TPW200 BUTT FUSION MACHINE OPERATION Manual

Inoshanda Range Uye Unyanzvi Parameter

| Type | TPWS200 |

| Zvishandiso | PE, PP uye PVDF |

| Range yedhayamita × ukobvu | 200mm × 11.76mm |

| Ambient temp. | -5~45℃ |

| Magetsi | 220V±10%, 60Hz |

| Total current | 12A |

| Total power | 2.0 KW |

| Kusanganisira: Heating plate | 1.2 KW |

| Planning tool | 0.8 KW |

| Max. Tembiricha | <270℃ |

| Kusiyana kwekushisa kwepamusoro kweplate yekupisa | ± 5℃ |

| Max. fusion pressure | 1040N |

| Huremu hwese (kg) | 35KG |

Nhanganyaya YeMuchina

Muchina uyu une basic frame, kupisa ndiro, kuronga chishandiso uye rutsigiro.

Murayiridzo Wekushandisa

5.1 Midziyo yese inofanirwa kuiswa pane yakatsiga uye yakaoma ndege kuti ishande.

5.2 Usati wavhiya ita shuwa zvinhu zvinotevera:

Iyo magetsi emagetsi ndiyo yakatsanangurwa zvinoenderana nebutt fusion muchina

Tambo yemagetsi haina kuputswa kana kusakara

Mashizha emudziyo wekuronga akapinza

Zviridzwa zvese zvakajairika

Zvose zvinodiwa zvikamu uye zvishandiso zviripo

Muchina uyu uri mumamiriro akanaka

5.3 Isa zviiswa zvakakodzera zvinoenderana nekunze kwedhayamita yepombi/fitting

5.4 Welding maitiro

5.4.1. Usati wapinza, chokutanga, tarisa kana pane zvikwambo kana mafisuro pamusoro pepombi/fittings. Kana kudzika kwekukwenya kana kutsemuka kuchipfuura 10% yemadziro emadziro, bvisa mavanga kana mafisu.

5.4.2 Geza mukati nekunze pamusoro pepombi inoperera kuti isimbiswe.

5.4.3 Isai mapaipi/mafittings uye chengetai kureba kwepombi/mafittings anoperera kuti ave welded aenzane (sepfupi sezvinobvira). Imwe mugumo wepombi inofanira kutsigirwa nema rollers kuderedza kupesana. Sungai zvisungo zvezvisungo kugadzirisa mapaipi/mafittings.

5.4.4 Isa mudziyo wekuronga, wochibatidza uye wovhara pombi/zvinogumira nekushandisa tsvimbo mbiri dzemutyairi uchitarisana nechishandiso chekuronga kusvikira mashevha anoramba achienderera uye akafanana aonekwa kubva kumativi ese. Kuparadzanisa furemu, dzima chishandiso chekuronga uye ubvise. Ukobvu hwemashavings hunofanira kunge huri mukati me 0.2 ~ 0.5 mm uye inogona kugadziriswa nekugadzirisa kureba kwemashizha ekugadzirisa.

6.4.5 Vhara mapaipi/fitting magumo uye tarisa kurongeka. Iyo misalignment haifanire kudarika 10% yehukobvu hwemadziro, uye inogona kuvandudzwa nekusunungura kana kuomesa screws ye clamps. Mukaha pakati pemigumo yepombi mbiri haifanire kudarika 10% yemadziro emadziro; kana zvisina kudaro mapaipi / zvigadziri zvinofanira kurongwa zvakare.

5.4.6 Bvisa guruva uye kucheka pandiro yekudziya (Usakwenya PTFE layer pamusoro pendiro yekudziya).

5.4.7 Isa ndiro yekudziisa mufuremu mushure mekunge yawana tembiricha inodiwa. Simudza kudzvanya kusvika kutaurwa nekuita pachibato kusvika bead yasvika paurefu hunodiwa.

5.4.8 Deredza kudzvanya kune kukosha kunokwana kuchengetedza mativi ese achigunzva nendiro yekudziya kwenguva yakatarwa.

5.4.9 Kana nguva yapera patsanura furemu uye bvisa ndiro yekudziya, batanidza mativi maviri nekukurumidza.

5.4.10 Wedzera kudzvanya kusvika bead inodiwa yaoneka. Sungai chivharo chekuvhara kuti chibatanidzo chitonhorere chega. Pakupedzisira vhura zvisungiso uye tora iyo yakabatanidzwa pombi.

5.4.11 Tarisa nemaziso majoini. Iko kubatanidzwa kunofanirwa kuve kwakatsetseka symmetry, uye pasi pe groove pakati pemabhesi haifanire kunge yakaderera pane iyo pombi. Kukanganisa kwemabheji maviri hakufanirwe kudarika 10% yemadziro emadziro, kana welding yakaipa.

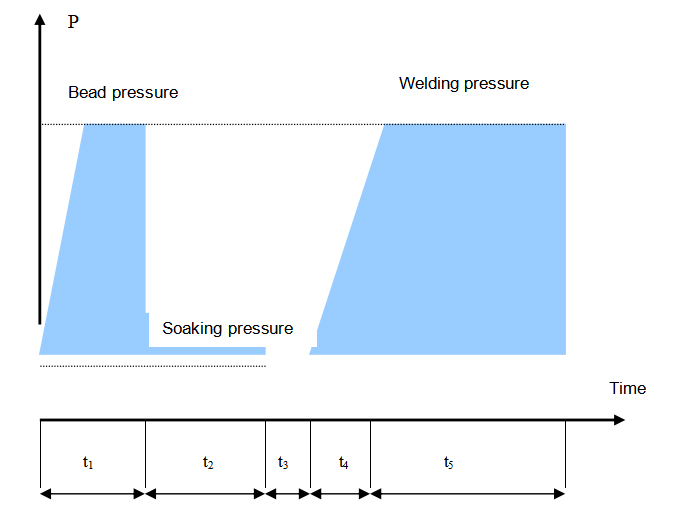

Reference Welding Standard (DVS2207-1-1995)

6.1 Nekuda kwekusiyana kweiyo welding standard uye PE zvinhu, iyo nguva uye kudzvanywa kunosiyana muzvikamu zvakasiyana zvewelding. Inoratidza kuti iwo chaiwo welding parameters anofanirwa kupihwa nemapombi uye fittings 'mugadziri.

| Kukora kwemadziro (mm) | Bead urefu (mm) | Bead kuvaka-up pressure (MPa) | Kunyura nguva t2(sekondi) | Kunyura pressure (MPa) | Kuchinja-nekufamba kwenguva t3(sekondi) | Pressure kuvaka-up nguva t4(sekondi) | Welding pressure (MPa) | Nguva yekutonhodza t5(min) |

| 0~4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45~70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7~12 | 1.5 | 0.15 | 70~120 | ≤0.02 | 6~8 | 6~8 | 0.15±0.01 | 10~16 |

| 12~19 | 2.0 | 0.15 | 120~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16~24 |

| 19~26 | 2.5 | 0.15 | 190 -260 | ≤0.02 | 10~12 | 11~14 | 0.15±0.01 | 24~32 |

| 26~37 | 3.0 | 0.15 | 260~370 | ≤0.02 | 12~16 | 14~19 | 0.15±0.01 | 32~45 |

| 37~50 | 3.5 | 0.15 | 370~500 | ≤0.02 | 16~20 | 19~25 | 0.15±0.01 | 45~60 |

| 50~70 | 4.0 | 0.15 | 500~700 | ≤0.02 | 20~25 | 25~35 | 0.15±0.01 | 60~80 |

Ongorora: Bead kuvaka-up kumanikidza uye welding kudzvanywa mufomu ndiyo inokurudzirwa interface yekumanikidza, iyo geji yekumanikidza inofanirwa kuverengerwa neinotevera formula.

Matauriro:

Welding pressure(Mpa)=(Chikamu che welding pipe ×0.15N/mm2)/(2 ×8×8×3.14) + Dhonza kumanikidza

Here, 1Mpa=1N/mm2