TPWG315 380 GAUGE YITANGAZAMAKURU

Muri make

Hamwe numutungo wibikoresho bya PE bikomeza gutunganywa no kuzamura, umuyoboro wa PE ukoreshwa cyane mugutanga gaze namazi, guta imyanda, inganda zimiti, ibirombe nibindi.

Uruganda rwacu rumaze imyaka irenga icumi rukora ubushakashatsi no guteza imbere imashini ya TPW ya plastike pipe butt fusion imashini ikwiranye na PE, PP, na PVDF.

Uyu munsi, ibicuruzwa byacu birimo ubwoko umunani nubwoko burenga 20 bukoreshwa mubikorwa byo kubaka imiyoboro ya plastiki no gukora fitingi mumahugurwa kuburyo bukurikira:

| SHS ikurikirana ya sock welder | Urutonde rwa TPWC Band yabonye |

| Imashini ya TPW yintoki butt fusion imashini | Imashini yo gusudira ya TPWG |

| Imashini ya TPWY butt fusion imashini | Urukurikirane rw'ibikoresho bidasanzwe |

| Imashini ya QZD Imashini-butt imashini | SHM ikurikirana ya mashini yo guhuza imashini |

Iyi mfashanyigisho ni iy'imashini yo gusudira ya TPWG315 ya plastike. Kugirango wirinde impanuka iyo ari yo yose iterwa n'amashanyarazi cyangwa imashini. Birasabwa gusoma witonze no gukurikiza amategeko yumutekano akurikira mbere yo gukoresha imashini.

Ibisobanuro bidasanzwe

Mbere yo gukoresha imashini, umuntu wese agomba gusoma ibi bisobanuro yitonze kandi akabigumana neza kugirango yizere ibikoresho numutekano wumukoresha, ndetse numutekano wabandi.

2.1 Imashini ikoreshwa mu gusudira imiyoboro ikozwe muri PE, PP, PVDF kandi ntishobora gukoreshwa mu gusudira ibikoresho idasobanuwe, bitabaye ibyo imashini irashobora kwangirika cyangwa impanuka zimwe zishobora kuvamo.

2.2 Ntukoreshe imashini ahantu hashobora guturika

2.3 Imashini igomba gukoreshwa nabakozi bashinzwe, babishoboye kandi bahuguwe.

2.4 Imashini igomba gukorerwa ahantu humye. Ingamba zo gukingira zigomba gufatwa mugihe zikoreshwa mumvura cyangwa kubutaka butose.

2.5 Imashini isaba 380V ± 10%, amashanyarazi ya Hz 50. Niba umugozi wagutse ugomba gukoreshwa, hagomba kubaho igice gihagije ukurikije uburebure bwabo.

Umutekano

3.1 ibimenyetso byumutekano

Ibimenyetso bikurikira byashyizwe kumashini:

3.2 Kwirinda umutekano

Witondere mugihe ukora no gutwara imashini ukurikije amategeko yose yumutekano muri aya mabwiriza.

3.2.1 Menyesha mugihe ukoresha

l Umukoresha agomba kuba ashinzwe kandi yahuguwe.

Kugenzura neza no kubungabunga imashini buri mwaka kubwumutekano na mashini

kwiringirwa.

3.2.2Imbaraga

Agasanduku ko gukwirakwiza amashanyarazi kagomba kugira ikibazo cyubutaka hamwe nubuziranenge bwumutekano w'amashanyarazi. Ibikoresho byose birinda umutekano byerekanwa namagambo cyangwa ibimenyetso byoroshye kumvikana.

3.2.3 Zimya amashanyarazi mbere yo gukuraho igifuniko cyumutekano cyangwa net.

Guhuza imashini kububasha

Imashini ihuza imashini ningufu igomba kuba ihungabana hamwe nibimenyetso bya ruswa. Niba insinga yagutse ikoreshwa, igomba kuba ifite igice kinini cyo kuyobora ukurikije uburebure bwayo.

Ubutaka: Urubuga rwose rugomba gusangira insinga imwe kandi sisitemu yo guhuza ubutaka igomba kuzuzwa no kugeragezwa nabantu babigize umwuga.

3.2.3Kubika ibikoresho by'amashanyarazi

Kuri min. akaga, ibikoresho byose bigomba gukoreshwa no kubikwa neza kuburyo bukurikira:

Irinde gukoresha insinga z'agateganyo zidakurikiza ibisanzwe

※ Ntukore ku bice bya electrophorus

Kubuza gukuramo umugozi kugirango uhagarike

Kubuza gutwara insinga zo guterura ibikoresho

※ Ntugashyire ikintu kiremereye cyangwa gityaye ku nsinga, kandi ugenzure ubushyuhe bwa kabili mu kugabanya ubushyuhe (70 ℃)

Not Ntukore ahantu hatose. Reba niba inkweto n'inkweto byumye.

※ Ntugasenye imashini

3.2.4 Reba imiterere yimashini yimashini buri gihe

※ Reba insulasiyo yinsinga byumwihariko ingingo zasohotse

※ Ntugakoreshe imashini mubihe bikabije.

※ Reba niba switch yamenetse ikora neza byibura buri cyumweru.

※ Reba ubutaka bwimashini nabakozi babishoboye

3.2.5 Sukura kandi urebe neza imashini

※ Ntugakoreshe ibikoresho (nka abrasive, nibindi byuma) byangiza insulation byoroshye mugihe cyoza imashini.

. Menya neza ko imbaraga zaciwe mugihe urangije akazi.

※ Menya neza ko nta byangiritse muri mashini mbere yo kuyikoresha.

Niba gusa ibikurikira byavuzwe haruguru, kwirinda birashobora gukora neza.

3.2.6 Gutangira

Menya neza niba switch ya mashini ifunze mbere yo kuyifungura.

3.2.7 Gukomera kw'ibice

Menya neza ko imiyoboro ikosowe neza. Menya neza ko ishobora kugenda neza kandi ikayirinda kunyerera.

3.2.8 Ibidukikije

Irinde gukoresha imashini mubidukikije byuzuye irangi, gaze, umwotsi na deoil, kuko kwandura amaso ninzira zubuhumekero byaterwa.

Ntugashyire imashini ahantu handuye.

3.2.9 Umutekano w'abakozi mugihe ukora

Kuraho imitako nimpeta, kandi ntukambare imyenda idakwiriye wirinde kwambara inkweto zinkweto, ubwanwa burebure cyangwa umusatsi muremure ushobora gufatirwa mumashini.

3.3 Umutekano wibikoresho

Imashini yo gusudira Hydraulic ikora gusa numwuga cyangwa umukozi ufite icyemezo cyahuguwe. Umulayiki arashobora kwangiza imashini cyangwa abandi hafi.

3.3.1 Isahani yo gushyushya

Ubushyuhe bwubuso bwa plaque yo gushyushya bushobora kugera kuri 270 ℃ .Ntukigere uyikoraho kugirango wirinde gutwikwa

l Mbere na nyuma yo gukoresha, sukura hejuru ukoresheje umwenda woroshye. Irinde ibikoresho byangiza bishobora kwangiza igifuniko.

l Reba insinga yo gushyushya hanyuma urebe ubushyuhe bwubuso.

3.3.2 Igikoresho cyo gutegura

l Mbere yo kogosha imiyoboro, impera yimiyoboro igomba gusukurwa, cyane cyane koza umucanga cyangwa izindi draff zometse kumpera. Mugukora ibi, ubuzima bwurugero burashobora kuramba, kandi bikarinda no kogosha bajugunywa kubantu babi.

Wemeze ko igikoresho cyo gutegura gifunze cyane kumpera zombi

3.3.3 Ibyingenzi:

l Menya neza ko imiyoboro cyangwa ibikoresho byakosowe neza kugirango ubone guhuza neza.

l Iyo uhuza imiyoboro, uyikoresha agomba kubika umwanya runaka kumashini kugirango umutekano wabakozi.

l Mbere yo gutwara, menya neza ko clamp zose zimeze neza kandi ntizishobora kugwa mugihe cyo gutwara.

Ikoreshwa ryurwego na tekiniki ya tekinike

| Andika | TPWG315 | |

| Ibikoresho byo gusudira | PE, PP, PVDF | |

| Hanze Diameter intera | inkokora (DN , mm) | 90 110 125 140 160 180 200 225 250 280 315mm |

| tee (DN , mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

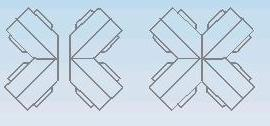

| umusaraba (DN , mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Wyes 45 ° & 60 ° (DN , mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Ubushyuhe bwibidukikije | -5 ~ 45 ℃ | |

| Amavuta ya Hydraulic | 40 ~ 50 (kinematic viscosity) mm2/ s, 40 ℃) | |

| Amashanyarazi | ~ 380 V ± 10 % | |

| Inshuro | 50 Hz | |

| Ibiriho byose | 13 A. | |

| Imbaraga zose | 7.4 KW | |

| Shyiramo, isahani yo gushyushya | 5.15 KW | |

| Gutegura moteri | 1.5 KW | |

| Moteri ya Hydraulic | 0,75 KW | |

| Kurwanya kurwanya | > 1MΩ | |

| Icyiza. umuvuduko w'amazi | 6 MPa | |

| Igice cyose cya silinderi | Cm 12,562 | |

| Icyiza. ubushyuhe bw'isahani | 270 ℃ | |

| Itandukaniro mubushuhe bwubuso bwa plaque | ± 7 ℃ | |

| Ijwi ritifuzwa | < 70 dB | |

| Ikigega cya peteroli | 55L | |

| Uburemere bwose (kg) | 995 | |

Ibisobanuro

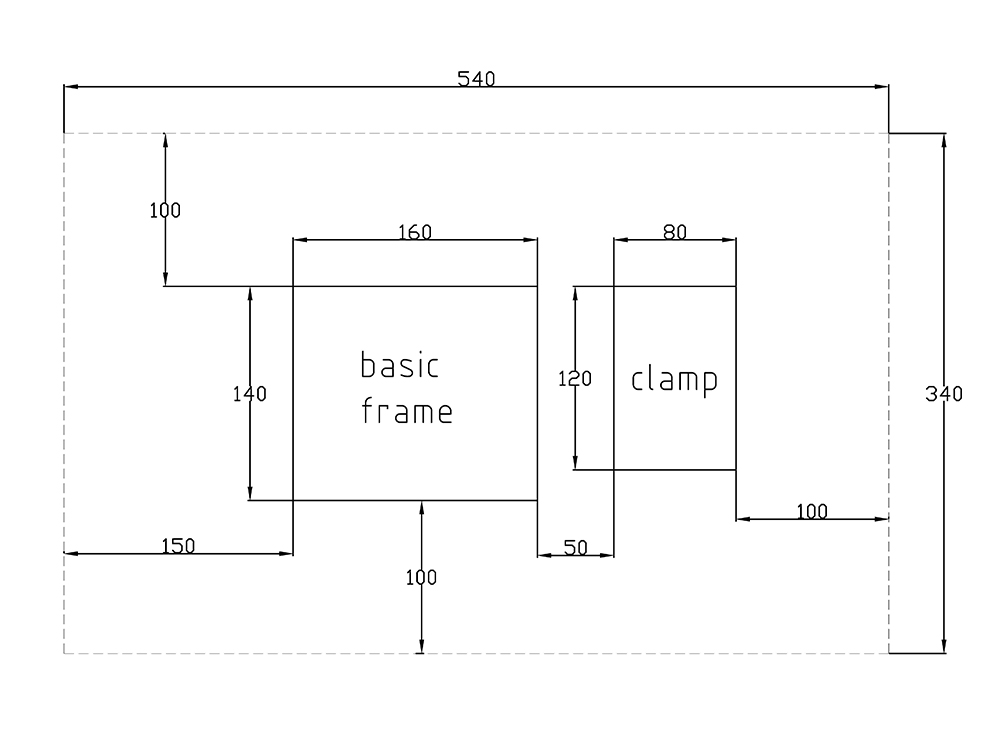

Imashini yo gusudira mumahugurwa irashobora kubyara inkokora, tee, kwambukiranya umuyoboro wa PE mumahugurwa. Clamps zisanzwe zihuye nubunini busanzwe bwa pipine ukurikije ISO161 / 1.

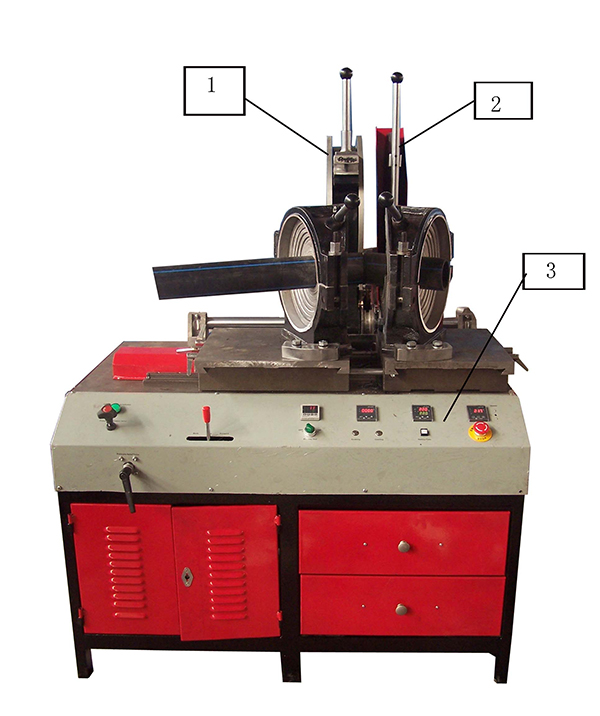

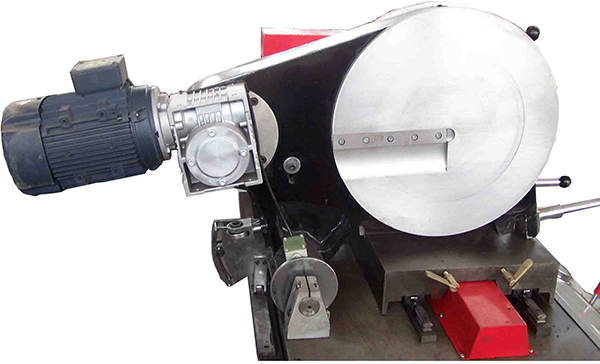

5.1 Imashini nyamukuru

| 1. Igikoresho cyo gutegura | Isahani yo gushyushya | 3. Ikibaho |

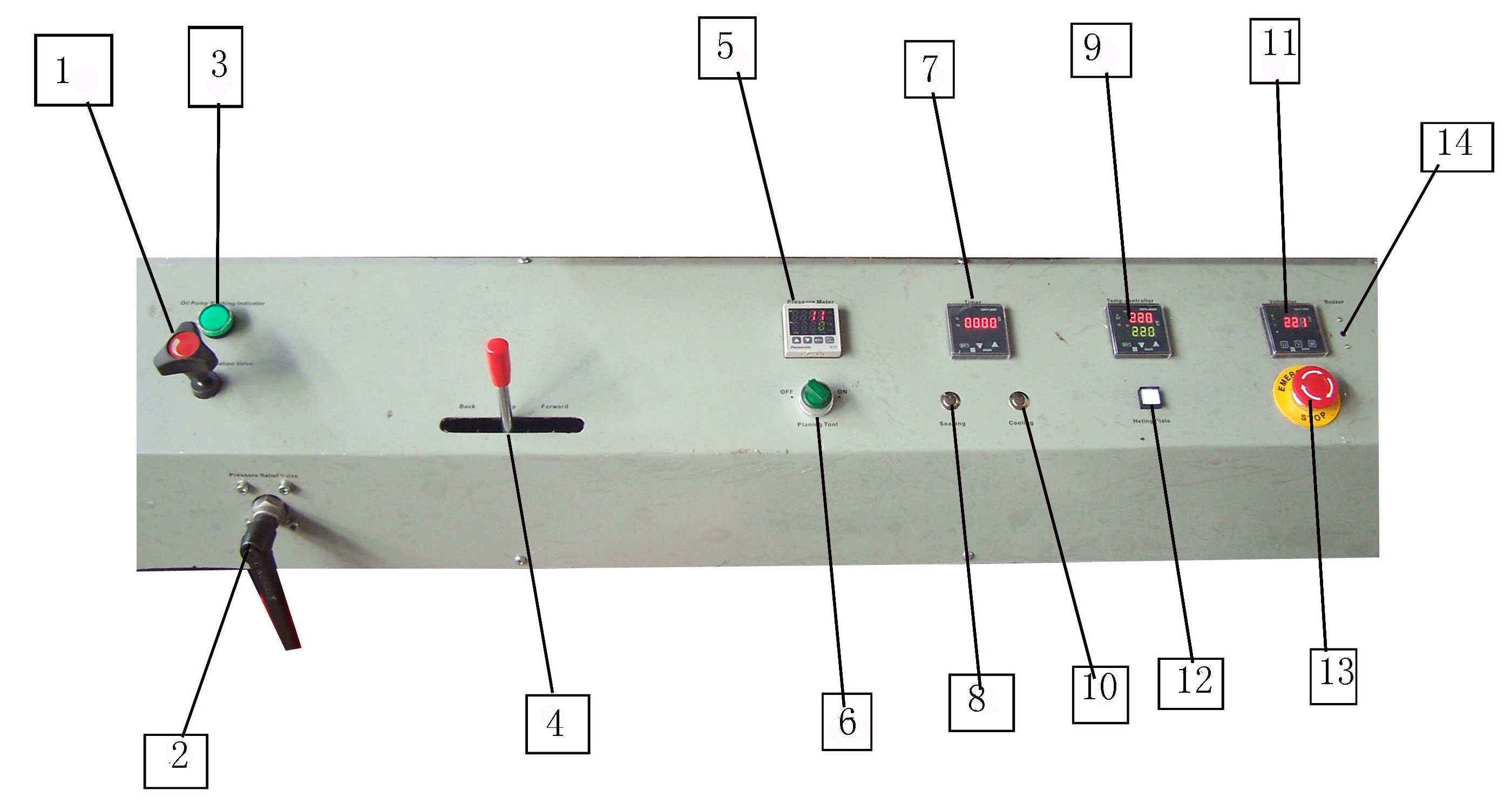

5.2 Ikibaho

| 1. Agaciro kigenga igitutu | 2. Umuvuduko w'ingutu | 3. Ibipimo byerekana pompe yamavuta | 4. Agaciro kayobora |

| 5. Ikigereranyo cya Pressure | 6. Gutegura Buto | 7. Igihe | 8. Kunyunyuza igihe |

| 9. Ibipimo byo kugenzura ubushyuhe | 10. Ibihe bikonje | 11. Voltmeter | 12. Guhindura ubushyuhe |

| 13. Guhagarara byihutirwa | 14. Buzzer |

Kwinjiza

6.1 Kuzamura no gushiraho

Mugihe cyo guterura no gushiraho imashini igomba kubikwa itambitse, kandi ntizigere ihindagurika cyangwa ngo ihindure kugirango wirinde kwangirika udashaka.

6.1.1 Niba hakoreshejwe forklift, igomba kwinjizwa neza witonze uhereye munsi yimashini witonze kugirango wirinde kwangiza amavuta ya shitingi

6.1.2 Mugihe cyo kugeza imashini kumwanya wo kwishyiriraho, ibyingenzi bigomba guhora bihamye kandi bitambitse.

6.1.3 Shyira moteri kumasanduku yo kugabanya igikoresho cyateguwe kandi ushyizwemo imigozi, yerekanwe ku gishushanyo cya3.

6.2 Kwihuza

Menya neza ko umwanya uhagije kugirango ushyire imashini kandi ugumane imashini yose itambitse kandi wizere ko uhuza neza socket zose, insinga na hose mugihe ushyira imashini.

6.2.1 Huza imashini nyamukuru kumasanduku yamashanyarazi.

Igishushanyo cya 4 Huza isahani yo gushyushya agasanduku k'amashanyarazi

Igishushanyo 5 Huza igikoresho cyo gutegura agasanduku k'amashanyarazi

6.2.2 Guhuza umugozi wimashini kububasha, aribwo ibyiciro bitatu- insinga eshanu 380V 50HZ.

Kubwumutekano, imashini igomba gutoborwa kuva hasi yimashini.

6.2.3 Uzuza amavuta ya hydraulic yungurujwe. Uburebure bwamavuta bugomba kuba burenze 2/3 byuburebure bwurwego rwibipimo.

Iburira: Ubutaka bugomba kurangizwa nabantu babigize umwuga.

Amabwiriza yo Gukoresha

Kurikiza amategeko yose yumutekano kuri mashini. Umuntu udahuguwe ntabwo yemerewe gukora imashini.

7.1 Imbaraga

Funga ikosa ryubutaka

7.2 Tangira pompe yamavuta

Tangira pompe yamavuta kugirango urebe icyerekezo kizunguruka. Niba igipimo cyumuvuduko gifite ibyasomwe, kuzenguruka ni byiza, niba atari byo, guhana insinga ebyiri nzima.

7.3 Reba kandi uhindure umuvuduko wo gukurura no kwimura umuvuduko wa plaque. Umuvuduko wakazi wa sisitemu ni 6 MPa. Umuvuduko wo guhuza urashobora guhindurwa nigitutu cyumuvuduko wumuvuduko uri kumwanya ugenzura. Umuvuduko woguteganya ugomba kwiyongera buhoro buhoro, kandi ukabigumana mugihe gikomeza kugaragara (ntabwo ari kinini). Kugaburira umuvuduko wo gukurura isahani irashobora guhindurwa binyuze muri cheque valve (imbere shingiro).

7.4 Kwishyiriraho

Shyiramo intebe y'ibumoso n'iburyo (clamps ya tees cyangwa inkokora) ukurikije ibikoresho bigomba guhimbwa.

1) Bikosore ubanza ukoresheje pin yo gufunga ifatanye na mashini;

2) Hindura inguni hamwe nigikoresho cyihariye kidasanzwe;

3) Kenyera umugozi wo gufunga ukoresheje umugozi.

Niba inkokora zinkokora zikeneye gukoreshwa, kanda cyane hamwe nisahani yo gufunga nyuma yo guhindura inguni.

7.5 Shiraho ubushyuhe bwagenwe kugenzura ubushyuhe ukurikije uburyo bwo gusudira imiyoboro. (Reba igice cya 7.10)

7.6 Mbere yo kuzamura cyangwa kumanura igikoresho cyo gutegura fungura igikoresho cyo gufunga.

7.7 Imiyoboro ihagaze muri mashini

7.7.1 Tandukanya clamp ya mashini ukoresheje leveri yicyerekezo

7.7.2 Shyira imiyoboro muri clamp hanyuma uyizirike; umwanya uri hagati yimiyoboro ibiri igomba kuba ihagije kubikoresho byo gutegura.

7.7.3 Funga igitutu cyo kugabanya umuvuduko, mugihe ufunze impande zombi, hinduranya valve igenga umuvuduko kugeza igipimo cyumuvuduko cyerekana umuvuduko wa fusion, ugenwa nibikoresho byumuyoboro.

7.8 Gutegura

7.8.1 Tandukanya clamps ukoresheje icyerekezo cyerekezo kandi ufungure byimazeyo igitutu cyo gutabara.

7.8. mpande. Icyitonderwa: 1) Ubunini bwogosha bugomba kuba muri 0.2 ~ 0.5mm kandi burashobora guhinduka muguhindura uburebure bwigikoresho cyo gutegura.

2) Umuvuduko wo gutegura ntugomba kurenza MPa 2.0 kugirango wirinde kwangirika kwigikoresho cyo gutegura.

7.8.3 Nyuma yo gutegura, Tandukanya clamp hanyuma ukureho igikoresho cyo gutegura.

7.8.4 Funga impande zombi kugirango uhuze. Niba kudahuza birenze 10% byubugari bwumuyoboro, binoze muguhambura cyangwa gukomera clamp yo hejuru. Niba ikinyuranyo kiri hagati yimpera kirenze 10% yuburebure bwurukuta rwumuyoboro, ongera utegure umuyoboro kugeza ubonye ibisabwa.

7.9 Gusudira

7.9.1 Shiraho igihe cyo gushiramo nigihe cyo gukonjesha ukurikije inzira yo gusudira.

7.9.2.1). Umuyoboro urangirira ku isahani yo gushyushya hanyuma guhuza bigatangira.

7.9.3 Iyo isaro ntoya yubatse, subiza inyuma icyerekezo cyerekezo hagati kugirango ukomeze igitutu. Hindura swing kugenzura valve kugirango ugabanye umuvuduko wo gushiramo ingufu (P.2) Hanyuma ufunge vuba. Noneho kanda hasi buto yo gushiramo umwanya kumwanya.

7.9.4 Nyuma yo gushiramo (impuruza ya buzzer), fungura clamp ukoresheje icyerekezo cyerekezo hanyuma ukureho isahani yo gushyushya vuba.

7.9.5 Ihuze impera zombi zashonze vuba hanyuma ugumane icyerekezo cyerekezo kuri "imbere" mugihe gito hanyuma usubize mumwanya wo hagati kugirango ukomeze igitutu. Muri iki gihe, ibyasomwe mu gipimo cyerekana igitutu ni ugushiraho igitutu cyo guhuza (niba atari byo, uhindure ukora kuri valve igenga umuvuduko).

7.9.6 Shyira hasi buto yo gukonjesha igihe gukonja bitangiye. Nyuma yo gukonja birangiye, buzzer iratabaza. Kuraho igitutu cya sisitemu ukora kuri valve yubutabazi, fungura clamp hanyuma ukureho ingingo.

7.9.7 Reba ingingo ukurikije ibipimo byo gusudira.

7.10 Igenzura ry'ubushyuhe hamwe nigihe

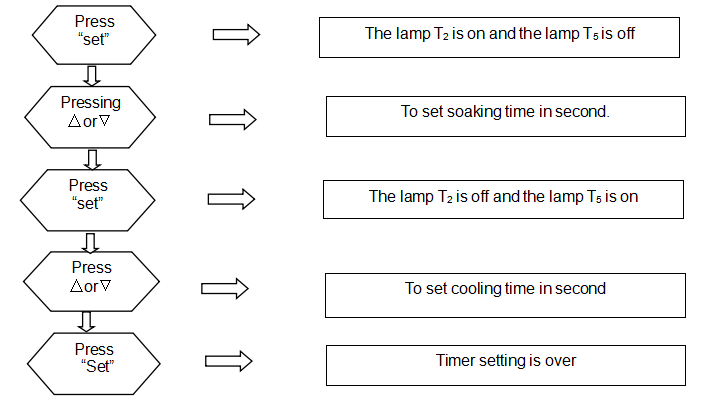

7.10.1 Kugena igihe

7.10 Igenzura ry'ubushyuhe hamwe nigihe

7.10.1 Kugena igihe

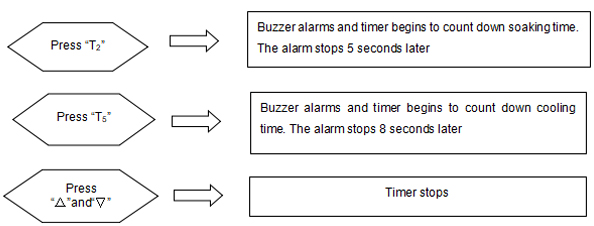

7.10.2 Gukoresha igihe

7.10.3 Igenamiterere ry'ubushyuhe

1) Kanda "SET" mumasegonda irenga 3 kugeza "sd" yerekanwe mumadirishya yo hejuru

2) Kanda "∧" cyangwa "∨" kugirango uhindure agaciro kubushyuhe bwihariye (kanda "∧" cyangwa "∨" ubudahwema, agaciro kaziyongera cyangwa gukuramo mu buryo bwikora)

3) Nyuma yo gushiraho, kanda "SET" kugirango usubire kugenzura no kugenzura interineti

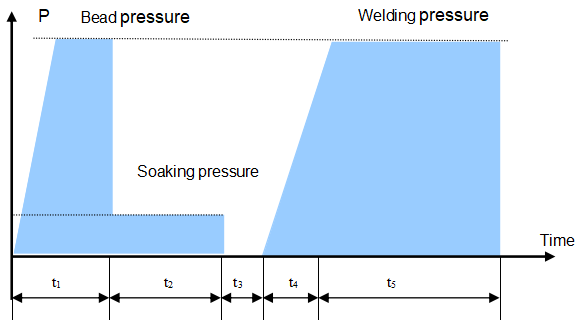

Reba Welding Standard (DVS2207-1-1995)

8.1 Kuberako ibipimo bitandukanye byo gusudira nibikoresho bya PE, igihe nigitutu cyicyiciro cyibikorwa byo guhuza biratandukanye. Irerekana ko ibipimo byo gusudira bigomba kugaragazwa nu miyoboro n’ibikoresho

8.2 Urebye ubushyuhe bwo gusudira bwimiyoboro ikozwe muri PE 、 PP na PVDF na DVS isanzwe iri hagati ya 180 ℃ kugeza 270 ℃. Ubushyuhe bwo gukoresha ubushyuhe buri muri 180 ~ 230 and, na Max. ubushyuhe bwo hejuru bushobora kugera kuri 270 ℃.

8.3 Ibipimo ngenderwahoDVS2207-1-1995

| Ubunini bw'urukuta (Mm) | Uburebure bw'amasaro (mm) | Igitutu cyo kubaka amashanyarazi (MPa) | Umwanya t2(Sec) | Umuvuduko ukabije (MPa) | Guhindura-igihe t3(Sec) | Umuvuduko wo kubaka -igihe t4(Sec) | Umuvuduko wo gusudira (MPa) | Igihe cyo gukonja t5(Min) |

| 0 ~ 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15 ± 0.01 | 6 |

| 4.5 ~ 7 | 1.0 | 0.15 | 45 ~ 70 | ≤0.02 | 5 ~ 6 | 5 ~ 6 | 0.15 ± 0.01 | 6 ~ 10 |

| 7 ~ 12 | 1.5 | 0.15 | 70 ~ 120 | ≤0.02 | 6 ~ 8 | 6 ~ 8 | 0.15 ± 0.01 | 10 ~ 16 |

| 12 ~ 19 | 2.0 | 0.15 | 120 ~ 190 | ≤0.02 | 8 ~ 10 | 8 ~ 11 | 0.15 ± 0.01 | 16 ~ 24 |

| 19 ~ 26 | 2.5 | 0.15 | 190 ~ 260 | ≤0.02 | 10 ~ 12 | 11 ~ 14 | 0.15 ± 0.01 | 24 ~ 32 |

| 26 ~ 37 | 3.0 | 0.15 | 260 ~ 370 | ≤0.02 | 12 ~ 16 | 14 ~ 19 | 0.15 ± 0.01 | 32 ~ 45 |

| 37 ~ 50 | 3.5 | 0.15 | 370 ~ 500 | ≤0.02 | 16 ~ 20 | 19 ~ 25 | 0.15 ± 0.01 | 45 ~ 60 |

| 50 ~ 70 | 4.0 | 0.15 | 500 ~ 700 | ≤0.02 | 20 ~ 25 | 25 ~ 35 | 0.15 ± 0.01 | 60 ~ 80 |

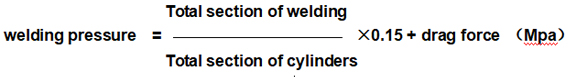

Icyitonderwa pressure Umuvuduko w-isaro hamwe nigitutu cyo gusudira muburyo nuburyo bwifuzwa busabwa, igitutu cyo gupima kigomba kubarwa hamwe na formula ikurikira.

Uburyo bwo Guhuza Ibihimbano

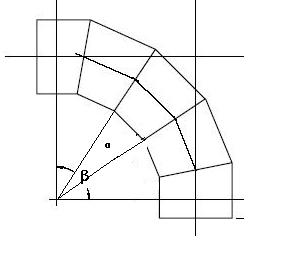

9.1 Gukora inkokora

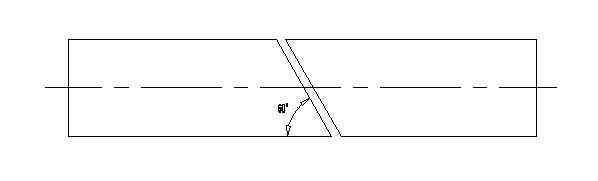

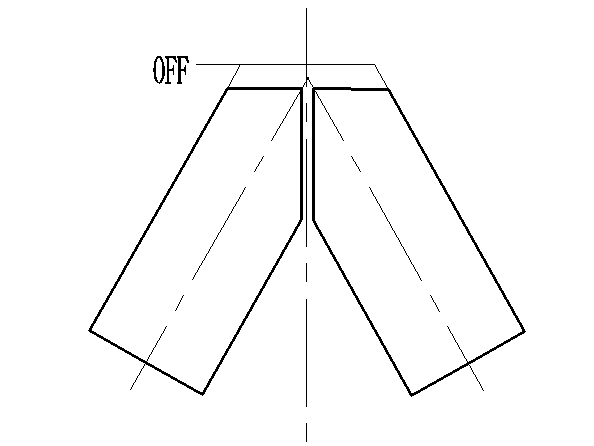

9.1.1 Ukurikije inguni yinkokora nubunini bwibice byo gusudira, inguni yo gusudira hagati ya buri gice irashobora guhitamo.

Ibisobanuro: α - inguni yo gusudira

- Inguni y'inkokora

n - ingano y'ibice

Kurugero: Inkokora 90 ° igabanijwemo ibice bitanu bigomba gusudwa, inguni yo gusudira α = β / (n-1) = 90 ° / (5-1) = 22.5 °

9.1.2 Ingano ya min ya buri gice cyo gusudira mubice byo gusudira ingano igabanywa nitsinda ryabonye ukurikije inguni.

Ibisobanuro:

D - diameter yo hanze yumuyoboro

L - Uburebure buke bwa buri gice

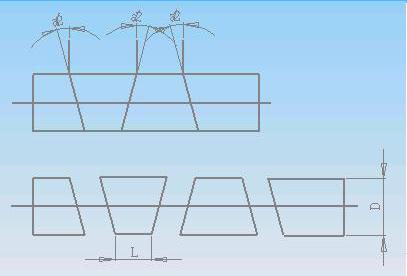

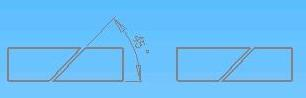

9.2 Uburyo bwo gutanga amase

9.2.1 Ibikoresho ni igishushanyo gikurikira:

9.2.2 Gusudira nk'imiterere y'ishusho:

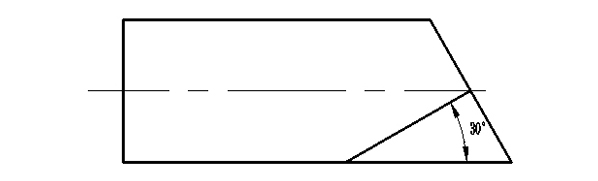

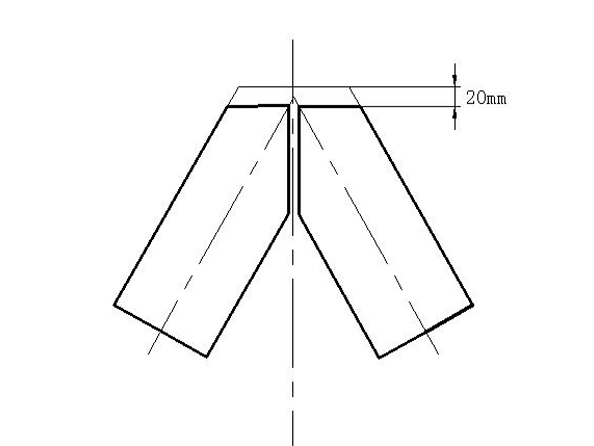

9.2.3 Inguni yaciwe nkigishushanyo

Icyitonderwa: Igipimo “a” ntigomba kuba munsi ya 20㎜kuri nko guteganya intera no kwishyura isaro ishonga.

9.2.4 Gusudira nkibishushanyo mbonera, tees zakozwe.

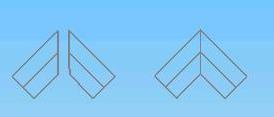

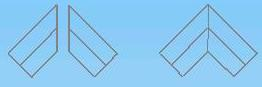

9.3 Uburyo bwo guhuza imiyoboro ingana na diameter ingana

9.3.1 Ibikoresho byaciwe nkigishushanyo gikurikira

9.3.2 Ihuriro ryombi rirasudwa nkimiterere yishusho:

9.3.3 Inguni yaciwe nkigishushanyo:

Icyitonderwa: Igipimo “a” ntigomba kuba munsi ya 20㎜, Iteganya margin no kwishyura isaro ishonga.

9.3.4 Yasuditswe nkimiterere yishusho.

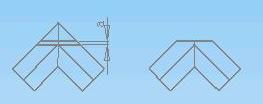

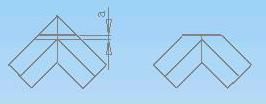

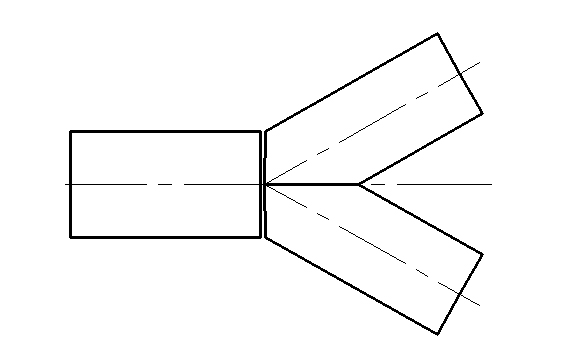

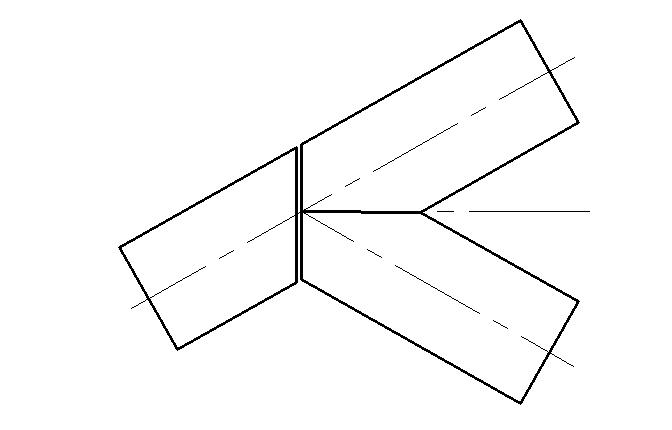

9.4 Uburyo bwa "Y" imiterere yimiterere ihimba (45 ° cyangwa 60 °)

9.4.1 gukata nkigishushanyo gikurikira (fata 60 ° “Y” imiterere yimiterere nkurugero)

9.4.2 Komeza kuri welding yambere nkibishushanyo bikurikira:

9.4.3 Hindura clamp hanyuma ukomeze gusudira kabiri.

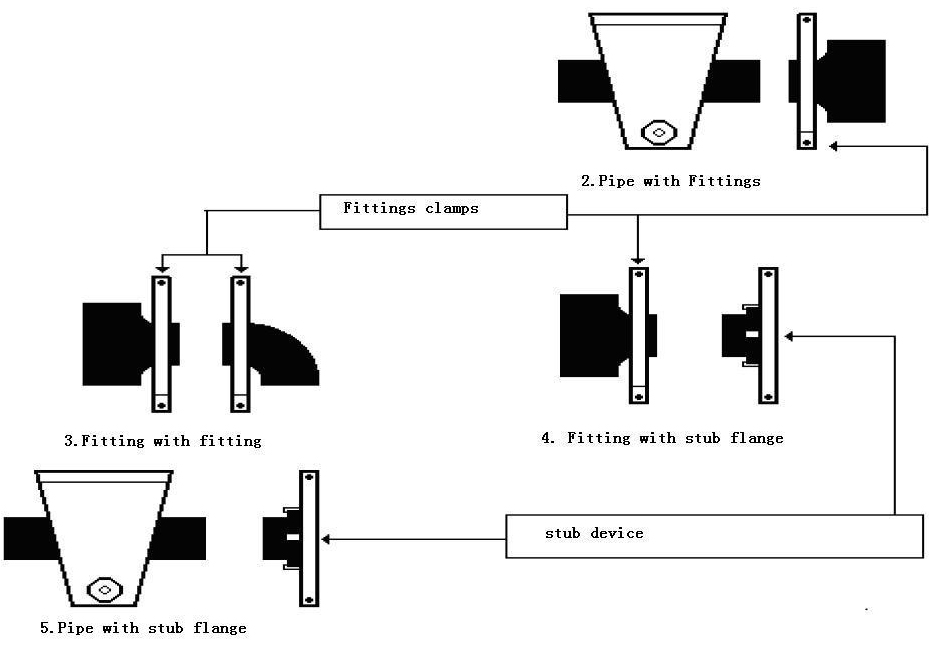

9.5 ibindi bikoresho byo gusudira

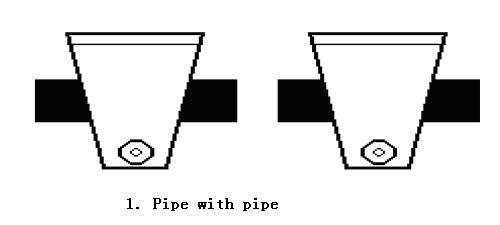

9.5.1. Umuyoboro ufite umuyoboro

9.5.2. Umuyoboro ukwiye

9.5.3

9.5.4 Bikwiranye na stub flange

9.5.5 Umuyoboro hamwe na stub flange

Imikorere idasesenguye nigisubizo

10.1 Guhuza kenshi ibibazo byubuziranenge gusesengura:

10.2 Kubungabunga

u PTFE isize isahani

Nyamuneka nyamuneka witondere gukoresha indorerwamo yo gushyushya kugirango wirinde kwangirika kwa PTFE.

Komeza guhora usukuye hejuru ya PTFE, isuku igomba gukorwa nubushuhe bushyushye ukoresheje umwenda woroshye cyangwa impapuro, wirinde ibikoresho byangiza bishobora kwangiza ubuso bwa PTFE.

Mubihe bisanzwe, turagusaba:

- Sukura hejuru ukoresheje ibikoresho byihuta byuka (alcool)

- Reba gukomera kwinsinga hamwe na kabili nuburyo ucomeka

u Igikoresho cyo gutegura

Birasabwa cyane guhora usukuye ibyuma no koza pulle ukoresheje icyuma.

Mubihe bisanzwe, ukora ibikorwa byogusukura byuzuye hamwe namavuta yo mumbere

u Hydraulic

Igice cya hydraulic ntabwo gikeneye kubungabungwa nyamara amabwiriza akurikira agomba gukurikizwa:

a. Reba buri gihe amavuta atambitse kandi mugihe wongeyeho ubwoko bwamavuta:

Utambitse ntugomba kuba munsi ya cm 5 uhereye kuri tank ntarengwa.

Kugenzura buri minsi 15 y'akazi birasabwa cyane.

b. Simbuza rwose amavuta buri mezi 6 cyangwa nyuma yamasaha 630 yakazi.

c. Komeza usukure hydraulic unit witonze cyane kuri tank hamwe no guhuza vuba.

10.3 Isesengura ryimikorere kenshi nigisubizo

Mugihe cyo gukoresha, hydraulic unit hamwe nu mashanyarazi birashobora kugaragara ibibazo bimwe. Imikorere mibi ikunze gutondekwa kuburyo bukurikira:

Nyamuneka koresha ibikoresho bifatanye, ibice byabigenewe cyangwa ibindi bikoresho hamwe nicyemezo cyumutekano mugihe ukomeza cyangwa usimbuze ibice. Ibikoresho nibice bidafite icyemezo cyumutekano birabujijwe gukoreshwa.

| Imikorere mibi ya hydraulic | |||||

| No | imikorere mibi | gusesengura | ibisubizo | ||

| 1 | Moteri ntabwo ikora |

irekuwe

| |||

| 2 | Moteri izunguruka buhoro hamwe n urusaku rudasanzwe |

| kurenza MPa

| ||

| 3 | Silinderi ikora bidasanzwe |

ifunze cyane

| gusohoka mu kirere. | ||

| 4 | Gukurura isahani yimuka ya silinderi ntabwo ikora |

valve irahagaritswe |

kurengerwa na valve (1.5 MPa birakwiye).

| ||

| 5 | Amashanyarazi yamenetse | 1. Impeta y'amavuta ni amakosa2. Silinderi cyangwa piston yangiritse nabi | 1. Simbuza impeta y'amavuta2. Simbuza silinderi | ||

| 6 | Umuvuduko ntushobora kwiyongera cyangwa guhindagurika ni binini cyane | 1. Intandaro ya valve yuzuye irahagaritswe.2. Pompe irekura.3. Igice cya pompe ihuriweho hamwe cyangwa urufunguzo rwibanze ni skid. | 1. Sukura cyangwa usimbuze intandaro irenga-valve2. Simbuza amavuta pompe3. Simbuza umugozi uhuriweho | ||

| 7 | Gukata igitutu ntibishobora guhinduka | 1. Umuzunguruko ni amakosa2. Igikoresho cya electromagnetic coil nikosa3. Umuyoboro wuzuye urahagaritswe4. Gukata valve yuzuye birenze urugero | 1. Reba umuzunguruko (diodein itukura coil ya electromagnetic coil irabagirana) 2. Simbuza amashanyarazi ya electronique. Sukura intandaro yo gutembera hejuru ya valve4. Reba gukata hejuru ya valve | ||

| Imikorere mibi yumuriro wamashanyarazi | |||||

| 8 | Imashini yose ntabwo ikora |

| 1. Reba umugozi w'amashanyarazi2. Reba imbaraga zakazi3. Fungura ikosa ryubutaka | ||

| 9 | Ingendo zo guhindura amakosa |

| 1. Reba insinga z'amashanyarazi2. Reba ibintu by'amashanyarazi.3. Reba igikoresho cyo hejuru-gifite imbaraga | ||

| 10 | Ubushyuhe budasanzwe buriyongera |

4. 4. Niba ubushakashatsi bugenzura ubushyuhe burenze 300 ℃, byerekana ko sensor ishobora kwangirika cyangwa ihuriro rikarekurwa. Niba umugenzuzi wubushyuhe yerekana LL, ibyo bikaba byerekana ko sensor ifite uruziga rugufi. Mugenzuzi wubushyuhe yerekana HH, byerekana ko uruziga rwa sensor rufunguye. 5. Kosora ubushyuhe ukoresheje buto iri kumugenzuzi wubushyuhe.

| abahuza

umugenzuzi

shiraho ubushyuhe

abahuza nibiba ngombwa | ||

| 11 | Gutakaza ubushobozi iyo ushushe | Itara ritukura rirabagirana, ariko ubushyuhe buracyazamuka, ni ukubera ko umuhuza ari amakosa cyangwa ingingo 7 na 8 ntizishobora gufungura iyo zibonye ubushyuhe bukenewe. | Simbuza ubushyuhe | ||

| 12 | Igikoresho cyo gutegura ntabwo kizunguruka | Guhindura imipaka ntigikora cyangwa ibice byubukanishi bwibikoresho byo gutegura byaciwe. | Simbuza imipaka igikoresho cyo gutegura hindura cyangwa uduce duto | ||

Umuzenguruko & Hydraulic Igice Igishushanyo

11.1 Igishushanyo cyibice byumuzingi (bigaragara kumugereka)

11.2 Igishushanyo cya Hydraulic igishushanyo (kiboneka kumugereka)

Imbonerahamwe y'akazi