TPWG315 380 DIGITAL PRESSURE GAUGE

Mwachidule

Pamodzi ndi katundu wa PE zinthu mosalekeza ungwiro ndi kulera, PE chitoliro ntchito kwambiri gasi ndi madzi, kutaya zimbudzi, makampani mankhwala, mgodi ndi zina zotero.

Fakitale yathu yakhala ikufufuza ndikupanga makina ophatikizira a TPW apulasitiki omwe ndi oyenerera PE, PP, ndi PVDF kwazaka zopitilira khumi.

Masiku ano, zogulitsa zathu zikuphatikiza mitundu isanu ndi itatu komanso yopitilira 20 yomwe imagwira ntchito pomanga mapaipi apulasitiki ndikupanga zomangira mumisonkhano motere:

| SHS mndandanda socket welder | TPWC Series Band saw |

| TPW mndandanda wa makina ophatikizira matako | TPWG mndandanda makina kuwotcherera mndandanda |

| TPWY mndandanda wa makina ophatikizira matako | Series zida zapadera |

| QZD mndandanda Auto-butt fusion makina | SHM mndandanda makina ophatikizira chishalo |

Bukuli ndi la TPWG315 pulasitiki chitoliro msonkhano kuwotcherera makina. Pofuna kupewa ngozi yamtundu uliwonse chifukwa cha magetsi kapena makina. Ndibwino kuti muwerenge mosamala ndikutsatira malamulo otsatirawa achitetezo musanagwiritse ntchito makinawo.

Kufotokozera Kwapadera

Asanagwiritse ntchito makinawo, aliyense ayenera kuwerenga malongosoledwe awa mosamala ndikusunga bwino kuti atsimikizire chitetezo cha makinawo komanso chitetezo cha ena.

2.1 Makinawa amagwiritsidwa ntchito kuwotcherera mapaipi opangidwa kuchokera ku PE, PP, PVDF ndipo sangagwiritsidwe ntchito kuwotcherera zinthu popanda kufotokozera, apo ayi makinawo akhoza kuonongeka kapena ngozi ina ingachitike.

2.2 Osagwiritsa ntchito makina pamalo omwe atha kuphulika

2.3 Makinawa ayenera kuyendetsedwa ndi ogwira ntchito, oyenerera komanso ophunzitsidwa bwino.

2.4 Makinawa azigwiritsidwa ntchito pamalo owuma. Njira zodzitetezera ziyenera kutengedwa ngati zikugwiritsidwa ntchito pamvula kapena pamtunda wonyowa.

2.5 Makinawa amafunikira 380V ± 10%, 50 Hz magetsi. Ngati chingwe chowonjezera chiyenera kugwiritsidwa ntchito, payenera kukhala gawo lokwanira malinga ndi kutalika kwake.

Chitetezo

3.1 zizindikiro zachitetezo

Zizindikiro zotsatirazi zimayikidwa pamakina:

3.2 Kusamala pa Chitetezo

Samalani mukamagwiritsa ntchito ndikunyamula makinawo molingana ndi malamulo onse otetezedwa mu malangizowa.

3.2.1 Zindikirani mukamagwiritsa ntchito

l Wogwira ntchitoyo ayenera kukhala wodalirika komanso wophunzitsidwa bwino.

l Yang'anani kwathunthu ndikusamalira makinawo pachaka chifukwa cha chitetezo ndi makina

kudalirika.

3.2.2Mphamvu

Bokosi logawa magetsi liyenera kukhala ndi chosokoneza chapansi chokhala ndi muyezo woyenera wachitetezo chamagetsi. Zida zonse zotetezera chitetezo zimawonetsedwa ndi mawu osavuta kumva kapena zilembo.

3.2.3 Zimitsani magetsi musanachotse chophimba kapena neti.

Kulumikizana kwa makina ndi mphamvu

Makina olumikizira chingwe ku mphamvu akuyenera kukhala kugwedezeka kwamakina ndi umboni wa dzimbiri. Ngati waya wotalikirapo wagwiritsidwa ntchito, uyenera kukhala ndi gawo lotsogolera lokwanira molingana ndi kutalika kwake.

Earthing: Tsamba lonse liyenera kugawana waya wapansi womwewo ndipo njira yolumikizira pansi iyenera kumalizidwa ndikuyesedwa ndi akatswiri.

3.2.3Kusungirako zida zamagetsi

Za min. Zowopsa, zida zonse ziyenera kugwiritsidwa ntchito ndikusungidwa moyenera motere:

※ Pewani kugwiritsa ntchito mawaya osakhalitsa osatsatira muyezo

※ Osakhudza mbali za electrophorus

※ Letsani kutulutsa chingwe kuti muchotse

※ Letsani zingwe zonyamulira zida

※ Osayika chinthu cholemera kapena chakuthwa pazingwe, ndikuwongolera kutentha kwa chingwe mkati mwa kuchepetsa kutentha (70 ℃)

※ Osagwira ntchito m'malo amvula. Onani ngati poyambira ndi nsapato zauma.

※ Osawaza makina

3.2.4 Yang'anani momwe makinawo alili nthawi ndi nthawi

※ Yang'anani kusungunula kwa zingwe makamaka mfundo zomwe zatulutsidwa

※ Osagwiritsa ntchito makinawo ali ovuta kwambiri.

※ Onani ngati chosinthira chotsitsa chimagwira ntchito bwino osachepera pa sabata.

※ Yang'anani momwe makinawo amagwirira ntchito ndi anthu oyenerera

3.2.5 Yeretsani ndikuwunika makinawo mosamala

※ Osagwiritsa ntchito zinthu (monga abrasive, ndi zosungunulira zina) kuwononga zotsekemera mosavuta poyeretsa makina.

※ Onetsetsani kuti mphamvu yatsekedwa mukamaliza ntchito.

※ Onetsetsani kuti palibe kuwonongeka kulikonse mu makina musanagwiritsenso ntchito.

Ngati mutatsatira zomwe tatchulazi, kusamala kungagwire ntchito bwino.

3.2.6 Kuyambira

Onetsetsani ngati chosinthira cha makina chatsekedwa musanayatse.

3.2.7 Kulimba kwa magawo

Onetsetsani kuti mapaipi akhazikika bwino. Onetsetsani kuti imatha kuyenda bwino ndikuyiteteza kuti isagwere pansi.

3.2.8 Malo ogwirira ntchito

Pewani kugwiritsa ntchito makina m'malo odzaza utoto, gasi, utsi ndi deoil, chifukwa matenda am'maso ndi kupuma angayambitsidwe.

Osayika makinawo pamalo akuda.

3.2.9 Chitetezo cha anthu pakugwira ntchito

Chotsani zodzikongoletsera ndi mphete, ndipo musavale zovala zotayirira pewani kuvala zingwe za nsapato, masharubu aatali kapena tsitsi lalitali lomwe lingakokedwe mumakina.

3.3 Chitetezo cha Zida

Makina owotcherera a Hydraulic workshop amangoyendetsedwa ndi katswiri kapena wogwira ntchito yemwe ali ndi satifiketi yophunzitsidwa bwino. Munthu wamba akhoza kuwononga makina kapena ena pafupi.

3.3.1 Chotenthetsera mbale

l Kutentha kwapamwamba kwa mbale yotenthetsera kumatha kufika 270 ℃. Osaikhudza mwachindunji kuti musawotchedwe

l Musanagwiritse ntchito komanso mukamaliza, yeretsani pamwamba ndi nsalu yofewa. Pewani zinthu zowononga zomwe zingawononge zokutira.

l Yang'anani chingwe chotenthetsera mbale ndikutsimikizira kutentha kwapamwamba.

3.3.2 Chida chokonzekera

l Musanamete mapaipi, malekezero a mapaipi ayenera kutsukidwa, makamaka kuyeretsa mchenga kapena nsonga zina zomwe zimalira mozungulira. Pochita izi, moyo wa m'mphepete ukhoza kukhala wautali, komanso kuteteza kumeta kutayidwa kwa anthu oopsa.

l Tsimikizirani chida chopangira chotseka mwamphamvu ndi malekezero awiri a chitoliro

3.3.3 Mainframe:

l Onetsetsani kuti mapaipi kapena zokometsera zakhazikika bwino kuti zigwirizane bwino.

l Pojowina mapaipi, wogwiritsa ntchito ayenera kusunga malo ena ku makina kuti ateteze anthu.

l Musananyamule, onetsetsani kuti zingwe zonse zakhazikika bwino ndipo sizingagwere panthawi yoyendetsa.

Ntchito Range And Technical Parameters

| Mtundu | Chithunzi cha TPWG315 | |

| Zipangizo zowotcherera | PE, PP, PVDF | |

| Kunja Diameter osiyanasiyana | chigongono (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm |

| pansi (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| mtanda (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Wyes 45 ° & 60 ° (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Kutentha kwa chilengedwe | ℃ 5 ~ 45 ℃ | |

| Mafuta a Hydraulic | 40 ~ 50 (kinematic viscosity) mm2/s, 40℃) | |

| Magetsi | ~380V±10% | |

| pafupipafupi | 50hz pa | |

| Total panopa | 13 A | |

| Mphamvu zonse | 7.4 kW | |

| Kuphatikizapo, Kutentha mbale | 5.15 kW | |

| Makina opangira zida | 1.5 kW | |

| Hydraulic unit motor | 0.75 kW | |

| Insulating resistance | > 1M | |

| Max. kuthamanga kwa hydraulic | 6 MPpa | |

| Chigawo chonse cha masilinda | 12.56 cm2 | |

| Max. kutentha kwa kutentha mbale | 270 ℃ | |

| Kusiyanasiyana kwa kutentha kwapamwamba kwa mbale yotentha | ± 7℃ | |

| Phokoso losafunidwa | <70 dB | |

| Voliyumu ya tank ya mafuta | 55l ndi | |

| Kulemera konse(kg) | 995 | |

Kufotokozera

Makina owotcherera a msonkhano amatha kupanga chigongono, tee, kuwoloka ndi chitoliro cha PE pamsonkhano. Zomangamanga zokhazikika zimagwirizana ndi kukula kwa mapaipi malinga ndi ISO161/1.

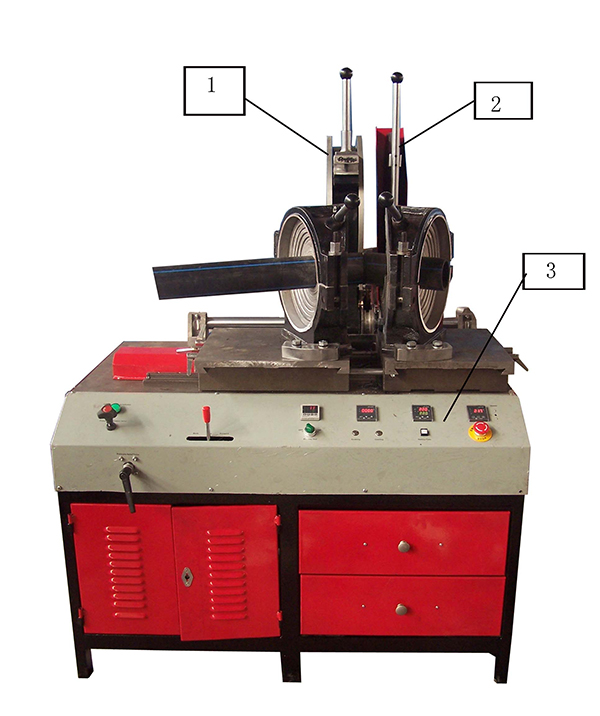

5.1 Makina akulu

| 1. Chida chokonzekera | 2. Kutentha mbale | 3. Gulu la ntchito |

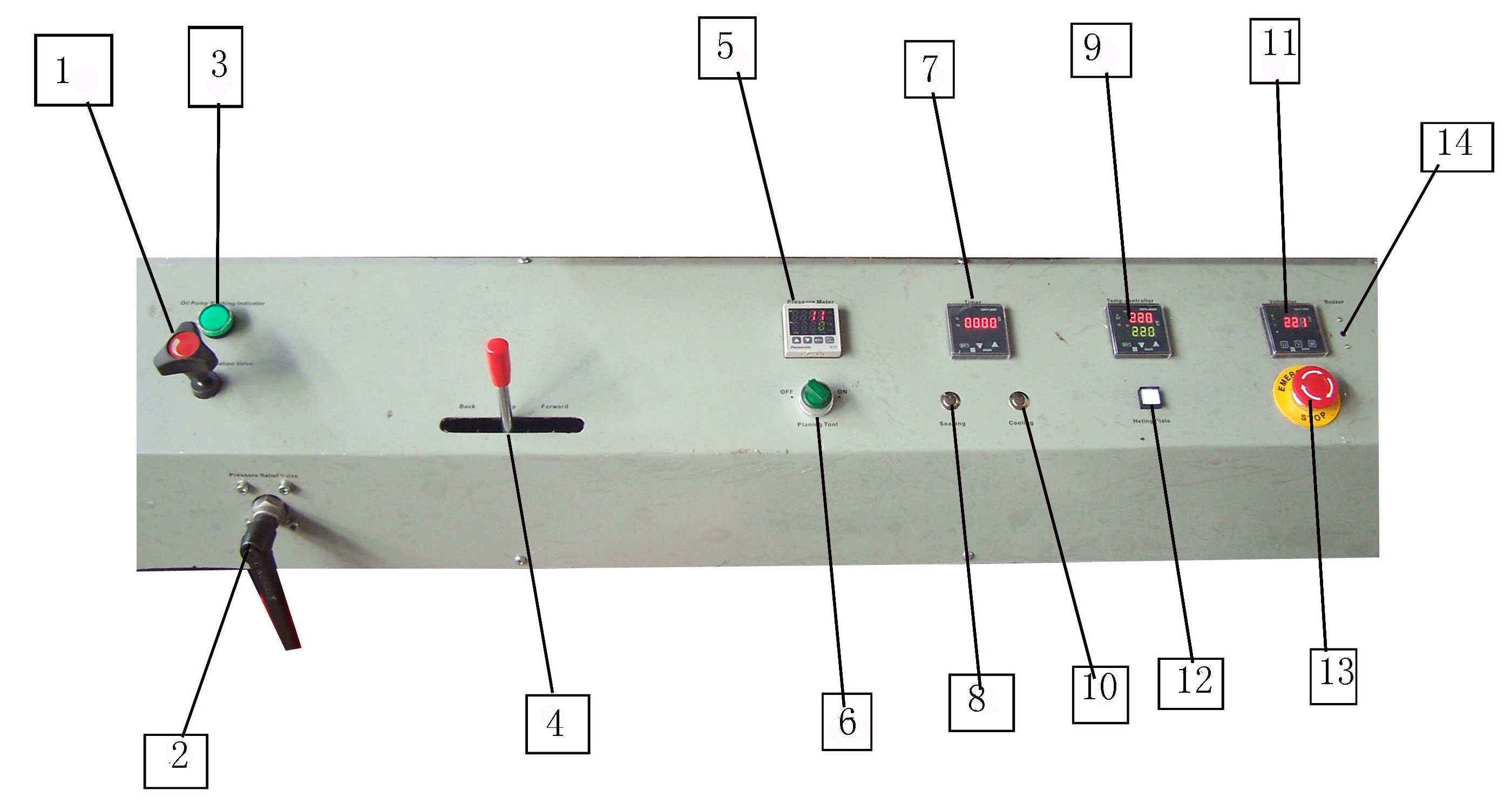

5.2 Gulu la ntchito

| 1. Valve ya Pressure Regulation | 2. Vavu Yothandizira Kupanikizika | 3. Mafuta Pampu Ntchito Indicator | 4. Vavu yolowera |

| 5. Digital Pressure Meter | 6. Batani Lokonzekera | 7. Chowerengera nthawi | 8. Kuwukha Nthawi Batani |

| 9. Temperature Control Meter | 10. Kuzizira Time Button | 11. Voltmeter | 12. Kusintha kwa Kutentha |

| 13. Imani Mwadzidzidzi | 14. Buzzer |

Kuyika

6.1 Kukweza ndi kukhazikitsa

Mukakweza ndikuyika makinawo ayenera kukhala opingasa, osakhomerera kapena kuyisintha kuti isawonongeke.

6.1.1 Ngati forklift ikugwiritsidwa ntchito, iyenera kuyikidwa mosamala kuchokera pansi pa makina mosamala kuti asawononge payipi yamafuta ndi dera.

6.1.2 Mukatumiza makinawo kumalo oyika, mainframe iyenera kukhala yokhazikika komanso yopingasa.

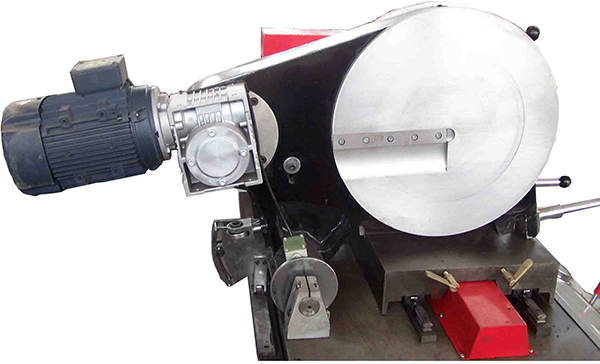

6.1.3 Ikani injini ku bokosi lochepetsera la chida chokonzekera ndikukhazikika ndi zomangira, zomwe zikuwonetsedwa mu Mkuyu .3.

6.2 Mgwirizano

Onetsetsani kuti malowa ndi okwanira kuyika makinawo ndikusunga makina onse opingasa ndikutsimikizira kulumikizana koyenera kwa sockets, zingwe ndi mapaipi poyika makinawo.

6.2.1 Lumikizani makina akuluakulu ku bokosi lamagetsi.

Chithunzi cha 4 Lumikizani mbale yotenthetsera ku bokosi lamagetsi

Chithunzi 5 Lumikizani chida chokonzekera ku bokosi lamagetsi

6.2.2 Kulumikiza chingwe cha makina ku mphamvu, yomwe ili magawo atatu- mawaya asanu 380V 50HZ.

Kuti mutetezeke, makinawo ayenera kuyikidwa pansi kuchokera pansi pa makinawo.

6.2.3 Dzazani mafuta osefedwa a hydraulic. Kutalika kwa mafuta kuyenera kukhala 2/3 kutalika kwa kuchuluka kwa zomwe zili.

Chenjezo: Kuyika pansi kuyenera kumalizidwa ndi akatswiri.

Malangizo Ogwiritsa Ntchito

Tsatirani malamulo onse otetezedwa pamakina. Munthu wosaphunzitsidwa saloledwa kugwiritsa ntchito makinawo.

7.1 Mphamvu

Tsekani chosokoneza chapansi

7.2 Yambani pompa mafuta

Yambitsani mpope wamafuta kuti muwone komwe akuzungulira. Ngati chiwongola dzanja chili ndi zowerengera, kuzungulira kuli koyenera, ngati sichoncho, sinthani mawaya awiri amoyo.

7.3 Yang'anani ndikusintha kuthamanga kwa kukoka ndikusuntha liwiro la mbale yokoka. Kupanikizika kwa dongosololi ndi 6 MPa. Kuphatikizika kophatikizana kumatha kusinthidwa ndi valavu yowongolera kuthamanga yomwe ili pagawo lowongolera. Kupsyinjika kwa planing kuyenera kuchulukitsidwa pang'onopang'ono, ndikusunga pamene kumeta kosalekeza kumawoneka (osati kwakukulu kwambiri). Kuthamanga kwa chakudya cha mbale yokoka kumatha kusinthidwa kudzera mu valavu yoyendera (mkati mwa maziko).

7.4 Kuyika kwa Clamp

Ikani mipando yotsekera kumanzere ndi kumanja (zotsekera zamasewera kapena zigongono) molingana ndi zomangira zomwe zikuyenera kupangidwa.

1) Akonzeni poyamba ndi pini ya loko yolumikizidwa ndi makina;

2) Sinthani ngodya ndi chogwirira chapadera;

3) Limbani wononga loko ndi wrench.

Ngati zigongono zikufunika kugwiritsidwa ntchito, zisindikize mwamphamvu ndi loko mutatha kusintha ngodyayo.

7.5 Khazikitsani kutentha kwapadera pa chowongolera kutentha malinga ndi njira yowotcherera chitoliro. (Onani ndime 7.10)

7.6 Musanakweze kapena kutsitsa chida cholozera, tsegulani chotsekera pa chogwirira.

7.7 Mapaipi akuyika mu makina

7.7.1 Alekanitse zingwe zamakina pochita pa lever ya valavu yolowera

7.7.2 Ikani mapaipi mu zomangira ndi kuzimanga; danga pakati pa malekezero awiri chitoliro ayenera kukhala zokwanira planing chida.

7.7.3 Valavu yotsekera yotsekera, potseka malekezero awiri, tembenuzirani valavu yowongolera kupanikizika mpaka mphamvu yamagetsi ikuwonetsa kuthamanga kwa fusion, komwe kumatsimikiziridwa ndi zida zapaipi.

7.8 Kupanga

7.8.1 Alekanitse zipikazo pochita valavu yolowera ndi valavu yotseguka yotsegulira.

7.8.2 Ikani chida chokonzekera pakati pa malekezero awiri ndi kuyatsa, kuyandikira mapaipi kumapeto kwa chida chokonzekera pogwiritsa ntchito valavu yotsogolera "kutsogolo", ndikusintha valavu yoyendetsera kuthamanga kuti ikhale yoyenera mpaka kumeta kosalekeza kukuwonekera kuchokera ku ziwirizo. mbali.Zindikirani: 1) Makulidwe a shavings ayenera kukhala mkati mwa 0.2 ~ 0.5mm ndipo akhoza kusinthidwa mwa kusintha kutalika kwa chida chokonzekera.

2) Kupanikizika kokonzekera sikuyenera kupitirira 2.0 MPa kuti mupewe kuwonongeka kwa chida chokonzekera.

7.8.3 Mukatha kukonza, Alekani zikhomo ndikuchotsa chida chokonzekera.

7.8.4 Tsekani mbali ziwirizo kuti mugwirizane nazo. Ngati kusanja kupitirira 10% ya makulidwe a chitoliro, sinthani mwa kumasula kapena kumangitsa zingwe zapamwamba. Ngati kusiyana pakati pa malekezero kupitirira 10% ya makulidwe a khoma la chitoliro, konzekerani chitolirocho mpaka mutapeza zofunikira.

7.9 kuwotcherera

7.9.1 Khazikitsani nthawi yonyowa ndi nthawi yozizirira molingana ndi njira yowotcherera.

7.9.2 Mukachotsa chida chokonzekera, ikani mbale yotenthetsera, Tsekani pang'onopang'ono valavu yothandizira pamene mukukankhira kutsogolo valavu, yomwe imawonjezera kutentha kwa kutentha kwa fusion yomwe yatchulidwa.1). Chitoliro chimatha kumamatira ku mbale yotenthetsera ndipo kuphatikizika kumayamba.

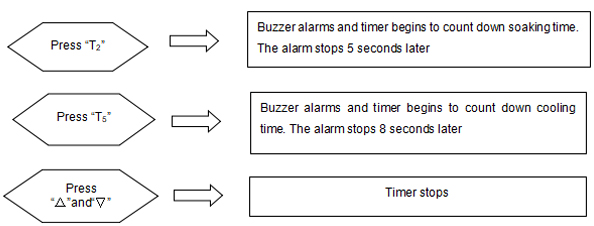

7.9.3 Mkanda wawung'ono ukamanga, kankhirani kumbuyo valavu yolowera pakati kuti musunge kuthamanga. Tembenuzirani swing cheke valavu kuti muchepetse kukakamiza konyowa (P2) ndiyeno nkutseka mwachangu. Kenako dinani batani lotsitsa nthawi yoyambira.

7.9.4 Pambuyo pakuwuka (ma alarm a buzzer), tsegulani zowongolera pochita pa valve yowongolera ndikuchotsa mbale yotentha mwachangu.

7.9.5 Lowani malekezero awiri osungunuka mofulumira ndikusunga valavu yotsogolera pa "forward" kwa nthawi yochepa ndikukankhira kumbuyo ku malo apakati kuti musunge kupanikizika. Panthawiyi, kuwerengera muyeso ya pressure ndi mphamvu ya fusion (ngati sichoncho, isintheni pogwiritsa ntchito valve regulation valve).

7.9.6 Kanikizani pansi batani la nthawi yozizira pamene kuzizirira kukuyamba. Nthawi yoziziritsa ikadutsa, buzzer imachenjeza. Yambitsaninso kupanikizika kwadongosolo pochita ma valve opumira, tsegulani zingwe ndikuchotsa mafupa.

7.9.7 Yang'anani cholumikizira molingana ndi njira zowotcherera.

7.10 Wowongolera kutentha ndi nthawi

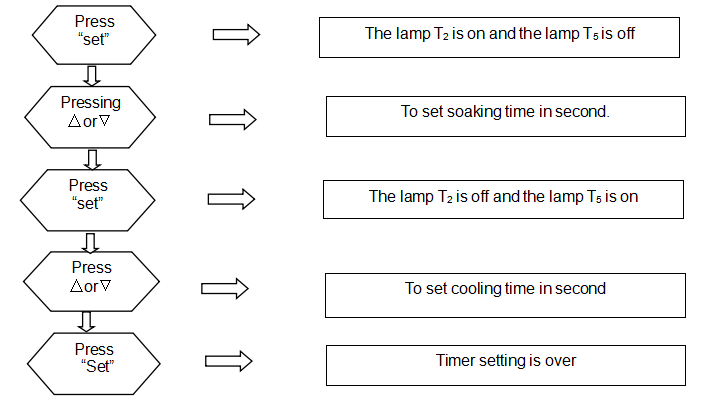

7.10.1 Kukhazikitsa nthawi

7.10 Wowongolera kutentha ndi nthawi

7.10.1 Kukhazikitsa nthawi

7.10.2 Nthawi yogwiritsira ntchito

7.10.3 Kutentha kowongolera kutentha

1) Dinani "SET" kwa masekondi opitilira 3 mpaka "sd" ikuwonetsedwa pazenera lapamwamba

2) Dinani "∧" kapena "∨" kuti musinthe mtengo kukhala kutentha komwe kwatchulidwa (dinani "∧" kapena "∨" mosalekeza, mtengowo udzawonjezera kapena kuchotsa zokha)

3) Mukakhazikitsa, dinani "SET" kuti mubwerere kuwunikira ndi kuyang'anira mawonekedwe

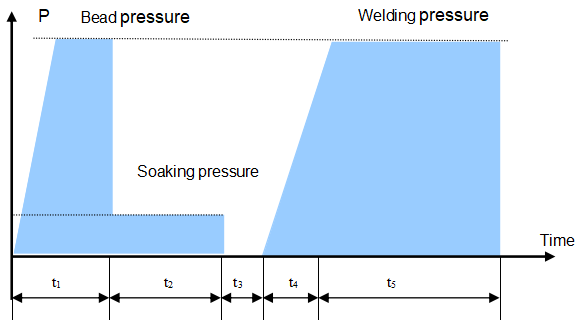

Reference Welding Standard (DVS2207-1-1995)

8.1 Chifukwa cha miyezo yowotcherera yosiyana ndi zida za PE, nthawi ndi kukakamizidwa kwa gawo la maphatikizidwe ndizosiyana. Zikuonetsa kuti t iye magawo owotcherera enieni ayenera kutsimikiziridwa ndi mapaipi ndi zovekera kupanga

8.2 Popeza kuwotcherera kutentha kwa mapaipi opangidwa Pe, PP ndi PVDF ndi ranges DVS muyezo from180 ℃ kuti 270 ℃. Kugwiritsa ntchito kutentha mbale Kutentha ndi mkati 180 ~ 230 ℃, ndi Max ake. kutentha pamwamba kumatha kufika 270 ℃.

8.3 Reference muyezoDVS2207-1-1995

| Khoma makulidwe (mm) | Kutalika kwa mikanda (mm) | Kuthamanga kwa mikanda (MPa) | Kutaya nthawi t2(Sekondi) | Kuthamanga kwamadzi (MPa) | Kusintha - pakapita nthawi t3(mphindikati) | Pressure build-nthawi t4(mphindikati) | Welding pressure (MPa) | Nthawi yozizira t5(mphindi) |

| 0 ~ 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5 ~ 7 | 1.0 | 0.15 | 45; 70 | ≤0.02 | 5; 6 | 5; 6 | 0.15±0.01 | 6; 10 |

| 7; 12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6; 8 | 6; 8 | 0.15±0.01 | 10; 16 |

| 12; 19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8; 10 | 8; 11 | 0.15±0.01 | 16; 24 |

| 19; 26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10; 12 | 11; 14 | 0.15±0.01 | 24; 32 |

| 26; 37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12; 16 | 14; 19 | 0.15±0.01 | 32; 45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16-20 | 19; 25 | 0.15±0.01 | 45-60 |

| 50-70 | 4.0 | 0.15 | 500-700 | ≤0.02 | 20-25 | 25; 35 | 0.15±0.01 | 60-80 |

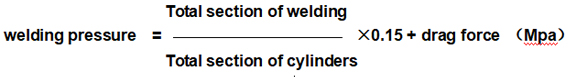

Zindikirani: Kuthamanga kwa mikanda yomanga ndi kuwotcherera mu mawonekedwe ndiko kukakamizidwa kwa mawonekedwe, kuthamanga kwa gauge kuyenera kuwerengedwa motere.

Ndondomeko Yopangira Zopangira

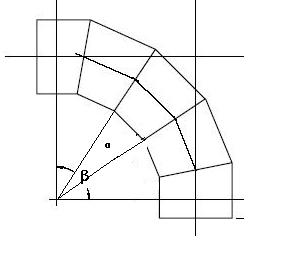

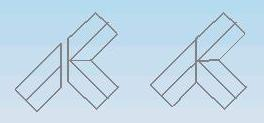

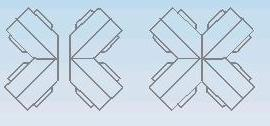

9.1 Kupanga zigongono

9.1.1 Malinga ndi ngodya ya chigongono ndi kuchuluka kwa zigawo zowotcherera, ngodya yowotcherera pakati pa gawo lililonse imatha kusankhidwa.

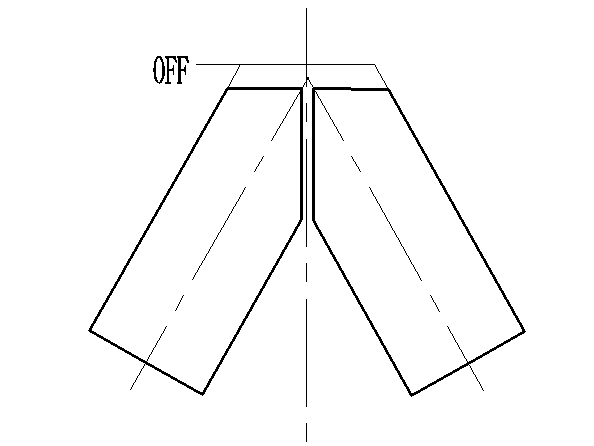

Kufotokozera: α - angle yowotcherera

β - mbali ya chigongono

n - kuchuluka kwa magawo

Mwachitsanzo: 90 ° chigongono chagawidwa m'magawo asanu kuti welded, kuwotcherera ngodya α = β/ (n-1 = 90 ° / (5-1 = 22.5 °)

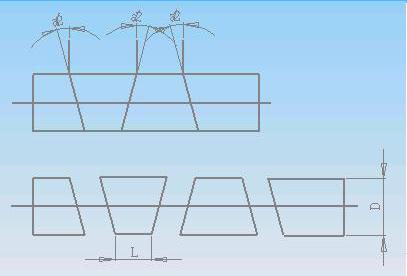

9.1.2 The min dimension ya gawo lililonse lowotcherera mu kuchuluka kwa magawo owotcherera amadulidwa ndi bandeji molingana ndi ngodya.

Kufotokozera:

D - kunja awiri a chitoliro

L - Mphindi kutalika kwa gawo lililonse

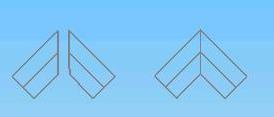

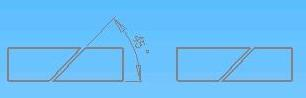

9.2 Ndondomeko yopangira achinyamata

9.2.1 Zipangizo zili ngati chithunzi chotsatirachi:

9.2.2 kuwotcherera monga mawonekedwe azithunzi:

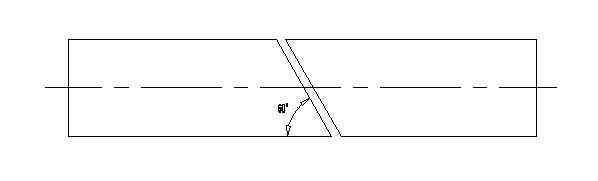

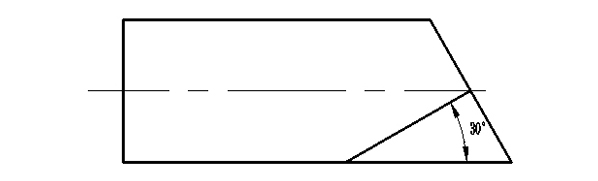

9.2.3 Ngodya imadulidwa ngati chithunzi

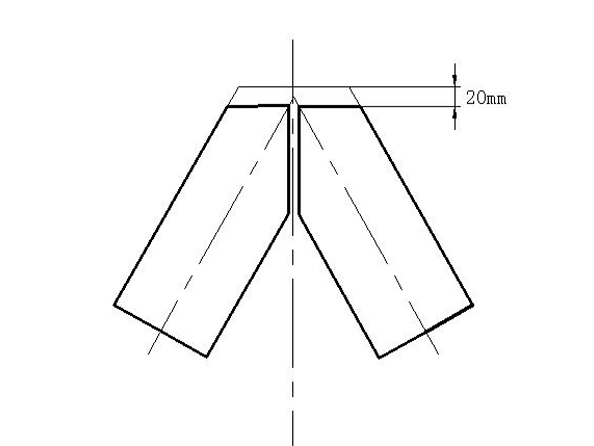

Zindikirani: Makulidwe "a" sayenera kuchepera 20㎜omwe ali ngati malire okonzekera ndikulipira mikanda yosungunuka.

9.2.4 Kuwotcherera monga mawonekedwe azithunzi, ma tee apangidwa.

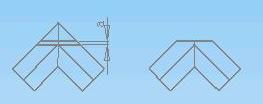

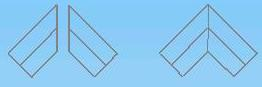

9.3 Ndondomeko yofanana m'mimba mwake mapaipi opangidwa

9.3.1 Zida zimadulidwa monga chithunzi chotsatirachi

9.3.2 Mawiri awiriwa amawotcherera ngati mawonekedwe:

9.3.3 Ngodya imadulidwa ngati chithunzi:

Zindikirani: Makulidwe "a" sayenera kuchepera 20㎜, omwe akukonzekera malire ndikulipira mikanda yosungunuka.

9.3.4 Wowotcherera ngati mawonekedwe azithunzi.

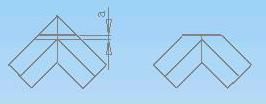

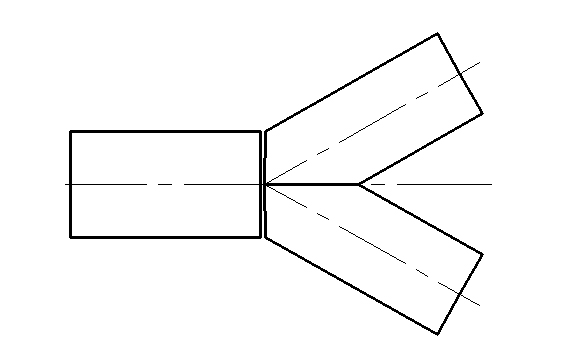

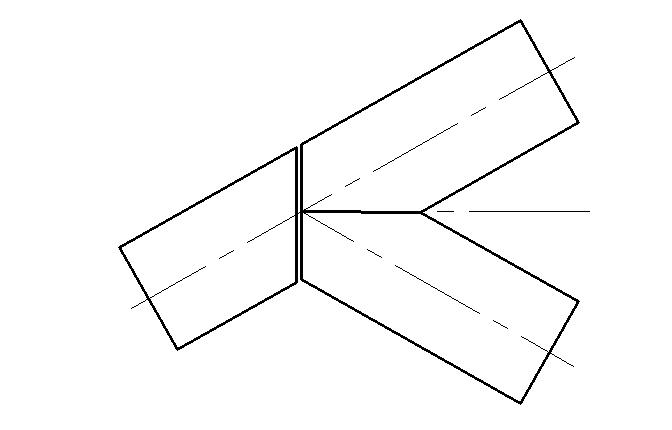

9.4 Njira ya "Y" kupanga zopangira mawonekedwe (45 ° kapena 60 °)

9.4.1 dulani monga chojambula chotsatirachi (tengani 60 ° "Y" mawonekedwe ngati chitsanzo)

9.4.2 Pitirizani ku kuwotcherera koyamba monga zojambula zotsatirazi:

9.4.3 Sinthani zotsekera ndikupitilira kuwotcherera kwachiwiri.

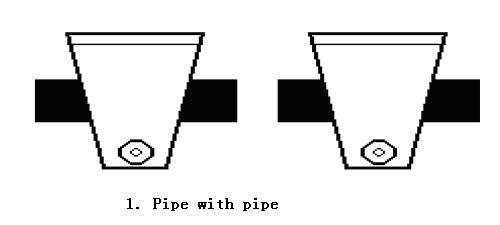

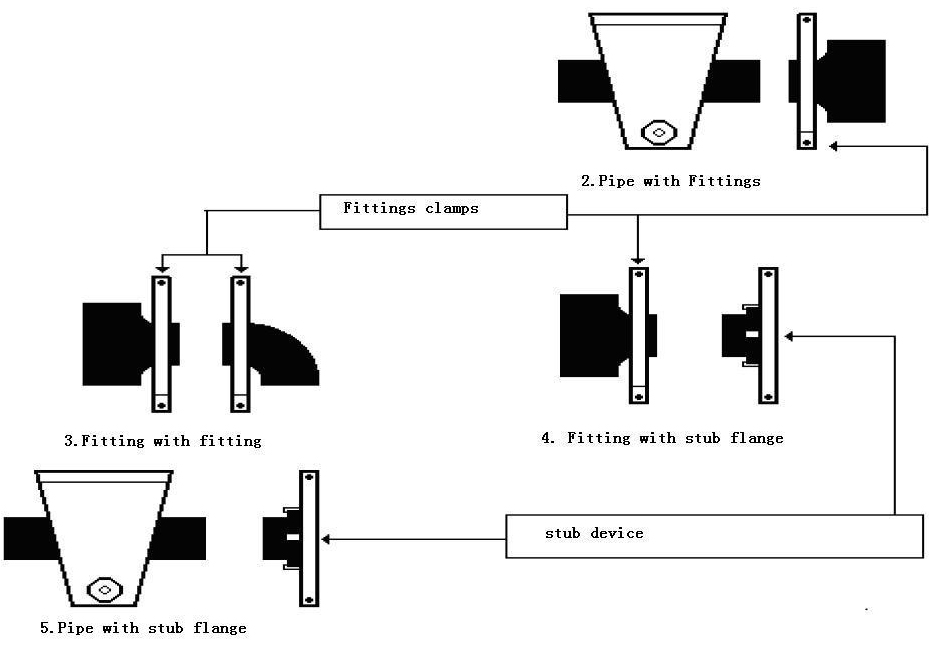

9.5 zolumikizira zina kuwotcherera

9.5.1. Chitoliro ndi chitoliro

9.5.2. Chitoliro chokhala ndi zoyenera

9.5.3 Kuyenerera ndi koyenera

9.5.4 Kuyika ndi stub flange

9.5.5 Chitoliro chokhala ndi stub flange

Kusanthula ndi Kuthetsa Zolakwa

10.1 Kuwunika pafupipafupi zovuta zamalumikizidwe:

10.2 Kusamalira

mu PTFE TACHIMATA Kutentha mbale

Chonde samalani pogwira galasi lotenthetsera kuti mupewe kuwonongeka kwa zokutira za PTFE.

Khalani nthawi zonse kuyeretsa PTFE TACHIMATA pamwamba, kuyeretsa zichitike pamwamba akadali otentha pogwiritsa ntchito nsalu yofewa kapena pepala, kupewa abrasive zipangizo zimene zingawononge PTFE TACHIMATA pamwamba.

Nthawi ndi nthawi, timalimbikitsa:

- Yeretsani pamalopo pogwiritsa ntchito chotsukira chotulutsa madzi mwachangu (mowa)

- Onani kulimba kwa zomangira ndi chingwe ndi pulagi

u Planning chida

Zimalangizidwa kuti nthawi zonse muzitsuka masamba ndikutsuka ma pulleys pogwiritsa ntchito chotsukira.

Nthawi ndi nthawi, gwiritsani ntchito kuyeretsa kwathunthu ndi lubrication yamkati

mu Hydraulic unit

Chigawo cha hydraulic sichifunikira chisamaliro chapadera komabe malangizo awa ayenera kutsatiridwa:

a. Yang'anani nthawi ndi nthawi yopingasa mafuta ndipo ngati muwonjezere ndi mtundu wa mafuta:

Chopingasa sichiyenera kutsika 5 cm kuchokera pa thanki yopingasa kwambiri.

Kuyang'ana masiku 15 aliwonse ogwira ntchito kumalimbikitsidwa.

b. Bwezerani mafutawo miyezi isanu ndi umodzi iliyonse kapena pambuyo pa maola 630 ogwira ntchito.

c. Sungani ma hydraulic unit mosamala kwambiri pa thanki ndi kulumikizana mwachangu.

10.3 Kusanthula kosagwira ntchito pafupipafupi ndi yankho

Pogwiritsa ntchito, ma hydraulic unit ndi magetsi amatha kuwoneka ngati zovuta. Kulephera kugwira ntchito pafupipafupi kumatchulidwa motere:

Chonde gwiritsani ntchito zida zolumikizidwa, zotsalira kapena zida zina zokhala ndi satifiketi yachitetezo pokonza kapena kusintha zina. Zida ndi zida zosinthira zopanda satifiketi yachitetezo ndizoletsedwa kugwiritsidwa ntchito.

| Kuwonongeka kwa hydraulic unit | |||||

| No | wonongeka | amasanthula | zothetsera | ||

| 1 | Galimoto sikugwira ntchito |

wamasulidwa

| |||

| 2 | Galimoto imazungulira pang'onopang'ono ndi phokoso lachilendo |

| pa 3 MPa

| ||

| 3 | Silinda imagwira ntchito mwachilendo |

wotsekedwa mwamphamvu

| kutulutsa mpweya. | ||

| 4 | Kukoka mbale yosuntha silinda sikugwira ntchito |

valavu yatsekedwa |

valve yowonjezera (1.5 MPa ndiyoyenera).

| ||

| 5 | Kutsika kwa cylinder | 1. Mphete yamafuta ndi yolakwika2. Silinda kapena pistoni ndiyowonongeka kwambiri | 1. Bwezerani mphete yamafuta2. Bwezerani yamphamvu | ||

| 6 | Kupanikizika sikungawonjezeke kapena kusinthasintha kuli kwakukulu kwambiri | 1. Pakatikati pa valavu yowonongeka ndi yotsekedwa.2. Pampu yatha.3. Kutsetsereka kolumikizana kwa pampu kumasulidwa kapena poyambira makiyi ndi skid. | 1. Yeretsani kapena sinthani valavu yapakati pa madzi osefukira2. Bwezerani pampu yamafuta3. Bwezerani m'malo olowa | ||

| 7 | Kudula kuthamanga sikungasinthidwe | 1. Dera ndilolakwika2. Koyilo yamagetsi ndi yolakwika3. Valavu yakusefukira yatsekedwa4. Kudula valavu yakusefukira sikwachilendo | 1. Yang'anani kuzungulira (diodein yofiyira koyilo yamagetsi imawala)2. Sinthani koyilo yamagetsi yamagetsi3. Yeretsani pakati pa valavu yotuluka 4. Yang'anani valavu yodula kwambiri | ||

| Kuwonongeka kwa magawo amagetsi | |||||

| 8 | Makina onse sagwira ntchito |

| 1. Yang'anani chingwe chamagetsi2. Onani mphamvu yogwira ntchito3. Tsegulani chosokoneza chapansi | ||

| 9 | Maulendo osinthira zolakwika zapansi |

| 1. Onani zingwe zamagetsi2. Onani zinthu zamagetsi.3. Yang'anani chipangizo champhamvu chachitetezo chapamwamba | ||

| 10 | Kutentha kwachilendo kumawonjezeka |

4. 4. Kuwerengera kowongolera kutentha kuyenera kukhala kopitilira 300 ℃, zomwe zikuwonetsa kuti sensa ikhoza kuonongeka kapena kulumikizana kwamasuka. Wowongolera kutentha akuyenera kuwonetsa LL, zomwe zikuwonetsa kuti sensayo ili ndi dera lalifupi. Wowongolera kutentha akuyenera kuwonetsa HH, zomwe zikuwonetsa kuti sensor yozungulira ndi yotseguka. 5. Konzani kutentha ndi batani lomwe lili pa chowongolera kutentha.

| zolumikizira

wowongolera

ikani kutentha

contactors ngati pakufunika | ||

| 11 | Kutaya mphamvu pakuwotha | Kuwala kofiira kumawala, koma kutentha kumakwerabe, chifukwa cholumikizira ndi cholakwika kapena zolumikizira 7 ndi 8 sizingatseguke zikafika kutentha kofunikira. | Bwezerani chowongolera kutentha | ||

| 12 | Chida chokonzekera sichizungulira | Kusintha kwa malire sikukugwira ntchito kapena zida zamakina zamakina zimadulidwa. | Bwezerani malire a zida zokonzekera kusintha kapena sprocket yaying'ono | ||

Circuit & Hydraulic Unit Diagram

11.1 Chiwonetsero cha gawo lozungulira (chomwe chikuwonetsedwa mu appendix)

11.2 Chithunzi cha hydraulic unit (chowoneka mu appendix)

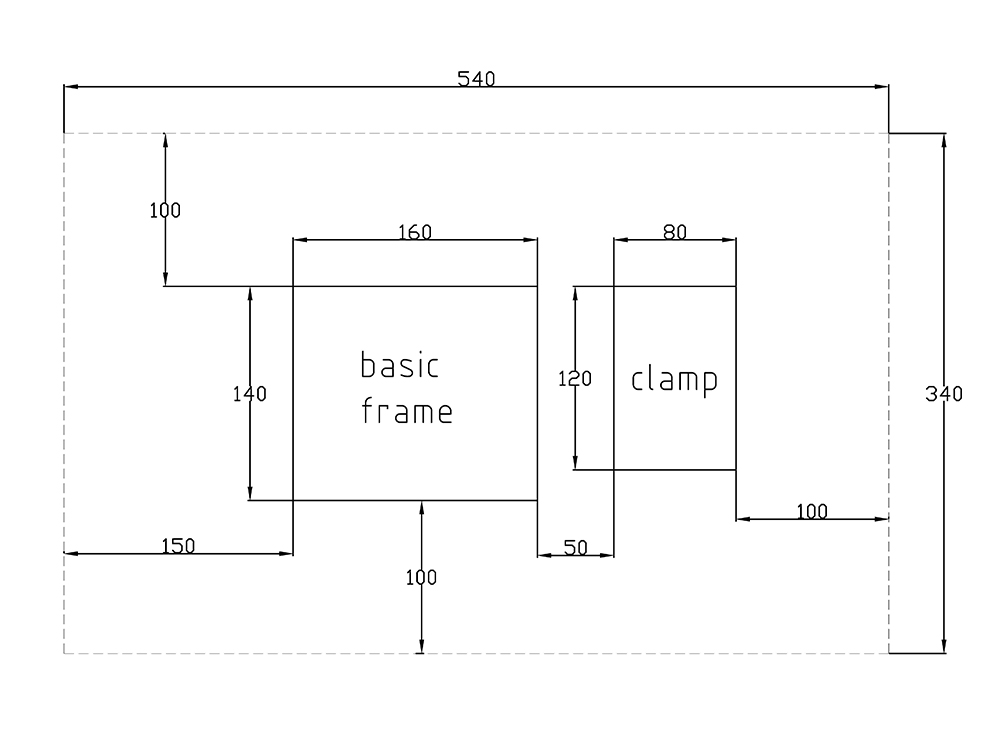

Tchati cha Space Occupation