TPWG315 380 DIGITAL PRESSURE GAUGE

Muchidimbu

Pamwe chete nemidziyo yePE zvinhu zvinoenderera mberi nekunatsa uye kusimudza, PE pombi inoshandiswa zvakanyanya mugasi uye kugovera mvura, kuraswa kwetsvina, indasitiri yemakemikari, yangu uye zvichingodaro.

Fekitori yedu yanga ichitsvaga nekugadzira TPW yakatevedzana mapurasitiki pombi butt fusion muchina wakakodzera PE, PP, uye PVDF anopfuura makore gumi.

Nhasi, zvigadzirwa zvedu zvinosanganisira marudzi masere uye anopfuura makumi maviri marudzi anoshanda kune epurasitiki pombi kuvaka uye kugadzira mafittings mumusangano sezvinotevera:

| SHS yakatevedzana socket welder | TPWC series Band saw |

| TPW yakatevedzana bhuku butt fusion muchina | TPWG yakatevedzana workshop welding muchina |

| TPWY yakatevedzana butt fusion muchina | Series zvakakosha zvishandiso |

| QZD yakatevedzana Auto-butt fusion muchina | SHM yakatevedzana saddle fusion muchina |

Iri bhuku ndere TPWG315 epurasitiki pombi workshop welding muchina. Kuti udzivise chero mhando yetsaona inokonzerwa nemagetsi kana mechanical. Zvinokurudzirwa kuverenga nokungwarira uye kutevedzera inotevera kuchengetedzwa mitemo usati washandisa muchina.

Tsanangudzo Yakakosha

Asati ashandisa muchina, chero munhu anofanirwa kuverenga tsananguro iyi nekuchenjerera uye kuichengeta zvakanaka kuti ave nechokwadi chekuchengetedzwa kwemidziyo uye kuchengetedzwa kwemushandisi, pamwe nekuchengetedzwa kwevamwe.

2.1 Muchina uyu unoshandiswa kubatanidza pombi dzakagadzirwa kubva kuPE, PP, PVDF uye haugone kushandiswa kugadzira zvinhu pasina tsananguro, zvikasadaro muchina unogona kukuvara kana imwe tsaona ingakonzereswa.

2.2 Usashandise muchina uri panzvimbo ine njodzi inogona kuputika

2.3 Muchina uyu unofanirwa kushandiswa nevashandi vane mutoro, vane hunyanzvi uye vakadzidziswa.

2.4 Muchina unofanirwa kushandirwa panzvimbo yakaoma. Matanho ekudzivirira anofanira kutorwa kana ashandiswa mumvura inonaya kana pavhu rakanyorova.

2.5 Muchina waida 380V±10%, 50Hz magetsi. Kana tambo yekuwedzera ichishandiswa, panofanirwa kuve nechikamu chakakwana zvinoenderana nehurefu hwadzo.

Safety

3.1 kuchengetedza mamaki

Mavara anotevera akaiswa pamushini:

3.2 Chengetedzo Yekuchengetedza

Chenjerera paunenge uchishanda uye kutakura muchina zvinoenderana nemitemo yese yekuchengetedza mune iyi rairo.

3.2.1 Cherechedza paunenge uchishandisa

l Mushandi anofanirwa kuve nehanya uye akadzidziswa vashandi.

l Nyatsoongorora uye chengetedza muchina pagore kuitira kuchengetedza uye muchina

kuvimbika.

3.2.2Simba

Bhokisi rekugovera magetsi rinofanirwa kunge riine chigumbuso chepasi chine chiyero chekuchengetedza magetsi. Yese midziyo yekudzivirira inoratidzirwa nemashoko anonzwisisika kana mamaki.

3.2.3 Dzima magetsi usati wabvisa chivharo chekuchengetedza kana mambure.

Kubatanidzwa kwemuchina kune simba

Iyo tambo yekubatanidza muchina kune simba inofanirwa kunge iri mechanical concussion uye chemical corrosion proof. Kana tambo yakatambanudzwa yakashandiswa, inofanira kuva nechikamu chakakwana chekutungamira maererano nehurefu hwayo.

Earthing: Iyo saiti yese inofanirwa kugovera imwechete pasi waya uye iyo yekubatanidza pasi system inofanirwa kupedzwa uye kuedzwa nevanhu vane hunyanzvi.

3.2.3Kuchengetwa kwemidziyo yemagetsi

Nokuti min. njodzi, zvishandiso zvese zvinofanirwa kushandiswa uye kuchengetwa nemazvo sezvinotevera:

※ Regedza kushandisa waya yenguva isingaenderane neyakajairwa

※ Usabate electrophorus zvikamu

※ Rambidza kudhonza kubva patambo kuti ubvise

※ Rambidza kudhonza tambo dzemidziyo yekusimudza

※ Usaise chinhu chinorema kana chakapinza patambo, uye kudzora tembiricha yetambo mukati mekudzikamisa tembiricha (70 ℃)

※ Usashande munzvimbo ine mvura. Tarisa kana groove neshangu zvaoma.

※ Usasasa muchina

3.2.4 Tarisa mamiriro ekudzivirira emuchina nguva nenguva

※ Tarisa kuvharwa kwetambo kunyanya mapoinzi akawedzerwa

※ Usashandise muchina uri pasi pemamiriro akanyanya.

※ Tarisa kana iyo leakage switch ichishanda zvakanaka kanenge pasvondo.

※ Tarisa pasi pemuchina nevashandi vanokwanisa

3.2.5 Chenesa uye tarisa muchina nemazvo

※Usashandise zvinhu (senge abrasive, uye zvimwe zvinonyungudutsa) zvichikuvadza kuvharisa zviri nyore paunenge uchichenesa muchina.

※ Ita shuwa kuti simba rakabviswa kana wapedza basa.

※ Ita shuwa kuti hapana kukuvadzwa mumushini usati washandisa zvakare.

Kana kungotevera zvataurwa pamusoro apa, kungwarira kunogona kushanda zvakanaka.

3.2.6 Kutanga

Ita shuwa kana switch yemuchina yakavharwa usati waibatisa.

3.2.7 Kusimba kwezvikamu

Iva nechokwadi chokuti mapaipi akaiswa zvakanaka. Ita shuwa kuti inogona kufamba zvakanaka uye kudzivirira kuti isatsvedza pasi.

3.2.8 Nzvimbo yekushanda

Dzivisa kushandisa muchina munzvimbo izere pendi, gasi, utsi uye deoil, sezvo kutapukirwa nemaziso uye kufema turakiti zvingakonzerwa.

Usaise muchina munzvimbo ine tsvina.

3.2.9 Kuchengetedzwa kwevashandi pavanenge vachishanda

Bvisa zvishongo nemhete, uye usapfeke zvipfeko zvinoregedzera dzivirira kupfeka tambo dzeshangu, ndebvu refu kana vhudzi refu rinogona kusungirirwa muchina.

3.3 Equipment Kuchengetedza

Hydraulic workshop welding machine inongoshandiswa nenyanzvi kana mushandi ane chitupa chakadzidziswa. Munhu asina basa anogona kukanganisa muchina kana zvimwe zviri pedyo.

3.3.1 Kupisa ndiro

l Kupisa kwepamusoro kwendiro yekudziya kunogona kusvika 270 ℃. Usamboibata zvakananga kudzivirira kutsva

l Usati washandisa uye wapedza, chenesa pasi nejira rakapfava. Dzivisa abrasive zvinhu zvinogona kukuvadza coating.

l Tarisa tambo yekudziya ndiro uye uone tembiricha yepasi.

3.3.2 Kuronga mudziyo

l Usati waveura mapaipi, migumo yepombi inofanira kucheneswa, kunyanya kuchenesa jecha kana imwe dhizaini yakarira kumativi. Nekuita izvi, hupenyu hwemupendero hunogona kurebeswa, uye zvakare kudzivirira shavings inokandwa kunze kune njodzi vanhu.

l Vimbiso yekuronga chishandiso yakakiyiwa zvakasimba nemativi maviri epombi

3.3.3 Mainframe:

l Ita shuwa kuti mapaipi kana mafittings akagadziriswa nemazvo kuti awane kurongeka kwakaringana.

l Pakujoinha mapaipi, mushandisi anofanirwa kuchengetedza imwe nzvimbo kumuchina kuitira kuchengetedza kwevashandi.

l Usati watakura, ita shuwa kuti mabhanhire ese akagadziriswa zvakanaka uye haagone kuwira pasi panguva yekufambisa.

Inoshanda Range Uye Unyanzvi Parameters

| Type | TPWG315 | |

| Zvishandiso zvewelding | PE, PP, PVDF | |

| Kunze Diameter ranges | gokora (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm |

| tee (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| muchinjikwa (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Wyes 45°&60° (DN,mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Kupisa kwenzvimbo | -5~45℃ | |

| Hydraulic mafuta | 40 ~ 50 (kinematic viscosity) mm2/s, 40℃) | |

| Magetsi | ~380 V±10 % | |

| Frequency | 50 Hz | |

| Total current | 13 A | |

| Total power | 7.4 KW | |

| Batanidza, kupisa ndiro | 5.15 KW | |

| Kuronga chishandiso mota | 1.5 KW | |

| Hydraulic unit mota | 0.75 KW | |

| Insulating resistance | >1MΩ | |

| Max. hydraulic pressure | 6 MPa | |

| Chikamu chose chemasilinda | 12.56 cm2 | |

| Max. tembiricha yekudziya ndiro | 270 ℃ | |

| Kusiyana kwekushisa kwepamusoro kweplate yekupisa | ± 7℃ | |

| Inzwi risingadiwi | <70 dB | |

| Tangi remafuta Volume | 55L | |

| Huremu hwese(kg) | 995 | |

Tsanangudzo

Welding welding muchina unogona kugadzira gokora, tee, kuyambuka ne PE pombi pamusangano. Iwo akajairwa machirambi anoenderana neakajairwa mapaipi 'saizi zvinoenderana ne ISO161/1.

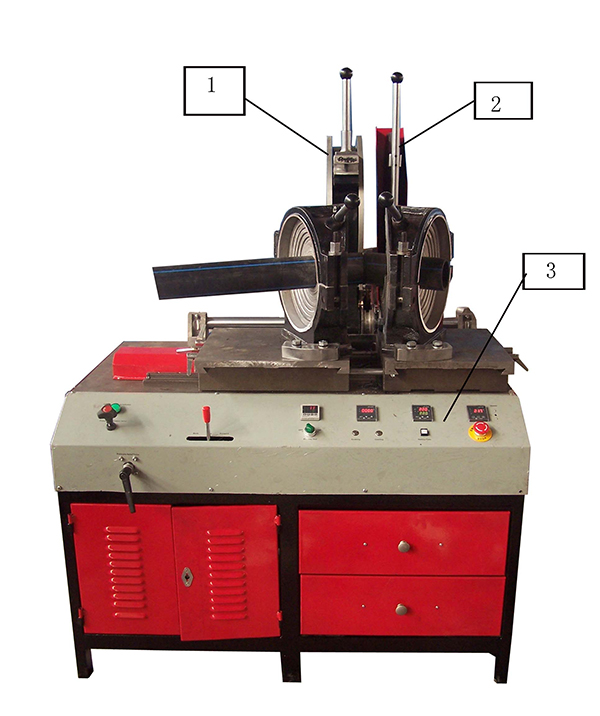

5.1 Main muchina

| 1. Kuronga chishandiso | 2. Kupisa ndiro | 3. Operation panel |

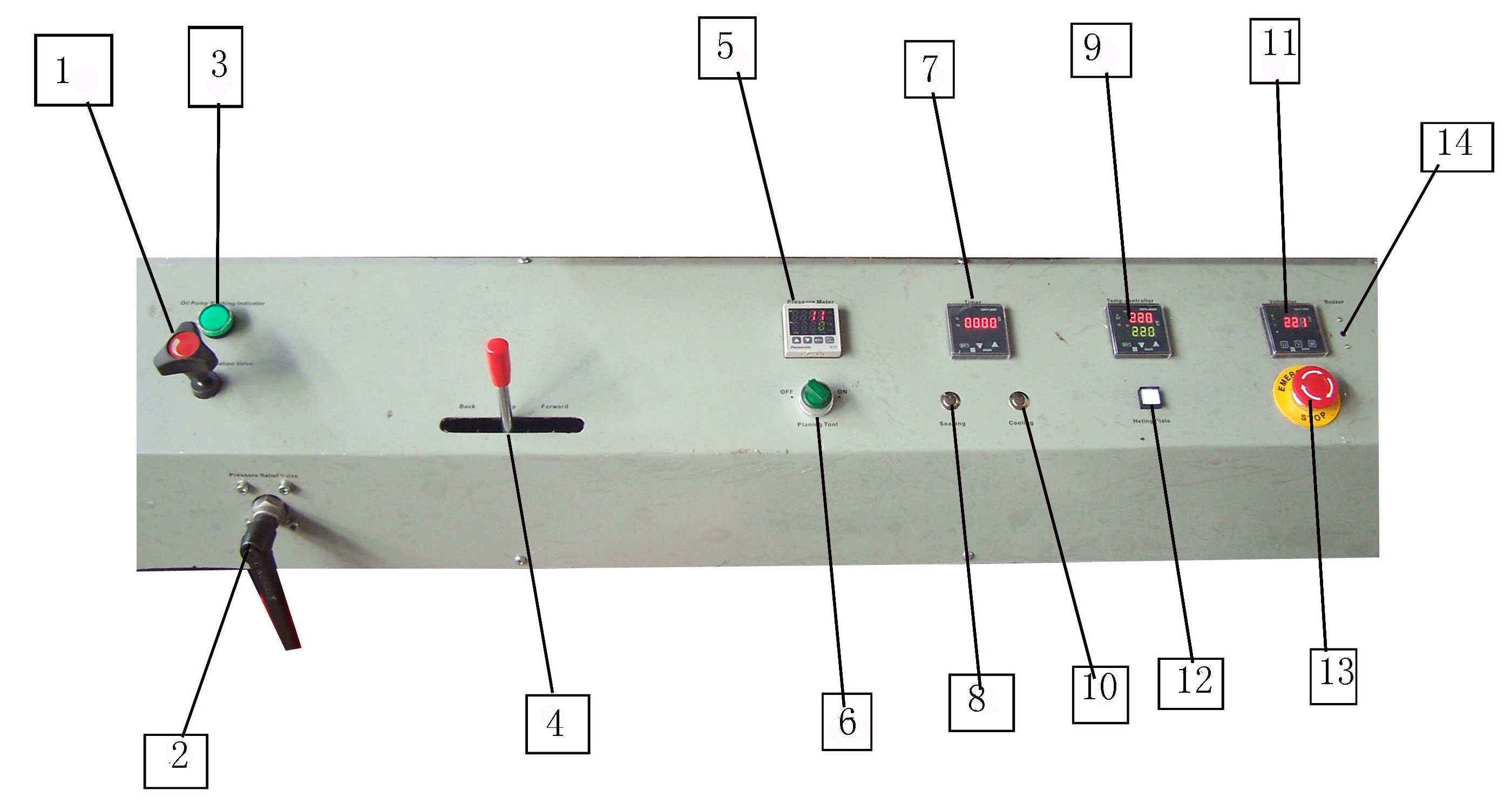

5.2 Operation panel

| 1. Pressure Regulation Valve | 2. Kufuridzira Relief Valve | 3. Oil Pump Working Indicator | 4. Direction Valve |

| 5. Digital Pressure Meter | 6. Kuronga Bhatani | 7. Timer | 8. Kunyura Nguva Bhatani |

| 9. Temperature Control Meter | 10. Kutonhodza Nguva Bhatani | 11. Voltmeter | 12. Heating Switch |

| 13. Emergency Stop | 14. Buzzer |

Installation

6.1 Kusimudza uye kuisa

Paunenge uchisimudza nekuisa muchina unofanirwa kuchengetwa wakachinjika, uye usamborerekera kana kudzosera kumashure kuti udzivise kukuvara kusingadiwe.

6.1.1 Kana forklift ikashandiswa, inofanirwa kuiswa nekungwarira kubva pasi pemuchina nekungwarira kudzivirira kukuvadza hose yemafuta uye dunhu.

6.1.2 Kana uchiendesa muchina kunzvimbo yekuisa, mainframe inofanirwa kuchengetedzwa yakatsiga uye yakachinjika.

6.1.3 Isai motokari kubhokisi rekudzikisa replaning tool uye yakagadziriswa nescrews, inoratidzwa muFig .3.

6.2 Kubatanidza

Ita shuwa kuti nzvimbo yacho yakakwana yekuisa muchina uye chengetedza muchina wese wakachinjika uye simbisa iko kubatanidzwa kwese masokisi, tambo uye hose kana uchiisa muchina.

6.2.1 Batanidza muchina mukuru kubhokisi remagetsi.

Fig. 4 Batanidza ndiro yekudziya kubhokisi remagetsi

Fig. 5 Batanidza mudziyo wekuronga kubhokisi remagetsi

6.2.2 Kubatanidza tambo yemuchina kune simba, izvo zvikamu zvitatu- waya shanu 380V 50HZ.

Kuti chengetedzo, muchina unofanirwa kuvharwa kubva pasi penzvimbo yemuchina.

6.2.3 Zadza iyo yakasefa hydraulic oiri. Kureba kwemafuta kunofanirwa kunge kuri 2/3 yehurefu hwehupamhi hweyeji yemukati.

Yambiro: Kuisa pasi kunofanirwa kupedzwa nevanhu vane hunyanzvi.

Murayiridzo Wekushandisa

Tevera mitemo yese yekuchengetedza pamushini. Munhu asina kudzidziswa haatenderwi kushandisa muchina.

7.1 Simba

Vhara chinokanganisa pasi

7.2 Kutanga pombi yemafuta

Tanga pombi yemafuta kuti utarise nzira inotenderera. Kana iyo geji yekumanikidza ine kuverenga, kutenderera kwacho, kana zvisiri, chinjana chero maviri mhenyu waya.

7.3 Tarisa uye gadzirisa kudhonza uye kufambisa kumhanya kwendiro yekukwevera. Kushanda kudzvinyirira kweiyo system ndeye 6 MPa. Ijoining pressure inogona kugadziriswa ne pressure regulation valve iri pane control panel. The planing pressure inofanira kuwedzerwa zvishoma nezvishoma, uye kuichengeta kana kuenderera mberi shavings kuoneka (kwete yakanyanya kukura). Kudya kumhanya kweplate yekukwevera kunogona kugadziriswa kuburikidza nevhavha yekutarisa (mukati mebhesi).

7.4 Clamps Kuiswa

Isa zvigaro zvekusungirira kuruboshwe nekurudyi (zvisungo zvematei kana magokora) zvinoenderana nezvinofanirwa kugadzirwa.

1) Gadzirisa ivo kutanga nepini yekukiya yakanamirwa nemushini;

2) Gadzirisa kona ine yakakosha nzvimbo mubato;

3) Simbisa siruu yekukiya nechipanera.

Kana simbi dzegokora dzichida kushandiswa, dzvanya zvakasimba nendiro yekukiya mushure mekugadzirisa kona.

7.5 Seta tembiricha yakatarwa pane tembiricha controller zvinoenderana nepombi welding process. (Ona chikamu 7.10)

7.6 Usati wasimudza kana kudzikisa mudziyo wekuronga vhura mudziyo wekukiya pamubato.

7.7 Mapombi anomira mumushini

7.7.1 Kupatsanura masimbi emuchina nekuita pane lever yedirection valve

7.7.2 Isai mapombi muzvisungiriro wozvisunga; nzvimbo iri pakati pemigumo yepombi mbiri inofanira kunge yakakwana yekuronga chishandiso.

7.7.3 Lock pressure relief valve, uchivhara migumo miviri, shandura vheji yekudzora kumanikidza kusvika iyo geji yekumanikidza inoratidza fusion pressure, iyo inotarirwa nemidziyo yepombi.

7.8 Kuronga

7.8.1 Kupatsanura mabhanhire nekuita pavharuvhu yekunangidzira uye yakavhurika zvizere vharafu yekuyamura.

7.8.2 Isa mudziyo weplaning pakati pemapombi maviri anogumira uye wobatidza, swedera kunoperera pombi yakananga kuchishandiso chekuronga nekuita pane inotungamira vharafu “mberi”, uye gadzirisa vharuvhu inodzora kumanikidza kuchengetedza kudzvanywa kwakakodzera kusvikira mashevha anoramba achionekwa kubva kune maviri. mativi.Cherechedza: 1) Ukobvu hwemashavings hunofanira kunge huri mukati me 0.2 ~ 0.5mm uye inogona kuchinjwa nekugadzirisa kureba kwechigadziro chekuronga.

2) Kuronga kudzvanywa hakufanirwe kudarika 2.0 MPa kudzivirira kukuvara kwechishandiso chekuronga.

7.8.3 Mushure mekuronga, patsanura zvisungo uye bvisa chishandiso chekuronga.

7.8.4 Vhara migumo miviri kuti uenzane. Kana iyo misalignment inopfuura 10% yehuputi hwepombi, ivandudze nekusunungura kana kuomesa zvisungo zvepamusoro. Kana gwanza riri pakati pemigumo richipfuura 10% yepombi yemadziro ukobvu, kuronga pombi zvakare kusvika wawana chinodiwa.

7.9 Welding

7.9.1 Seta nguva yekunyura uye nguva yekutonhodza zvinoenderana nemagadzirirwo ewelding.

7.9.2 Mushure mekubvisa mudziyo wekugadzira, isa ndiro yekudziya, Kiya zvishoma nezvishoma kumanikidza vharafu yekuyamura uchisundira kumberi vharafu, iyo inowedzera kupisa kupisa kune yakatsanangurwa fusion kudzvanywa.1). Iyo pombi inopera inonamira kune inopisa ndiro uye fusion inotanga.

7.9.3 Kana kabhinda kadiki kakaungana, sundidzira kumashure vharuvhu yekunanga iri pakati kuti ichengetedze kudzvanya. Shandura swing cheki vharafu kuti udzikise kudzvanywa kwekunyura kumanikidza (P2) wobva waikiya nekukasira. Wobva wadzvanya pasi bhatani renguva yekunyura kuenda kunguva.

7.9.4 Mushure mekunyura (maaramu e-buzzer), vhura machira nekuita pavharuvhu yekutungamira uye bvisa ndiro yekudziya nekukurumidza.

7.9.5 Batanidza migumo miviri yakanyunguduka nekukurumidza uye chengetedza vharafu yekutungamira pa "mberi" kwenguva pfupi uye wozosundira kumashure kunzvimbo yepakati kuti uchengetedze kumanikidza. Panguva ino, kuverenga mukudzvinyirira gauge ndiyo yakagadziriswa fusion pressure (kana zvisingaiti, igadzirise nekuita pavhavha yekudzivirira).

7.9.6 Dzvanya pasi bhatani renguva yekutonhodza kana kutonhora kunotanga. Mushure mekunge nguva yekutonhora yapfuura, iyo buzzer alarm. Relive the system pressure nekuita pa pressure relief valve, vhura ma clamps uye bvisa majoini.

7.9.7 Tarisa chibatanidza maererano newelding process standards.

7.10 Tembiricha controller uye timer

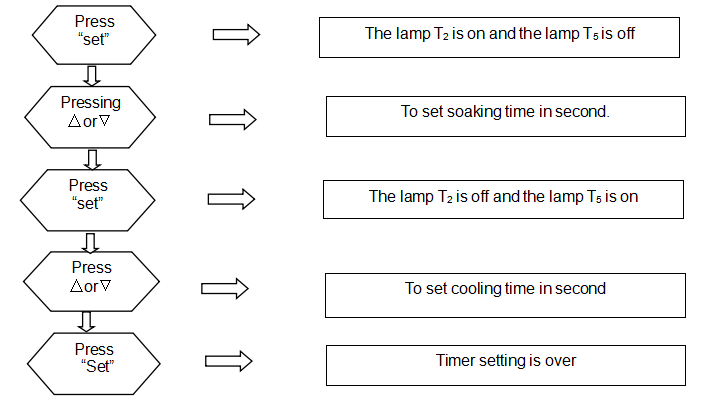

7.10.1 Kuisa nguva

7.10 Tembiricha controller uye timer

7.10.1 Kuisa nguva

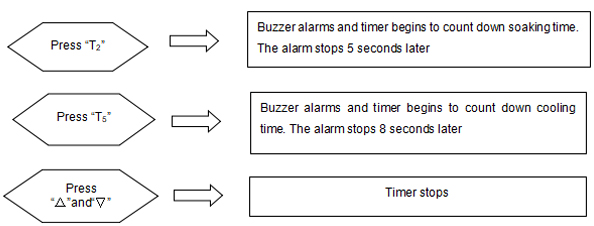

7.10.2 Timer kushandisa

7.10.3 Temperature controller setting

1) Dzvanya "SET" kweanopfuura masekonzi matatu kusvika "sd" yaratidzwa pahwindo rekumusoro

2) Dzvanya "∧" kana "∨" kuti uchinje kukosha kune yakatarwa tembiricha (dzvanya "∧" kana "∨" uchienderera, kukosha kuchawedzera kana kubvisa otomatiki)

3) Mushure mekuseta, tinya "SET" kuti udzokere kukutarisa uye kutonga interface

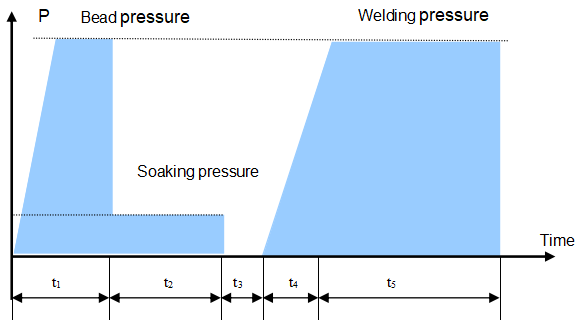

Reference Welding Standard (DVS2207-1-1995)

8.1 Nekuda kweakasiyana welding zviyero uye PE zvinhu, iyo nguva uye kumanikidzwa kwechikamu che fusion process zvakasiyana. Zvinoratidza kuti t iye chaiwo welding maparameter anofanirwa kuratidzwa nemapombi uye mafittings anogadzira

8.2 Yakapihwa welding tembiricha yepombi dzakagadzirwa kubva PE, PP uye PVDF neDVS chiyero siyana kubva180 ℃ kusvika 270 ℃. Kushanda tembiricha yekudziya ndiro iri mukati me180~230℃, uye yayo Max. pamusoro tembiricha inogona kusvika 270 ℃.

8.3 Reference standardDVS2207-1-1995

| Kukora kwemadziro (mm) | Bead urefu (mm) | Bead kuvaka-up pressure (MPa) | Kunyura nguva t2(Sekondi) | Kunyura pressure (MPa) | Kuchinja-nekufamba kwenguva t3(sekondi) | Pressure kuvaka-up nguva t4(sekondi) | Welding pressure (MPa) | Nguva yekutonhodza t5(min) |

| 0~4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45~70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7~12 | 1.5 | 0.15 | 70~120 | ≤0.02 | 6~8 | 6~8 | 0.15±0.01 | 10~16 |

| 12~19 | 2.0 | 0.15 | 120~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16~24 |

| 19~26 | 2.5 | 0.15 | 190 -260 | ≤0.02 | 10~12 | 11~14 | 0.15±0.01 | 24~32 |

| 26~37 | 3.0 | 0.15 | 260~370 | ≤0.02 | 12~16 | 14~19 | 0.15±0.01 | 32~45 |

| 37~50 | 3.5 | 0.15 | 370~500 | ≤0.02 | 16~20 | 19~25 | 0.15±0.01 | 45~60 |

| 50~70 | 4.0 | 0.15 | 500~700 | ≤0.02 | 20~25 | 25~35 | 0.15±0.01 | 60~80 |

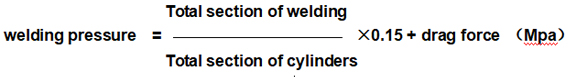

Ongorora: Bead kuvaka-up kumanikidza uye welding kudzvanywa mufomu ndiyo inokurudzirwa interface yekumanikidza, iyo geji yekumanikidza inofanirwa kuverengerwa neinotevera formula.

Nzira Yekugadzirisa Kugadziriswa

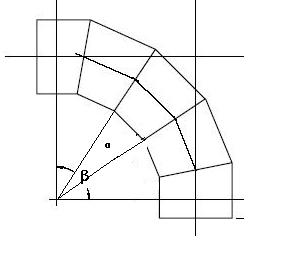

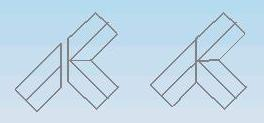

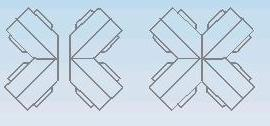

9.1 Kugadzira gokora

9.1.1 Zvichienderana nekona yegokora uye uwandu hwezvikamu zvewelding, kona yewelding pakati penhengo imwe neimwe inogona kusarudzwa.

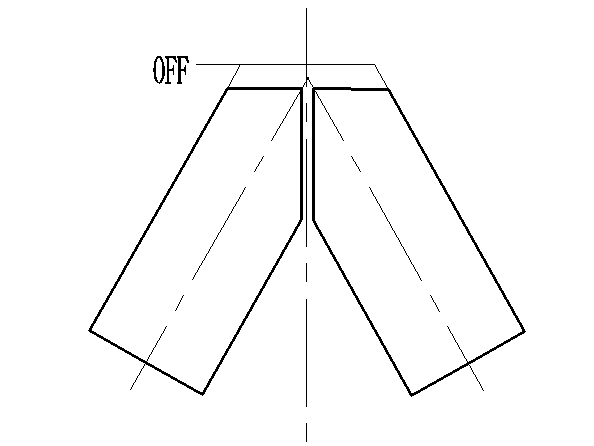

Tsanangudzo: α - welding angle

β - kona yegokora

n - huwandu hwezvikamu

Semuenzaniso: 90 ° gokora rakakamurwa kuita zvikamu zvishanu kuti zvipiswe, iyo welding angle α=β/(n-1)=90°/(5-1)=22.5°

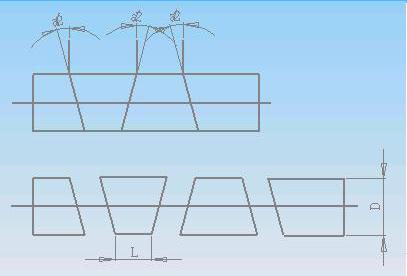

9.1.2 Min dimension yechikamu chega chega chewelding muzvikamu zvewelding chinochekwa nebhendi resaha zvichienderana nekona.

Tsanangudzo:

D - kunze kwedhayamita yepombi

L - Min kureba kwese chikamu

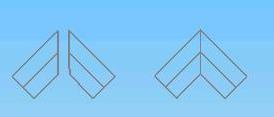

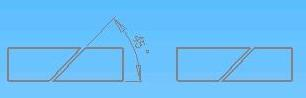

9.2 Maitiro ekugadzira ma tee

9.2.1 Zvishandiso zvakaita sedhiyagiramu inotevera:

9.2.2 Welding sechimiro chedhiyagiramu:

9.2.3 Kona inochekwa sedhiyagiramu

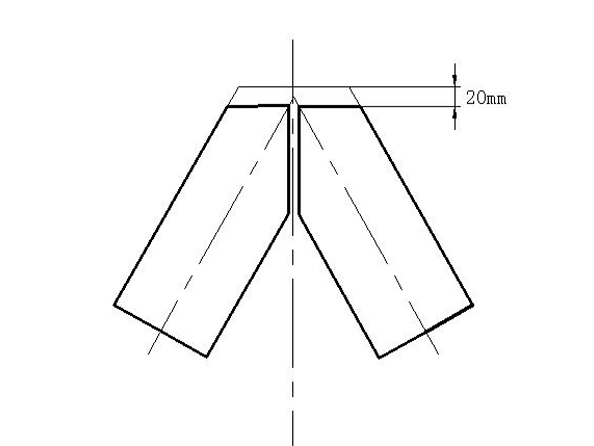

Ziviso: Dimension "a" haifanire kunge iri pasi pemakumi maviri㎜ inova seyekuronga margin uye kubhadharira bhedhi rinonyungudika.

9.2.4 Welding sechimiro chedhiyagiramu, ma tee akagadzirwa.

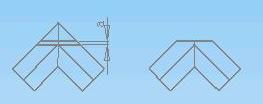

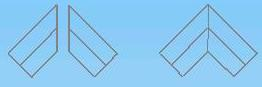

9.3 Maitiro ekuenzana dhayamita emuchinjikwa mapaipi akagadzirwa

9.3.1 Zvishandiso zvinochekwa sedhayagiramu inotevera

9.3.2 Iwo maviri maviri akasungwa akasungwa sechimiro chedhiyagiramu:

9.3.3 Kona inochekwa sedhiyagiramu:

Cherechedza: Dimension "a" haifanire kunge iri pasi pemakumi maviri㎜,Iyo iri kuronga margin uye kubhadharira bhedhi rinonyungudika.

9.3.4 Welded sechimiro chedhiyagiramu.

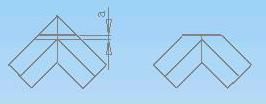

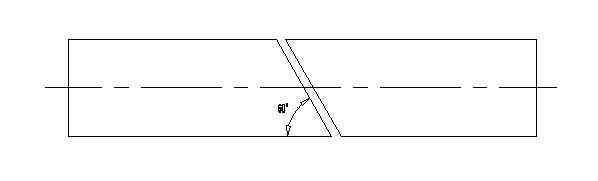

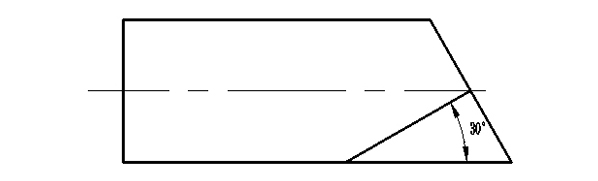

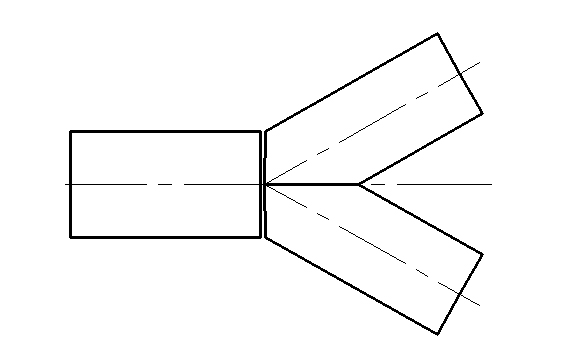

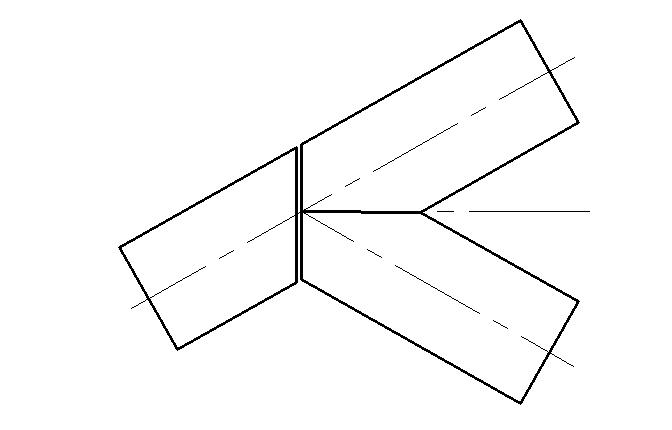

9.4 Maitiro ekugadzira "Y" chimiro chekugadzira (45 ° kana 60 °)

9.4.1 cheka semuenzaniso unotevera (tora 60 ° "Y" zvimiro zvechimiro semuenzaniso)

9.4.2 Enderera kune yekutanga welding semadhirowa anotevera:

9.4.3 Gadzirisa masimbi uye enda kune yechipiri welding.

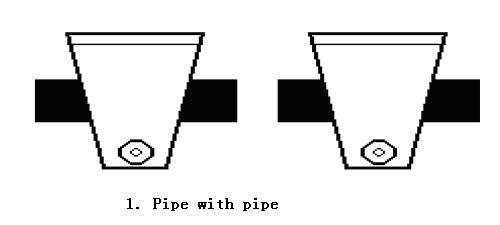

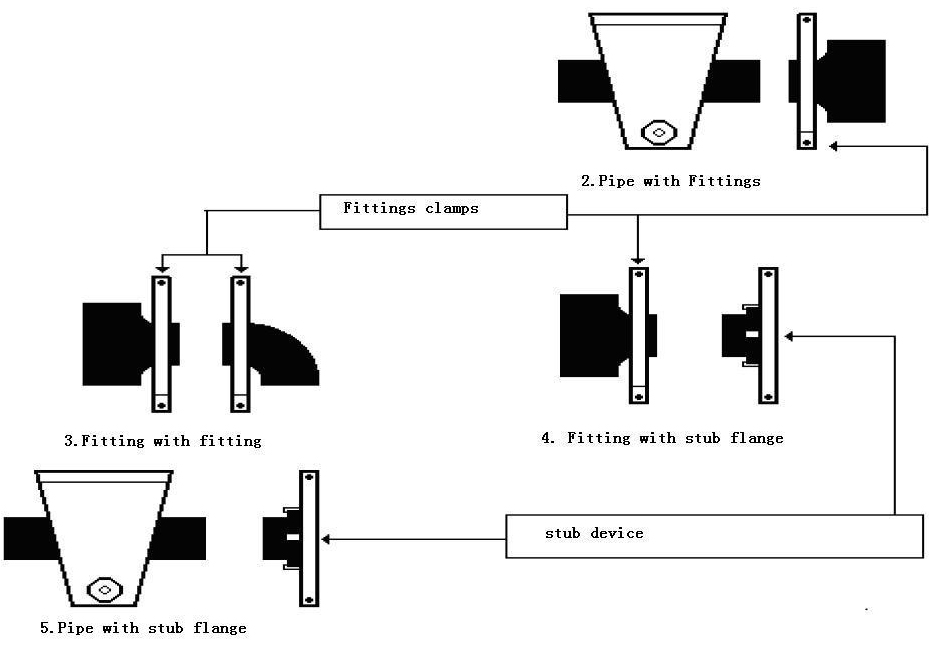

9.5 mamwe mafittings welding

9.5.1. Pipe nenyere

9.5.2. Pipe nekuisa

9.5.3 Kukodzera nekuisa

9.5.4 Kuisa ne stub flange

9.5.5 Pipe ine stub flange

Malfunctions Analyzing And Solutions

10.1 Anowanzo sangana matambudziko emhando yekuongorora:

10.2 Kuchengetedza

iwe PTFE yakavharwa kupisa ndiro

Ndokumbira utarise kubata girazi rekudziya kuitira kuti udzivise kukanganisa kune PTFE coating.

Chengetedza nguva dzose yakachena PTFE yakavharwa nzvimbo, kuchenesa kunofanira kuitwa nepamusoro ichiri kudziya nekushandisa jira rakapfava kana bepa, kudzivirira zvinhu zvinoputika zvinogona kukanganisa PTFE yakavharwa nzvimbo.

Nguva nenguva, tinokupa zano:

- Chenesa nzvimbo nekushandisa chinokurumidza evaporation detergent (doro)

- Tarisa kusimba kwezvikwiriso uye tambo uye plug mamiriro

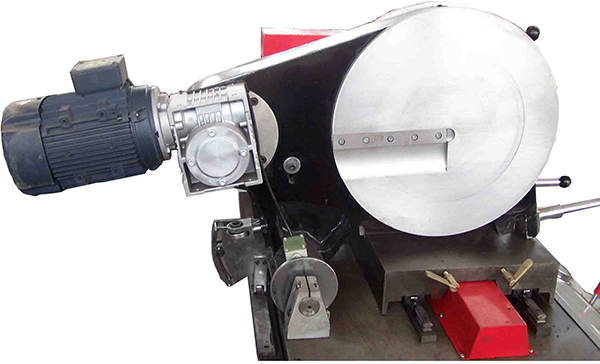

u Kuronga chishandiso

Zvinokurudzirwa kuti ugare wakachena mashizha uye kugeza mapulley nekushandisa detergent.

Panguva dzenguva dzose ita basa rekuchenesa rakakwana rine lubrication yemukati zvakare

u Hydraulic unit

Iyo hydraulic unit haidi kutariswa kwakasiyana zvakadaro mirairo inotevera inofanirwa kuteverwa:

a. Tarisa nguva nenguva mafuta akachinjika uye kana ukawedzera nemhando yemafuta:

Iyo yakachinjika haifanirwe kuve yakaderera kupfuura masendimita mashanu kubva patangi repamusoro rakachinjika.

Kuongorora mazuva ese e15 ekushanda kunokurudzirwa zvakanyanya.

b. Tsiva mafuta zvachose mwedzi mitanhatu yega yega kana mushure memaawa mazana matanhatu nemakumi matatu ekushanda.

c. Chengetedza wakachena iyo hydraulic unit nehanya zvakanyanya patangi uye nekukurumidza makubatanidza.

10.3 Kakawanda kusashanda ongororo uye mhinduro

Panguva yekushandiswa, hydraulic unit uye magetsi mayuniti anogona kuoneka mamwe matambudziko. Kakawanda kusashanda zvakanaka kwakanyorwa sezvinotevera:

Ndapota shandisa maturusi akabatanidzwa, maspare parts kana mamwe maturusi ane chitupa chekuchengetedza uchichengeta kana kutsiva zvikamu. Zvishandiso uye zvikamu zvakasara zvisina chitupa chekuchengetedza zvinorambidzwa kushandiswa.

| Kusashanda zvakanaka kwehydraulic unit | |||||

| No | kusashanda zvakanaka | anoongorora | mhinduro | ||

| 1 | Iyo mota haishande |

yasunungurwa

| |||

| 2 | Iyo mota inotenderera zvishoma nezvishoma ine ruzha rusingaite |

| kupfuura 3 MPa

| ||

| 3 | Silinda inoshanda zvisina kujairika |

yakavharwa zvakasimba

| kubuda mhepo. | ||

| 4 | Kukweva ndiro inofambisa silinda haishande |

vharafu yakavharwa |

vharafu yekuyerera (1.5 MPa yakakodzera).

| ||

| 5 | Cylinder leak | 1. Mhete yemafuta inokanganisa2. Silinda kana piston yakuvadzwa zvakaipa | 1. Tsiva mhete yemafuta2. Dzorera humburumbira | ||

| 6 | Dzvinyiriro haigone kuwedzerwa kana kuchinjika kwakakurisa | 1. Nheyo yevharuvhu yekuyerera yakavharwa.2. Pombi yadeuka.3. The joint slack yepombi yakasunungurwa kana key groove is skid. | 1. Chenesa kana kutsiva coreof over-flow valve2. Tsiva pombi yemafuta3. Tsiva mubatanidzwa slack | ||

| 7 | Kucheka kudzvinyirira hakugone kugadziriswa | 1. Dunhu rine mhosva2. Electromagnetic coil inokanganisa3. The overflow valve yakavharwa4. Kucheka vharafu yekuyerera hakuna kujairika | 1. Tarisa dunhu (iyo diodein tsvuku iyo electromagnetic coil inopenya)2. Tsiva iyo electromagnetic coil3. Chenesa musimboti wevharuvhu yekuyerera4. Tarisa kutema pamusoro-kuyerera kwevhavha | ||

| Kutadza kushanda kwemagetsi emagetsi | |||||

| 8 | Muchina wese haushande |

| 1. Tarisa tambo yemagetsi2. Tarisa simba rekushanda3. Vhura pasi fault interrupter | ||

| 9 | Ground fault switch nzendo |

| 1. Tarisa tambo dzemagetsi2. Tarisa zvinhu zvemagetsi.3. Tarisa iyo yepamusoro-kumusoro powersafety mudziyo | ||

| 10 | Kuwedzera tembiricha zvisina kujairika |

4. 4. Kuverengwa kwetembiricha yekushisa kunopfuura 300 ℃, zvinoreva kuti sensor inogona kukuvara kana kubatana kwakasununguka. Kana iyo tembiricha controller inoratidza LL, izvo zvinoratidza kuti sensor ine pfupi dunhu. Kana iyo tembiricha controller inoratidza HH, iyo inoratidza kuti dunhu re sensor rakavhurika. 5. Gadzirisa tembiricha nebhatani riri pane tembiricha controller.

| contactors

controller

isa tembiricha

contactors kana zvichidiwa | ||

| 11 | Kutadza kuzvidzora pakupisa | Chiedza chitsvuku chinopenya, asi tembiricha ichiri kukwira, imhaka yekuti chinongedzo chakanganisa kana majoini 7 ne8 haagone kuvhura kana awana tembiricha inodiwa. | Tsiva tembiricha controller | ||

| 12 | Planning tool haitenderere | Iyo yekumisikidza switch haishande kana mekiniki zvikamu zveplaning tool zvakatemwa. | Tsiva muganhu wezvishandiso zvekuronga chinja kana diki sprocket | ||

Circuit & Hydraulic Unit Diagram

11.1 Circuit unit diagram (inoonekwa muapendikisi)

11.2 Hydraulic unit diagram (inoonekwa mune appendix)

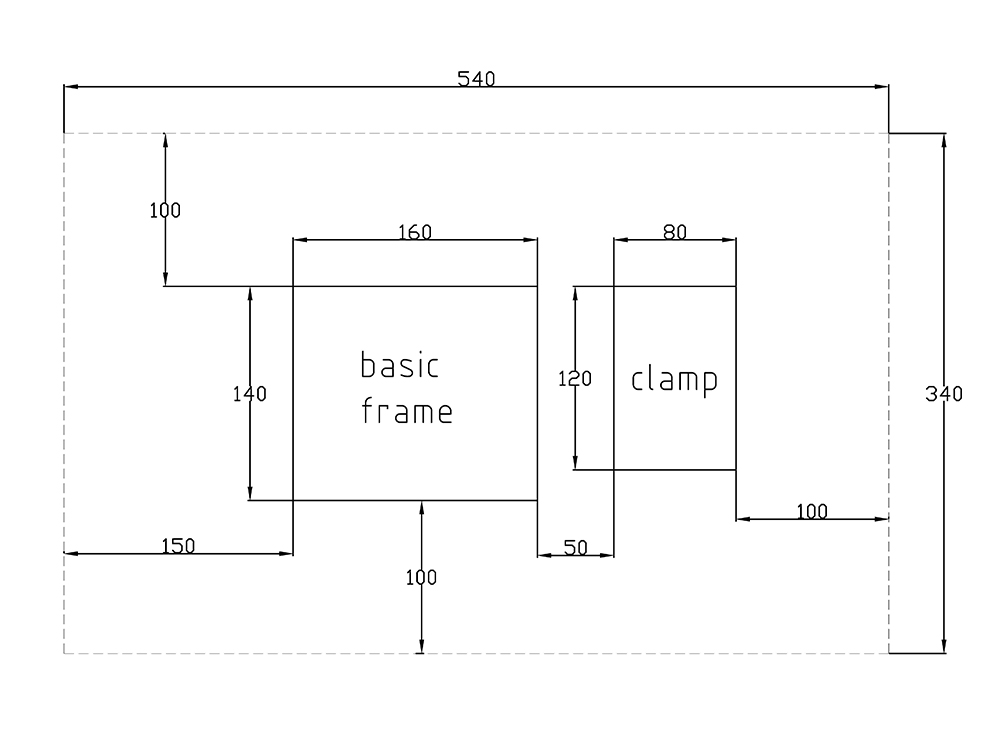

Space Occupation Chati