TPWC315 BAND SAW OPERATION Manual

Tsanangudzo Yakakosha

Asati ashandisa muchina, chero munhu anofanirwa kuverenga tsananguro iyi nekuchenjerera uye kuichengeta zvakanaka kuti ave nechokwadi chekuchengetedzwa kwemidziyo uye kuchengetedzwa kwemushandisi, pamwe nekuchengetedzwa kwevamwe.

2.1 Muchina uyu unoshandiswa kucheka pombi dzakagadzirwa kubva kuPE, PP nePVDF uye haugone kushandiswa kucheka zvinhu zvisina-tsananguro; kana zvisina kudaro muchina unogona kukuvara kana kuguma netsaona.

2.2 Usashandise muchina uri panzvimbo ine njodzi inogona kuputika

2.3 Muchina uyu unofanirwa kushandiswa nevashandi vane mutoro, vane hunyanzvi uye vakadzidziswa.

2.4Muchina unofanirwa kushandirwa panzvimbo yakaoma. Matanho ekudzivirira anofanira kutorwa kana ashandiswa mumvura inonaya kana pavhu rakanyorova.

2.5 Simba rekuisa riri mukati me380V±10%, 50Hz. Kana mutsara wekupinda wakawedzerwa wakashandiswa, mutsara unofanirwa kuva nechikamu chekutungamira chakakwana.

2.6 Zadza hydraulic mafuta (N46 ISO3448) mutangi isati yatanga kushandisa. Huwandu hwemafuta hunofanirwa kunge huri 2/3 yetangi.

Safety

Mavara anotevera anonamirwa pamushini.

3.2. Chengetedzo Yekuchengetedza

Paunenge uchishanda muchina, mirairo uye mitemo yekuchengetedza inofanirwa kuteedzerwa nemazvo.

3.2.1 Mushandisi anofanira kunge akadzidziswa uye ane hunyanzvi vashandi.

3.2.2 Nyatsoongorora uye chengetedza muchina pagore kuitira kuchengetedza uye kuvimbika kwemuchina.

3.2.3 Simba: bhokisi rekugovera magetsi rinofanira kunge riine chinovhiringidza pasi chine chiyero chekuchengetedza magetsi.

Earthing: Iyo saiti yese inofanirwa kugovera imwechete pasi waya uye iyo yekubatanidza pasi system inofanirwa kupedzwa uye kuedzwa nevanhu vane hunyanzvi.

3.2.4 Kuchengeta kwemuchina:

Kune iyo min njodzi zvishandiso zvese zvinofanirwa kushanda sezvinotevera:

※ Usabate electrophorus zvikamu

※ Rambidza kudhonza kubva patambo kuti ubvise

※ Usaise chinhu chinorema kana chakapinza patambo, uye kudzora tembiricha yetambo mukati mekudzikamisa tembiricha (70 ℃)

※ Usashande munzvimbo ine mvura. Tarisa kana groove neshangu zvaoma.

※ Usasasa muchina

3.2.5 Tarisa mamiriro ekudzivirira emuchina nguva nenguva

※ Tarisa kuvharwa kwetambo kunyanya mapoinzi akawedzerwa

※ Usashandise muchina uri pasi pemamiriro akanyanya.

※ Tarisa kana iyo yepasi kukanganisa kukanganisa inoshanda zvakanaka kanenge pamwedzi.

※ Tarisa pasi pemuchina nevashandi vanokwanisa

3.2.6 Geza muchina nemazvo

※ Usashandise zvinhu zvinokuvadza kuvharisa zviri nyore (segasi, abrasive, uye zvimwe zvinonyungudutsa)

※ Simba rinofanira kubviswa kana wapedza basa.

Kana kungotevera zvataurwa pamusoro apa, kungwarira kunogona kushanda zvakanaka.

3.2.7EMERGENCY MIRA

Chero mamiriro asingatarisirwe anoitika, ndapota dzvanya "EMERGENCY MIRA" nekukasira kumisa muchina. Mushure mekugadzirisa matambudziko shandura EMERGENCY STOP newachi kuti utange muchina zvakare.

3.2.8 Kusimba kwezvikamu:Tarisa kana mapaipi akagadziriswa nemazvo uye zvakasimba. Ita shuwa kuti haikwanise kutsvedza pasi kune anokuvadza anoshanda

3.2.9 Vashandikuchengeteka paunenge uchishanda

Bvisa zvishongo nemhete, uye usapfeke hembe dzisina kusimba dzivisa kupfeka tambo dzeshangu, ndebvu refu kana bvudzi refu rinogona kusungirirwa mumushini.

3.2.10Chengetedza nzvimbo yacho yakachena uye yakachenay

Mhomho, yakasviba uye ine mussy saiti haina kunaka kushanda, saka zvakakosha kuchengetedza saiti yakachena uye yakatsvinda.

3.2.11 Munhu asina kudzidziswa haafanire kubvumidzwa kushandisa muchina chero nguva.

3.3 Njodzi Dzingangoitika

3.3.1 Band saw

Muchina uyu unongoshandiswa nemunhu ane hunyanzvi kana kuti akadzidzira basa, zvikasadaro tsaona isingadikanwi ingangokonzerwa.

3.3.2 Chipenga

Usambofa wakabata blade inomhanya, kana kukuvara kunogona kukonzera

3.3.3 Kucheka

Usati wacheka, chenesa jecha kunze kwepombi kana imwe dhizaini yakarira mumapombi paunenge uchitakura. Izvi zvinogona kudzivirira kukuvara kusingadiwe kwesaha kana dzimwe tsaona

Inoshanda Range Uye Unyanzvi Parameter

| Type | TPWC-315 |

| Zvishandiso zvekucheka | PE, PP, PVDF |

| Max. Kucheka kugona | 315mm |

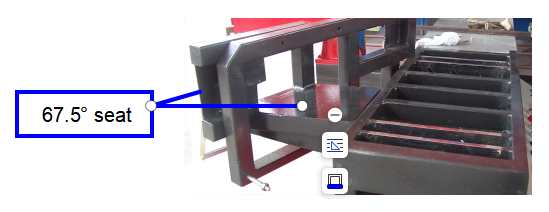

| Kucheka kona | 0°~67.5° |

| Kusarurama kwekona | ≤1° |

| Line velocity yesaha blade | 230 m/min |

| Kupisa kwenzvimbo | -5~45℃ |

| Magetsi | ~380 V±10 % |

| Frequency | 50 Hz |

| Total current | 5A |

| Total power | 3.7 KW |

| Kutyaira Motor | 2.2 KW |

| Hydraulic unit mota | 1.5 KW |

| Insulation resistance | >1MΩ |

| Max. hydraulic pressure | 6 MPa |

| Huremu hwese (kg) | 1100 |

Tsanangudzo

Iyo bhendi saha inogona kushandiswa kucheka mapombi ePE zvinoenderana nekuseta kona paunenge uchigadzira gokora, tee uye kuyambuka, kuitira kuti muchina uve nemaitiro ekushanda kwepamusoro uye chiyero chekushandisa kwezvinhu.

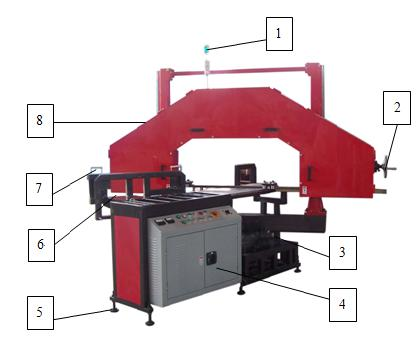

5.1 Tsanangudzo yezvikamu

| 1. yambiro mudziyo | 2. tension vhiri | 3.angle scale | 4. control box |

| 5. level adjustor | 6. 67.5° chigaro | 7. gadzirisa mudziyo | 8.saw box |

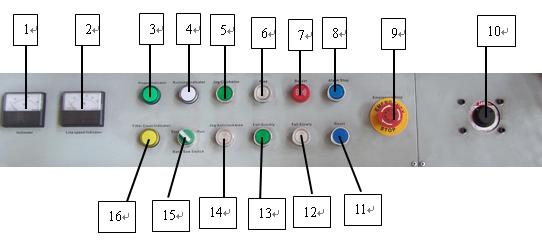

5.2 Operation panel

| 1. Voltmeter | 2. Line Speed Indicator | 3. chiratidzo chesimba | 4. Chiratidzo chekumhanya |

| 5. Jog wakatarisa wachi | 6. Simuka | 7. Buzzer | 8. Alarm stop |

| 9. Emergency stop | 10.Feed speed adjustor | 11. Reset | 12. Kudonha zvishoma nezvishoma |

| 13. Kuwa nekukurumidza | 14. jog anti clockwise | 15. Band saw switch | 16. mafuta pombi kushanda chiratidzo |

Installation

6.1 Kusimudza uye kuisa

6.1.1 Kana forklift ikashandiswa paunenge uchiisa, isa foloko nekungwarira kubva pasi pemuchina kudzivirira kukuvadza hose yemafuta kana dunhu.

6.1.2 Pakuisa muchina, muchina unofanirwa kuchengetedzwa wakatsiga uye nhanho nekugadzirisa nhanho inogadzirisa.

6.1.3 Muchina uyu wakajairika unogona kucheka kona 0 ~ 67.5 °, kana kona iri mukati me45 ° ichidikanwa, chigaro che67.5 ° chinofanira kubviswa chisati chashanda.

Operation

7.1 Kutanga

7.1.1 Simba muchina, uye chiratidzo chesimba chinofanira kunge chiri (kana chisipo, kubatana kwakashata).

7.2 Kuyedzwa kwebhokisi remasaha richikwira nekudzika nekutenderedza feed kasidhijita kurudyi rwepaneru yekushandisa.

7.3 Dzvanya bhatani rekuti “jog clockwise” uye “jog anticlockwise” kuti utarise kwainomhanya blade yesaha. Kana ichitenderera ichienda kwakashata, chinjana chinongedzo pakati pewaya mbiri mhenyu dzakabatanidzwa kune magetsi.

7.4Kucheka kushanda

7.4.1 Sunungura siruu yekukiya kona, sundidzira bhokisi resaha nemaoko kuenda kukona inodiwa (maererano nekona inodiwa), uye sunga siruu yekukiya kona.

7.4.2 Simudza bhokisi resaha kusvika kureba (kunotemwa nedhayamita yepombi ichachekwa) kuona kuti zino resaha riri pamusoro pepombi.

7.4.3 Isa tubing yekucheka patafura yebasa, gadzirisa nzvimbo yekucheka, uye gadzirisa pombi nebhanhire renylon nekuvhara mudziyo.

7.4.4 Tanga blade yesaha, kana blade yesaha ikawana kumhanya kwakatemwa (Running indicator ichapenya), shandura feed speed adjustor kudonha bhokisi resaha zvishoma nezvishoma. Iko kumhanya kwekudonha kunofanirwa kudzorwa zvinoenderana nedhayamita yepombi uye ukobvu.

7.4.5 Kana kuchekwa kwave kupera, ndapota bata pombi yakachekwa kuti isavhare blade yesaha.

7.4.6 Dzvanya bhatani rechimbichimbi kana paine kusanzwisisika kukaitika panguva yekucheka. Mushure mekugadzirisa matambudziko shandura EMERGENCY STOP newachi kuti utange muchina zvakare..

7.4.7 Saw blade inomira yega kana yasvika panzvimbo yakaderera

7.4. 8 Kana wapedza kucheka Bvisa pombi yakachekwa wochekazve.

7.4. 9 Muchina uyu wakajairwa unogona kucheka kona 0 ~ 67.5 °, kana kona iri mukati me45 ° ichidikanwa, chigaro che67.5 ° chinofanira kubviswa chisati chashanda pamapombi, chinoratidzwa sezvizvi:

Yambiro:

1) Simba muchina zvakare mumaminetsi makumi matatu mushure mekucheka simba rekudzivirira chinoshandura.

2) Muchina wese unofanirwa kuve wakaiswa pasi kuti uve nechokwadi chekuchengetedza

3) Cheki uye kuchengetedza kwezvikamu zvemagetsi zvinofanira kuitwa nemunhu ane unyanzvi

Mhosva uye Solutions

Ndapota shandisa maturusi akabatanidzwa, maspare parts kana mamwe maturusi ane chitupa chekuchengetedza uchichengeta kana kutsiva zvikamu. Zvishandiso uye zvikamu zvakasara zvisina chitupa chekuchengetedza zvinorambidzwa kushandiswa.

Tafura.1 Mechanical kukundikana

| Item | Tsanangudzo | Analysis | Solutions |

| 1 | Band saw blade iri jammed | 1. Iko kona yechigaro che rotary haina kuvharwa zvakasimba. 2. Band saw blade haina tensioned zvakasimba. 3. Saha rinomhanya zvishoma nezvishoma kana kuti saha rinodonha nekukurumidza | 1. Shingairira kona yekuvhara mudziyo. 2. Dzora tension roller kuti isimbise bhendi resaha. 3. Dzikisa kukurumidza kudonha uye gadzirisa yakakwirira mutsara wevheji yesaha blade. |

| 2 | Band saw blade madonhwe | 1. Saw blade holders haina kugadziriswa zvakanaka. 2. Band saw blade haina tensioned. 3. Saw blade vhiri rakasunungurwa. 4. Nheyo yevhavha yekuyerera yakavharwa | 1. Gadzirisa chibatiso chesaha kuti ugadzirise bhendi resaha munzvimbo yakanaka. 2. Rongedza tension roller kuti isimbise bhendi resaha. 3. Sunga vhiri resaha zvakasimba. 4. chenesa musimboti wevhavha yekufashukira |

Tafura.2 Hydraulic system kukanganisa

| Item | Tsanangudzo | Zvinokonzera | Solutions |

| 1 | Iyo mota yepombi yemafuta haishande | 1. Contactor haina kuvharwa 2. Mitsetse yemukati inodimburwa 3. Motokari inokanganisa. | 1. Tarisa contactor; 2. Tarisa kubatana kana plug. 3. Ongorora uye gadzirisa injini. |

| 2 | Hapana kumanikidzwa muhurongwa, uye ruzha rukuru mupombi | 1. Kutenderera kutungamira kwepombi yemafuta haina kunaka; 2. Coupler yemota uye pombi yemafuta yakabviswa 3. Mafuta haana kukwana kana kusvibiswa zvakanyanya. | 1. Inofanira kutenderera inopesana newachi; 2. Tarisa coupler; 3. Zadza kana kuchinja mafuta; |

| 3 | Kusimudza kumhanya kwe silinda huru inokurumidza kana kunonoka | 1. Kudzvanywa kwehurongwa kwakanyanya kana kuderera; 2. Throttle valve inogadziriswa zvisina kunaka; 3. Controllable cheek valve inogadziriswa zvisina kunaka. | 1. Rongedza kudzvanywa kwehurongwa; 2. Gadzirisa throttle valve; 3. Gadzirisa vharuvhu yenzira imwe chete. |

| 4 | Dzvinyiriro haigone kugadziridzwa kusvika pakakwirira kana kuti pressure fluctuation yakakurisa | 1. The overflow valve core yakavharwa 2. Sefa yemafuta yakavharwa. 3. Kufashukira valve core yakavharwa | 1. Dimbura & geza kana shandura vharafu yekufashukira 2. Geza sefa yemafuta. 3 .Disassemble uye uchenese iyo overflow valve core. |

Circuit & Hydraulic Unit Diagram

9.1 Circuit unit diagram (Reference to appendix)

9.2 Hydraulic unit diagram (Reference to appendix)