TPWY630/400 BUTT FUSION MACHINE OPERATION MANUAL

Ntchito Range Ndi Technical Parameter

| Mtundu | TPWY-630/400 |

| Zipangizo | PE, PP ndi PVDF |

| Mtundu wa diameter | 400㎜ ~ 630㎜ |

| Kutentha kozungulira. | -5~45℃ |

| Magetsi | 380 V± 10%, 50Hz |

| Mphamvu zonse | 12.2kw |

| Kuphatikizanso: mbale yotenthetsera | 9.2kw |

| Chida chokonzekera | 1.5kw |

| Gawo la Hydraulic | 1.5kw |

| Max. Kupanikizika | 6.3 Mpa |

| Chigawo chonse cha masilinda | 23.06cm kutalika2 |

| Mafuta a Hydraulic | YA-N32 |

| Max. Kutentha | <270℃ |

| Kusiyana kutentha kwa Kutentha mbale mawonekedwe | ± 7℃ |

| Kulemera konse, Kg | 635 |

Kufotokozera Kwapadera

Tikukulimbikitsani kuti muwerenge zolemba zonse mosamala kwambiri kuti mutsimikizire chitetezo cha woyendetsa ndi zida musanayambe kugwiritsa ntchito makinawo. Bukuli liyenera kusungidwa mosamala kuti ligwiritsidwe ntchito mtsogolo.

3.1 zida izi si yoyenera chifukwa palibe kufotokoza zinthu chitoliro kuwotcherera; mwinamwake zikhoza kuwononga kapena kuchitika mwangozi.

3.2 Osagwiritsa ntchito makina pamalo owopsa.

3.3 Makinawa ayenera kugwiritsidwa ntchito ndi akatswiri.

3.4 Makinawa azigwiritsidwa ntchito pamalo owuma. Njira zodzitetezera ziyenera kutengedwa ngati zikugwiritsidwa ntchito pamvula kapena pamtunda.

3.5 Mphamvu yolowera ndi 380V±10%, 50Hz. Ngati agwiritsa ntchito mzere wowonjezera wolowera, mzerewo uyenera kukhala ndi gawo lotsogolera lokwanira.

ApplicationsKufotokozera Kwa Magawo

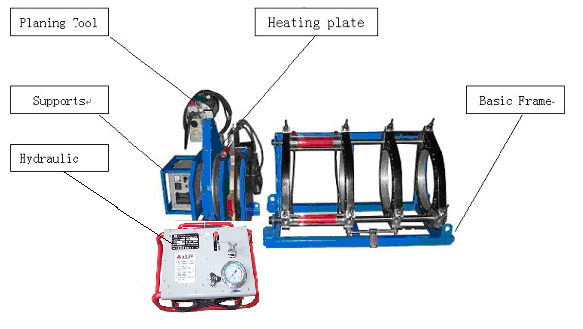

Makinawa amapangidwa kuchokera ku chimango choyambira, hydraulic unit, mbale yotenthetsera, chida chokonzekera, kuthandizira chida chokonzekera ndi bokosi lamagetsi.

4.1 makina kasinthidwe

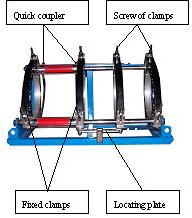

4.2 Choyambirira chimango

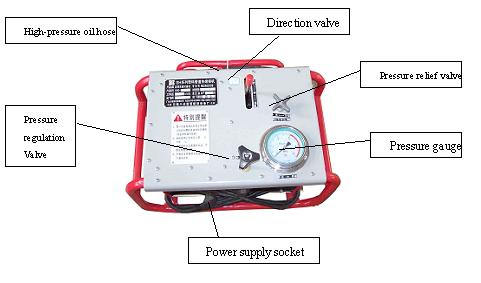

4.3 ma hydraulic mayunitsi

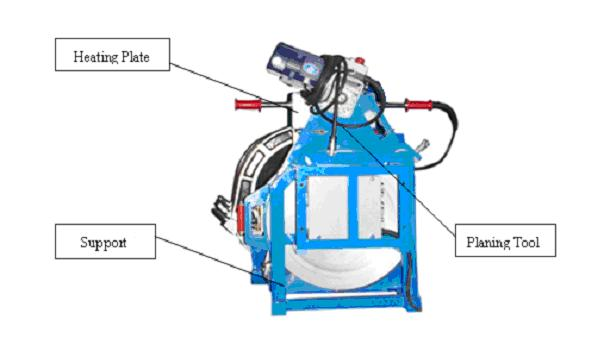

4.4 Chida chokonzera ndi kutentha mbale

Malangizo Ogwiritsa Ntchito

5.1 Zigawo zonse za zida ziyenera kuyikidwa pa ndege yokhazikika komanso yowuma kuti igwire ntchito.

5.2 Onetsetsani mphamvu molingana ndi makina ophatikizira a butt omwe adafunsidwa, makinawo ali m'malo abwino, chingwe chamagetsi sichinasweka, zida zonse ndizabwinobwino, masamba a chida chokonzekera ndi chakuthwa, magawo onse ofunikira ndi zida zatha.

5.3 Kulumikizana kwa Hydraulic ndi magetsi

5.3.1 kulumikiza chimango choyambira ndi hydraulic unit ndi quick coupler.

5.3.2 kulumikiza mbale yotenthetsera ku bokosi lamagetsi mu chimango choyambira.

5.3.3 Lumikizani chingwe chotenthetsera ku mbale yotenthetsera.

5.3.4 Ikani zoyikamo molingana ndi m'mimba mwake wa chitoliro / chofikira ku chimango choyambira.

5.4 Njira yowotcherera

5.4.1 Onani m'mimba mwake ndi makulidwe a khoma kapena SDR ya mapaipi / zokokera kuti zikhale zowotcherera ndizolondola. Pamwamba pake ayenera cheke asanayambe kuwotcherera, ngati zikande upambana 10% khoma makulidwe, ayenera tsankho kudula ntchito.

5.4.2 Yeretsani mkati ndi kunja kwa chitoliro kuti muwotchedwe.

5.4.3 Ikani mapaipi/zoyikamo m'zoyikapo za chimango, kutalika kwa mapaipi/zolumikizira kumapeto kuti ziwotchedwe zotulukapo mwina ndizofanana (zaufupi momwe mungathere). Mapeto ena a chitoliro ayenera kuthandizidwa ndi odzigudubuza kuti achepetse kukangana. Kenako gwetsani zomangira kuti mugwire mapaipi/zokwanira.

5.4.4 Ikani chida chokonzekera mu chimango pakati pa mipope / zozolowera kumapeto ndikuyatsa, kutseka mipope / zokokera kumapeto pogwiritsa ntchito valavu yoyendetsera ma hydraulic unit mpaka pakhale kumeta kosalekeza kumawonekedwe onse.(kumeta kutsika kuchepera 2.0 Mpa). Ikani chowongolera cha valve pamalo apakati ndikusunga masekondi pang'ono, kenako tsegulani chimango, zimitsani chida chokonzera ndikuchichotsa pa chimango. Makulidwe a shavings ayenera kukhala 0.2 ~ 0.5 mm ndipo amatha kusinthidwa ndikusintha kutalika kwa masamba a zida zokonzekera.

5.4.5 Tsekani nsonga za chitoliro/zokwanira ndikuyang'ana kusalunjika kwawo. The max. Kuyika molakwika sikuyenera kupitirira 10% ya makulidwe a khoma, kumatha kusinthidwa ndikusintha kalozera wa chitoliro ndikumasula kapena kumangitsa zomangira. Kusiyana pakati pa malekezero awiri a chitoliro sikuyenera kupitirira 10% ya makulidwe a khoma, kapena kudulidwanso.

5.4.6 Chotsani fumbi ndi kukhalabe pa chotenthetsera mbale (Osakanda PTFE wosanjikiza pamwamba pa chotenthetsera mbale).

5.4.7 Ikani mbale yotenthetsera mu chimango pakati pa chitoliro kumapeto kwa kutentha kofunikira. Yesetsani kukakamiza mpaka momwe mkanda ukukwera.

5.4.8 Chepetsani kupanikizika kwa mtengo womwe ndi wokwanira kuti musunge malekezero onse a mapaipi / zotengera zomwe zimalumikizana ndi mbale yotenthetsera nthawi yolowera.

5.4.9 Nthawi ikakwana, tsegulani chimango ndikutulutsa mbale yotenthetsera, kutseka malekezero awiri osungunuka mwachangu momwe mungathere.

5.4.10 Wonjezerani kukakamiza mpaka kukakamiza kuwotcherera ndikusunga cholumikizira mpaka nthawi yozizira. Kuchepetsa kupanikizika, kumasula zomangira za clamps ndikutulutsa chitoliro cholumikizana.

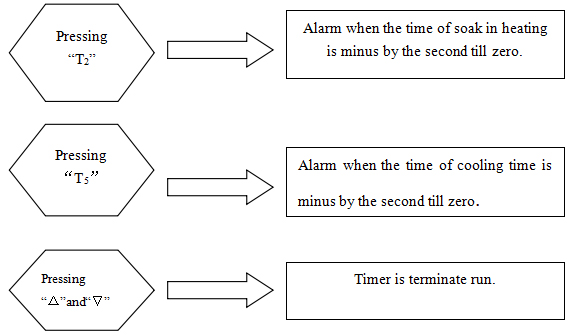

Chida Chanthawi

Ngati chimodzi mwa magawo asinthidwa, monga m'mimba mwake, SDR kapena zinthu za chitoliro, zilowerere mu Kutentha nthawi ndi nthawi yozizira ziyenera bwererani molingana ndi kuwotcherera muyezo.

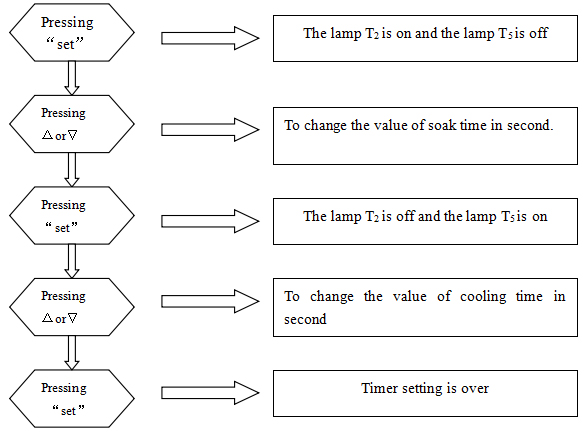

6.1 Kukhazikitsa nthawi

6.2 Malangizo Ogwiritsa Ntchito

Welding Standard Ndi Check

7.1 Chifukwa cha mitundu yosiyanasiyana yowotcherera ndi zinthu za PE, nthawi ndi kupanikizika kwa gawo la kuphatikizika kwa matako ndizosiyana. Zikuonetsa kuti mapaipi ayenera kutsimikizira magawo enieni kuwotcherera ndi zoikamo kupanga.

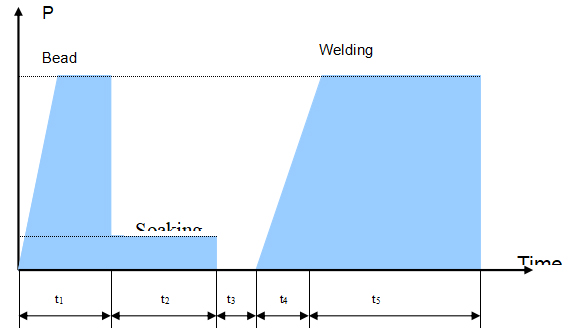

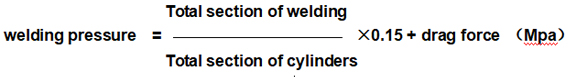

7.2 Reference muyezoDVS2207-1-1995

| Khoma makulidwe (mm) | Kutalika kwa mikanda (mm) | Bead pressure (Mpa) | Kutaya nthawi t2(Sekondi) | Kunyowa pressure (Mpa) | Kusintha - pakapita nthawi t3(Sekondi) | Nthawi yokwera t4(Sekondi) | Welding pressure (Mpa) | Nthawi yozizira t5(mphindi) |

| 0 ~ 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5 ~ 7 | 1.0 | 0.15 | 45; 70 | ≤0.02 | 5; 6 | 5; 6 | 0.15±0.01 | 6; 10 |

| 7; 12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6; 8 | 6; 8 | 0.15±0.01 | 10; 16 |

| 12; 19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8; 10 | 8; 11 | 0.15±0.01 | 16; 24 |

| 19; 26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10; 12 | 11; 14 | 0.15±0.01 | 24; 32 |

| 26; 37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12; 16 | 14; 19 | 0.15±0.01 | 32; 45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16-20 | 19; 25 | 0.15±0.01 | 45-60 |

| 50-70 | 4.0 | 0.15 | 500-700 | ≤0.02 | 20-25 | 25; 35 | 0.15±0.01 | 60-80 |

Ndemanga:

Mawu:

Kupititsa patsogolo Chitetezo

Iwo mwamphamvu ananena kuti kuwerenga ndi kutsatira mosamala zotsatirazi mosamala malamulo pamaso ntchito makina.

8.1 Ogwiritsa ntchito luso ayenera kuphunzitsa asanagwiritse ntchito makinawo.

8.2 Makinawo akuyenera kuyang'ana ndikukonza ndikugwiritsa ntchito zaka ziwiri zapitazo pachitetezo.

8.3 Mphamvu: Pulagi yopangira magetsi imaperekedwa ndi lamulo lachitetezo kwa ogwiritsa ntchito luso komanso chitetezo pamakina.

Malo otetezeka ayenera kukhala ndi mawu kapena chithunzi kuti adziwe.

Lumikizani ndi makina ndi mphamvu: Mphamvu yolowera ndi 380±20V ya 50Hz. Ngati agwiritsa ntchito mzere wowonjezera wolowera, mzerewo uyenera kukhala ndi gawo lotsogolera lokwanira.

Kuyika pansi: Iyenera kukhala ndi chizindikiro chotumizira mzere pamalo omanga, kukana ndi kuyika pansi ndikoyenera kuyika chitetezo ndikuwonetsetsa kuti musapitirire 25 voliyumu ndikuyika kapena kuyesedwa ndi wamagetsi.

Kusungirako magetsi: Makinawa ayenera kukhala ndendende pogwiritsa ntchito kusungirako kuti atsimikizire chitetezo.

Kugwirizana ndi makina kuyenera kutsata malamulo ogwiritsidwa ntchito.

※ Pewani ngozi yamtundu uliwonse chifukwa cha magetsi.

※ Pewani kudula magetsi pokoka

※ Pewani kusuntha, kukokera ndi kuyimitsa makinawo ndi chingwe.

※ Pewani m'mphepete ndikulemera pa chingwe, kutentha kwa chingwe sikuyenera kupitirira 70 ℃.

※ Makinawa ayenera kugwiritsidwa ntchito pamalo owuma. Njira zodzitetezera ziyenera kutengedwa ngati zikugwiritsidwa ntchito pamvula kapena pamtunda.

※ Malo ogwirira ntchito ayenera kukhala oyera.

※ Makinawa ayenera kuyang'anitsitsa ndikukonza nthawi.

※ Nthawi ndi nthawi chingwe cholumikizira chimayenera kuyang'ana ndikuchikanikiza mwapadera

※ Ndizowopsa kugwiritsa ntchito makinawo pakagwa mvula kapena kuli tirigu.

※ Zotsalira zomwe zimagwiritsidwa ntchito panopa ziyenera kukonzedwa mwezi uliwonse.

※ Wothandizira zamagetsi ayenera kuyesa momwe alili.

※ Mukatsuka makina mosamala, musamange makina otetezedwa kapena kugwiritsa ntchito benzini, osabereka ndi zina zotero.

※ Makinawo ayenera kusungidwa mu mawonekedwe odetsedwa.

※ Mapulagi onse ayenera kukhala ndi pulagi kuchokera pamagetsi.

※ Kugwiritsa ntchito makina m'mbuyomu, makinawo ayenera kukhala m'malo abwino ogwirira ntchito.

Iwo amati kuwerenga ndi kutsatira mosamala malamulo mosamala musanagwiritse ntchito makina.

Ngozi yoyambira: makina asanagwiritsidwe ntchito, pulagi yamagetsi imaperekedwa ndi chitetezo.

Mapaipi ayikidwa mu makina:

Ikani mipope mu clamps ndi kumangiriza iwo, mtunda wa awiri chitoliro mapeto ayenera amaika pokonzekera chida ndi inshuwaransi ntchito, kupewa mtundu uliwonse wa ngozi chifukwa cha magetsi ndi opareshoni.

Ntchito ya chikhalidwe:

Malo ogwirira ntchito akuyenera kukhala oyera, owuma komanso owala moyenera.

Ndizowopsa kugwiritsa ntchito makinawo pakagwa mvula kapena kuli tirigu kapena pafupi ndi zakumwa zoyaka.

Samalani kuti anthu onse ozungulira makinawo ali patali.

Zovala:

Sungani mosamala kwambiri mukamagwiritsa ntchito makinawo chifukwa cha kutentha kwambiri komwe kumakhudzidwa ndi mbale yotentha nthawi zonse kuposa 200 ℃, tikulimbikitsidwa kugwiritsa ntchito magolovesi oyenera. Pewani zovala zazitali ndikupewa zibangili, mikanda yomwe ingakokedwe mumakina.

Zindikirani Zowopsa Ndi Pewani Ngozi

Makina opangira matako:

Kugwiritsa ntchito makina kuyenera kuchitidwa mothandizidwa ndi luso.

※ Chipinda chotenthetsera

Kutentha mbale chifukwa cha kutentha kwambiri kuposa 270 ℃, izo amati muyeso:

----gwiritsani ntchito magolovesi otentha kwambiri

---Pali yophatikiza matako ndi chitoliro, mbale yotenthetsera iyenera kuyikidwa.

---Ndamaliza mbale yotenthetsera iyenera kukhala pabokosi.

---amaloledwa kuti asakhudze mbale yotenthetsera.

※ Chida chokonzekera

---Asanayambe ntchito ya Scraping, mapaipi ndi nthaka kupewa kuipitsidwa ndi mapaipi omwe akukumana nawo amatha.

--- anamaliza chida planing ayenera kukhala pa Support kwa planing chida & Kutentha mbale

※ Basic chimango

---anayamba pasadakhale kuti maziko chimango pa tatchulazi kusonkhana Iwo oyenera mitundu yonse ya chitoliro kuti kuwotcherera chitoliro.

---Poyamba kugwira ntchito samalani kuti musasiye miyendo kapena mikono yosunthika. Ndikokakamizidwa kukhala kutali ndi chimango choyambira.

---samalani kuti anthu onse ozungulira makinawo ali patali.

---ogwiritsa ntchito luso ayenera kutsatira malamulo otetezeka.

Kusamalira

| Kanthu | Kufotokozera | Yang'anani musanagwiritse ntchito | Mwezi woyamba | Miyezi 6 iliyonse | Chaka chilichonse |

| Chida chokonzekera | Bwezerani tsamba kapena kukwapula kachiwiri Onani ngati chingwecho chidasweka Onani ngati kugwirizana kwa makina kwamasulidwa |

●

|

● | ● ●

| |

| Kutentha mbale | Yang'anani chingwe ndi ma socket joints Yoyera pamwamba pa Kutentha mbale, valani PTFE wosanjikiza kachiwiri ngati n'koyenera Onani ngati kugwirizana kwa makina kwamasulidwa | ● ●

|

● |

●

| |

| Dongosolo lowongolera kutentha | Onani kutentha chizindikiro Onani ngati chingwecho chidasweka |

● | ● ● | ||

| Hydraulic system | Checkout pressure gauge Yang'anani kuti payipi yamafuta idatayikira, limbitsaninso kapena kuyika zisindikizo Yeretsani fyuluta Onani mafuta ngati mulibe Kusintha mafuta Onani ngati payipi yamafuta yasweka |

●

●

● |

●

| ●

● ●

| |

| Basic Chimango | Onetsetsani ngati wononga wononga kumapeto kwa chimango olamulira anali kumasula Thiraninso utoto wothira mafuta ngati kuli kofunikira |

●

|

●

|

●

|

● |

| Mphamvu Perekani | Dinani batani loyesa lachitetezo cha dera kuti muwone ngati woteteza dera akugwira ntchito bwino Onani ngati chingwecho chidasweka | ● ● |

● |