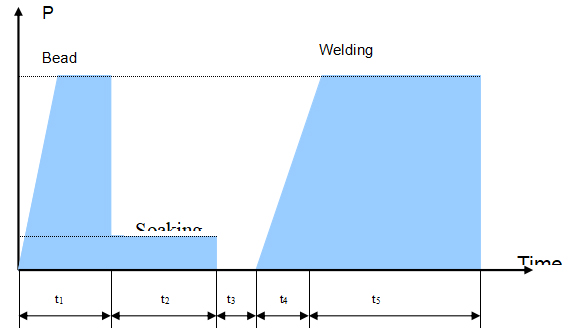

Timer Instrument

Kana imwe yeparameter ikashandurwa, senge dhayamita yekunze, SDR kana zvinhu zvepombi, iyo soak munguva yekudziya uye nguva yekutonhora inofanira kugadziridzwa zvinoenderana neyakajairwa welding.

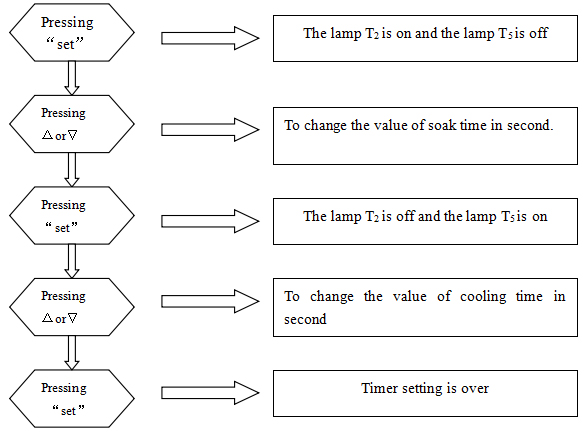

6.1 Kugadzirisa nguva

6.2 Murairo Wekushandisa

Welding Standard Uye Tarisa

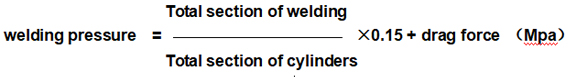

7.1 Nekuda kweakasiyana welding standard uye PE zvinhu, iyo nguva uye kumanikidzwa kwechikamu chebutt fusion process zvakasiyana. Inopa zano kuti mapaipi anofanirwa kuratidza iwo chaiwo welding ma paramita uye magadzirirwo emagetsi.

7.2 Reference standardDVS2207-1-1995

| Kukora kwemadziro (mm) | Bead urefu (mm) | Bead pressure (Mpa) | Kunyura nguva t2(Sekondi) | Kunyura pressure (Mpa) | Kuchinja-nekufamba kwenguva t3(Sekondi) | Kusimuka nguva t4(Sekondi) | Welding pressure (Mpa) | Nguva yekutonhodza t5(min) |

| 0~4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45~70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7~12 | 1.5 | 0.15 | 70~120 | ≤0.02 | 6~8 | 6~8 | 0.15±0.01 | 10~16 |

| 12~19 | 2.0 | 0.15 | 120~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16~24 |

| 19~26 | 2.5 | 0.15 | 190 -260 | ≤0.02 | 10~12 | 11~14 | 0.15±0.01 | 24~32 |

| 26~37 | 3.0 | 0.15 | 260~370 | ≤0.02 | 12~16 | 14~19 | 0.15±0.01 | 32~45 |

| 37~50 | 3.5 | 0.15 | 370~500 | ≤0.02 | 16~20 | 19~25 | 0.15±0.01 | 45~60 |

| 50~70 | 4.0 | 0.15 | 500~700 | ≤0.02 | 20~25 | 25~35 | 0.15±0.01 | 60~80 |

Remark:

Matauriro:

Advert Kuenderera Kwekuchengetedza

Zvinokurudzirwa kuverenga uye kunyatsotevera zvinotevera zvakachengeteka mitemo usati washandisa muchina.

8.1 Vashandisi vehunyanzvi vanofanirwa kudzidziswa vasati vashandisa nekushandisa muchina.

8.2 Muchina unofanirwa kuongorora nekugadzirisa uye kushandisa makore maviri apfuura kune yakachengeteka side.

8.3 Simba: Iyo plug yemagetsi inopihwa nemutemo wekuchengetedza kune vane hunyanzvi vanoshanda uye kuchengetedza muchina.

Nzvimbo yakachengeteka inofanira kunge ine izwi kana nhamba kuitira kuti zvizivikanwe.

Batanidza nemuchina uye simba: Simba rekuisa iri 380±20V ye50Hz. Kana ukashandisa mutsara wekupinza wekuwedzera, mutsara unofanirwa kuva nechikamu chekutungamira chakakwana.

Grounding: Inofanirwa kunge iine chiratidzo chekufambisa chemutsara panzvimbo yekuvaka, kupikisa nekuisa pasi sutu yekudzivirira kuseta uye kuona kuti haipfuure makumi maviri neshanu voltage uye kuseta kana kuyedzwa nemagetsi.

Kuchengetera magetsi: Muchina uyu unofanirwa kunge uchinyatso kushandisa chengetedzo kuitira kuchengetedza.

Batanidza nemuchina unofanirwa kubvunza unoshanda mutemo.

※ Dzivisa chero rudzi rwetsaona inokonzerwa nemagetsi.

※ Dzivisa kucheka magetsi nekudhonza

※ Dzivisa kufamba, dhonza uye isa muchina netambo-mutsara.

※ Dzivisa kumucheto uye uremu patambo-mutsara, tembiricha yetambo-tambo haifanire kudarika 70 ℃.

※ Muchina unofanirwa kushandirwa panzvimbo yakaoma. Matanho ekudzivirira anofanira kutorwa kana ashandiswa mumvura inonaya kana pavhu rakanyorova.

※ Nzvimbo yekushanda inofanira kunge yakachena.

※ Muchina unofanirwa kuongororwa uye kugadzirisa nguva yenguva.

※ Nguva nenguva tambo-mutsara weiyo insulation inofanirwa kuongorora uye kuve yakakosha kudzvanywa

※ Zvine njodzi kushandisa muchina kana kuchinaya kana mumamiriro egorosi.

※ Residual ikozvino yakashanda yedunhu breaker inofanirwa kugadziriswa nemwedzi.

※ Mugadziri wemagetsi anofanirwa kuongorora kudzika kwechimiro.

※ Kana uchichenesa muchina nekuchenjerera, usaite machira emuchina kana kushandisa benzine, isina pamuviri uye zvichingodaro.

※ Muchina uyu unofanirwa kuchengetedza mu deiccation yemamiriro.

※ Ese mapulagi anofanirwa neplug kunze kubva kune magetsi.

※ Kushandiswa kwemichina yapfuura, muchina unofanirwa kugara uri mukushanda kwakanaka.

Zvinokurudzira kuverenga uye kutevedzera zvakachengeteka mitemo usati washandisa muchina.

Njodzi yekutanga-up: muchina usati washandiswa, plug yemagetsi inopihwa nekuchengetedza.

Mapombi anomira mumushini:

Isa mapaipi mukati mezvisungo uye uzvisungirire, chinhambwe chepombi mbiri inopera inofanira kuisa mudziyo wekuronga uye inshuwarisi yekushanda, dzivisa chero njodzi inokonzerwa nemagetsi uye inoshandiswa.

Kushanda kwemamiriro:

Kushanda kwenzvimbo kunofanirwa kuve kwakachena, kuoma uye kwakavhenekerwa zvakakodzera.

Zvine njodzi kushandisa muchina kana kuchinaya kana gorosi kana padyo nemvura inopfuta.

Chenjerera kuti vanhu vese vakatenderedza muchina vari pakachengeteka chinhambwe.

Hembe:

Chengetedza kutarisirwa kwakanyanya paunenge uchishandisa muchina nekuda kwekupisa kwakanyanya kunowanikwa pandiro yekudziya nguva dzose kupfuura 200 ℃, zvinokurudzirwa kushandisa magurovhosi akakodzera. Dzivisa hembe refu uye dzivirira zvishongo, nekiresi inogona kusungirirwa mumushini.

Cherechedza Ngozi Uye Dzivirira Tsaona

Iyo butt fusion muchina:

Kushandiswa kwemuchina kunofanirwa kuve nehunyanzvi hunoitwa.

※ Iyo inopisa ndiro

Iyo yekudziya ndiro nekuda kwekupisa kwakanyanya kupfuura 270 ℃, zvinokurudzirwa kutora chiyero:

---shandisa magirovhosi anopisa

---mushure mebutt fusion pombi nepombi, ndiro yekudziya inofanira kuiswa.

--- akapedza kupisa ndiro inofanira kunge iri pabhokisi.

---inobvumidzwa kuti isabate pane inodziya ndiro.

※ Chishandiso chekuronga

--- before Scraping operation, mapaipi uye pasi kudzivirira kusvibisa mapaipi akatarisana anopera.

--- akapedza chishandiso chekuronga chinofanira kunge chiri paRutsigiro rwekuronga mudziyo & kupisa ndiro.

※ Basic furemu

---takatanga kare kuti yakakosha furemu pane yataurwa pamusoro ichibatanidza Iyo' yakakodzera marudzi ese epombi kune pombi welding.

--- paunenge uchitanga kushanda chengetedza kudzivirira kusiya makumbo kana maoko zvinofambiswa. Zvinosungirwa kuve kure kubva kune yekutanga furemu.

--- chenjera kuti vanhu vese vakatenderedza muchina vari pakachengeteka chinhambwe.

---vashandisi vehunyanzvi vanofanirwa kuchengeta mitemo yekuchengetedza.

Maintenance

| Item | Tsanangudzo | Wongorora usati washandisa | Mwedzi wekutanga | Mwedzi mitanhatu yese | Gore negore |

| Planning tool | Dzorera blade kana kuputika zvakare Tarisa kana tambo yakapwanyika Tarisa kana mechanical connection yaregererwa |

●

|

● | ● ●

| |

| Kupisa ndiro | Tarisa tambo uye masokisi majoini Yakachena nzvimbo yekudziya ndiro, dzokorora PTFE layer zvakare kana zvichidikanwa Tarisa kana mechanical connection yaregererwa | ● ●

|

● |

●

| |

| Temperature control system | Checkout tembiricha chiratidzo Tarisa kana tambo yakapwanyika |

● | ● ● | ||

| Hydraulic system | Checkout pressure gauge Tarisa kuti kubatana kwepombi yeoiri kwakadonha, simbisa zvakare kana kutsiva zvisimbiso Chenesa sefa Tarisa mafuta kana asina Shandura mafuta Tarisa kana hose yemafuta yakaputsika |

●

●

● |

●

| ●

● ●

| |

| Basic Frame | Tarisa kana iyo yekuomesa sikuru mumagumo eforemu axis yakasunungurwa Pfaya antirust pendi zvakare kana zvichidikanwa |

●

|

●

|

●

|

● |

| Simba Supply | Dzvanya bhatani rekuyedza redunhu mudziviriri kuti utarise kuti muchengeti wedunhu akajairika kushanda Tarisa kana tambo yakapwanyika | ● ● |

● |