TPWC315 BAND SAW OPERATION MANUAL

Kufotokozera Kwapadera

Asanagwiritse ntchito makinawo, aliyense ayenera kuwerenga malongosoledwe awa mosamala ndikusunga bwino kuti atsimikizire chitetezo cha makinawo komanso chitetezo cha ena.

2.1 Makinawa amagwiritsidwa ntchito podula mapaipi opangidwa kuchokera ku PE, PP ndi PVDF ndipo sangagwiritsidwe ntchito podula zipangizo zosafotokozera; apo ayi makinawo akhoza kuwonongeka kapena kuchititsa ngozi.

2.2 Osagwiritsa ntchito makina pamalo omwe atha kuphulika

2.3 Makinawa ayenera kuyendetsedwa ndi ogwira ntchito, oyenerera komanso ophunzitsidwa bwino.

2.4 Makinawa azigwiritsidwa ntchito pamalo owuma. Njira zodzitetezera ziyenera kutengedwa ngati zikugwiritsidwa ntchito pamvula kapena pamtunda wonyowa.

2.5 Mphamvu yolowera ili mkati mwa 380V±10%, 50Hz. Ngati mzere wowonjezera wowonjezera ukugwiritsidwa ntchito, mzerewo uyenera kukhala ndi gawo lotsogolera lokwanira.

2.6 Dzazani mafuta a hydraulic (N46 ISO3448) mu thanki musanagwiritse ntchito koyamba. Kuchuluka kwa mafuta kuyenera kukhala pafupifupi 2/3 ya thanki.

Chitetezo

Zizindikiro zotsatirazi zimayikidwa pamakina.

3.2. Kusamala kwa Chitetezo

Mukamagwiritsa ntchito makinawo, malangizo ndi chitetezo ziyenera kutsatiridwa mosamala.

3.2.1 Wogwiritsa ntchitoyo ayenera kukhala ophunzitsidwa bwino komanso aluso.

3.2.2 Yang'anani kwathunthu ndikusamalira makinawo pachaka chifukwa cha chitetezo ndi kudalirika kwa makina.

3.2.3 Mphamvu: bokosi logawa magetsi liyenera kukhala ndi chosokoneza pansi ndi muyezo woyenera wachitetezo chamagetsi.

Earthing: Tsamba lonse liyenera kugawana waya wapansi womwewo ndipo njira yolumikizira pansi iyenera kumalizidwa ndikuyesedwa ndi akatswiri.

3.2.4 Kusungirako makina:

Pazowopsa zazing'ono zida zonse ziyenera kugwiritsidwa ntchito motere:

※ Osakhudza mbali za electrophorus

※ Letsani kutulutsa chingwe kuti muchotse

※ Osayika chinthu cholemera kapena chakuthwa pazingwe, ndikuwongolera kutentha kwa chingwe mkati mwa kuchepetsa kutentha (70 ℃)

※ Osagwira ntchito m'malo amvula. Onani ngati poyambira ndi nsapato zauma.

※ Osawaza makina

3.2.5 Yang'anani momwe makinawo alili nthawi ndi nthawi

※ Yang'anani kusungunula kwa zingwe makamaka mfundo zomwe zatulutsidwa

※ Osagwiritsa ntchito makinawo ali ovuta kwambiri.

※ Onani ngati chosokoneza chapansi chimagwira ntchito bwino mwezi uliwonse.

※ Yang'anani momwe makinawo amagwirira ntchito ndi anthu oyenerera

3.2.6 Yeretsani makina mosamala

※ Osagwiritsa ntchito zinthu zomwe zimawononga kutsekeka mosavuta (monga gasi, abrasive, ndi zosungunulira zina)

※ Mphamvu iyenera kuchotsedwa mukamaliza ntchito.

Ngati mutatsatira zomwe tatchulazi, kusamala kungagwire ntchito bwino.

3.2.7KUYAMBIRA KWAMBIRI

Zilizonse zosayembekezereka zikachitika, chonde dinani "EMERGENCY STOP" nthawi yomweyo kuti muyimitse makinawo. Mukatha kuthetsa mavuto tembenuzirani EMERGENCY STOP molunjika kuti muyambitsenso makina.

3.2.8 Kulimba kwa magawo:Yang'anani ngati mapaipi akhazikika bwino komanso mwamphamvu. Onetsetsani kuti sichikhoza kutsika kwa wovulalayo

3.2.9 Ogwira ntchitochitetezo pamene ntchito

Chotsani zodzikongoletsera ndi mphete, ndipo musavale zovala zotayirira pewani kuvala zingwe za nsapato, masharubu aatali kapena tsitsi lalitali lomwe lingakokedwe mumakina.

3.2.10Sungani malo aukhondoy

Khamu la anthu, zauve komanso zamatope siziyenera kugwira ntchito, choncho ndikofunikira kuti malowa azikhala aukhondo komanso aukhondo.

3.2.11 Munthu wosaphunzitsidwa sayenera kuloledwa kugwiritsa ntchito makinawo nthawi iliyonse.

3.3 Zowopsa Zomwe Zingatheke

3.3.1 Band saw

Makinawa amangogwiritsidwa ntchito ndi akatswiri kapena anthu ophunzitsidwa bwino, apo ayi ngozi yapathengo ikhoza kuchitika.

3.3.2 Tsamba la Macheka

Musakhudze tsamba la macheka, kapena kuvulala kungayambitse

3.3.3 Kudula

Musanadule, yeretsani mchenga kunja kwa mapaipi kapena zokokera zina zomwe zalira m'mipope ponyamula. Izi zitha kupewa kuwonongeka kosafunikira kwa tsamba la macheka kapena ngozi zina

Ntchito Range Ndi Technical Parameter

| Mtundu | TPWC-315 |

| Zipangizo zodulira | PA, PP, PVDF |

| Max. Kudula mphamvu | 315 mm |

| Kudula ngodya | 0°~67.5° |

| Kusalondola kwa ngodya | ≤1 ° |

| Kuthamanga kwa mzere wa tsamba la macheka | 230m/mphindi |

| Kutentha kwa chilengedwe | -5~45℃ |

| Magetsi | ~380V±10% |

| pafupipafupi | 50hz pa |

| Total panopa | 5A |

| Mphamvu zonse | 3.7 kW |

| Magalimoto Oyendetsa | 2.2 kW |

| Hydraulic unit motor | 1.5 kW |

| Insulation resistance | > 1M |

| Max. kuthamanga kwa hydraulic | 6 MPpa |

| Kulemera konse (kg) | 1100 |

Kufotokozera

Chowonadi cha bandi chingagwiritsidwe ntchito kudula mapaipi a PE molingana ndi ngodya yoyika popanga chigongono, tee ndi mtanda, kuti makinawo azikhala ndi magwiridwe antchito apamwamba komanso kugwiritsa ntchito zida.

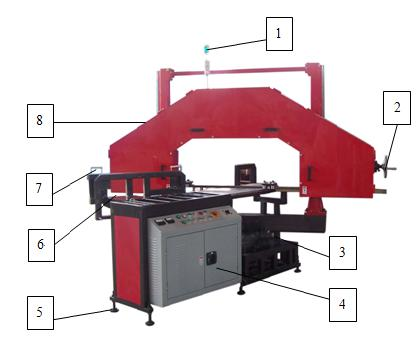

5.1 Kufotokozera za magawo

| 1. chipangizo chochenjeza | 2. gudumu lamphamvu | 3.angle sikelo | 4. bokosi lolamulira |

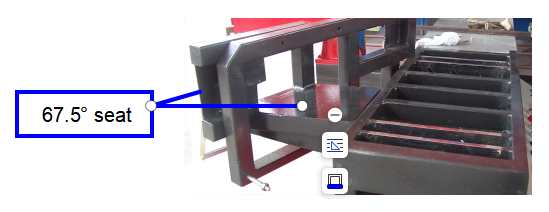

| 5. mlingo chosinthira | 6. 67.5 ° mpando | 7. kukonza chipangizo | 8.mawona bokosi |

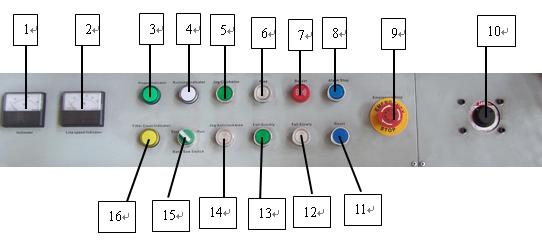

5.2 Gulu la ntchito

| 1. Voltmeter | 2. Line Speed Indicator | 3. chizindikiro cha mphamvu | 4. Chizindikiro chothamanga |

| 5. Yendani molunjika | 6. Ukani | 7. Buzzer | 8. Kuyimitsa ma alarm |

| 9. Kuyimitsa mwadzidzidzi | 10.Feed speed adjustor | 11. Bwezeraninso | 12. Kugwa pang'onopang'ono |

| 13. Igwani msanga | 14. Jog anti molunjika | 15. Band saw switch | 16. mafuta mpope ntchito chizindikiro |

Kuyika

6.1 Kukweza ndi kukhazikitsa

6.1.1 Ngati forklift ikugwiritsidwa ntchito poika, ikani foloko mosamala kuchokera pansi pa makina kuti musawononge payipi yamafuta kapena dera.

6.1.2 Poyika makinawo, makinawo ayenera kukhala okhazikika komanso osasunthika posintha kusintha kwa mlingo.

6.1.3 Makinawa amatha kudula ngodya 0 ~ 67.5 °, ngati ngodya mkati mwa 45 ° ikufunika, mpando wa 67.5 ° uyenera kuchotsedwa musanagwire ntchito.

Ntchito

7.1 Kuyambira

7.1.1 Yambitsani makinawo, ndipo chizindikiro cha mphamvu chiyenera kukhala (ngati sichiyatsidwa, kugwirizana kuli kolakwika).

7.2 Kuyesa kwa bokosi la macheka likuyenda mmwamba ndi pansi potembenuza chosinthira liwiro la chakudya kumanja kwa gulu la opareshoni.

7.3 Dinani batani la "jog clockwise" ndi "jog anticlockwise" kuti muwone komwe macheka akupita. Ngati izungulira molakwika, sinthani kulumikizana pakati pa mawaya awiri aliwonse omwe amalumikizidwa ndi magetsi.

7.4Kudula ntchito

7.4.1 Masulani sikona yokhoma ngodya, kukankhira bokosi la macheka ndi manja kuti lifike pamakona ofunikira (molingana ndi ngodya yofunikira), ndipo sungani sikona yotsekera.

7.4.2 Kwezani bokosi la macheka mpaka kutalika (lomwe limatsimikiziridwa ndi kukula kwa chitoliro kuti lidulidwe) kuonetsetsa kuti dzino la macheka lili pamwamba pa mapaipi.

7.4.3 Ikani chubu chodulira pa tebulo la ntchito, sinthani malo odulira, ndi kukonza chitoliro ndi lamba wa nayiloni potseka chipangizo.

7.4.4 Yambani tsamba la macheka, pamene tsamba la macheka likukwaniritsa liwiro lodziwika (Chizindikiro chothamanga chidzawala), tembenuzirani liwiro la chakudya kuti mugwetse bokosi la macheka pang'onopang'ono. Liwiro la kugwa liyenera kuyendetsedwa molingana ndi kukula kwa chitoliro ndi makulidwe ake.

7.4.5 Mukamaliza kudula, chonde gwirani chitoliro chodulidwa kuti musatseke nsonga ya macheka.

7.4.6 Dinani batani ladzidzidzi ngati pali vuto lililonse panthawi yodula. Mukatha kuthetsa mavuto tembenuzirani EMERGENCY STOP molunjika kuti muyambitsenso makina.

7.4.7 Tsamba la macheka limayima lokha likafika pamalo ocheperako

7.4. 8 Mukamaliza kudula Chotsani chitoliro chodulidwa ndikudulanso.

7.4. 9 Makina okhazikika awa amatha kudula ngodya 0 ~ 67.5 °, ngati ngodya mkati mwa 45 ° ikufunika, mpando wa 67.5 ° uyenera kuchotsedwa musanagwiritse ntchito mapaipi, akuwonetsedwa motere:

Chenjezo:

1) Yambitsaninso makinawo mu mphindi 30 mutadula mphamvu kuti muteteze chosinthira.

2) Makina onse ayenera kuyikidwa pansi kuti atsimikizire chitetezo

3) Cheke ndi kukonza zida zamagetsi ziyenera kuchitidwa ndi katswiri

Zolakwa Ndi Zothetsera

Chonde gwiritsani ntchito zida zolumikizidwa, zotsalira kapena zida zina zokhala ndi satifiketi yachitetezo pokonza kapena kusintha zina. Zida ndi zida zosinthira zopanda satifiketi yachitetezo ndizoletsedwa kugwiritsidwa ntchito.

Table.1 Kulephera kwa makina

| Kanthu | Kufotokozera | Kusanthula | Zothetsera |

| 1 | Band saw tsamba yapanikizana | 1. Mbali ya mpando wa rotary sichimatsekedwa mwamphamvu. 2. Band saw tsamba si tensioned mwamphamvu. 3. Macheka amathamanga pang'onopang'ono kapena macheka amagwa mofulumira kwambiri | 1. Limbikitsani chipangizo chotsekera ngodya. 2. Yang'anirani zodzigudubuza kuti zigwirizane ndi tsamba la macheka. 3. Tsitsani liwiro lakugwa ndikusintha liwiro la mzere wa macheka. |

| 2 | Band saw tsamba madontho | 1. Zogwirizira zamasamba sizinasinthidwe bwino. 2. Band saw tsamba si tensioned. 3. Mawotchi ocheka amamasulidwa. 4. Pakatikati pa valavu yowonongeka ndi yotsekedwa | 1. Kusintha macheka tsamba chofukizira kukonza gulu macheka tsamba mu momwe akadakwanitsira. 2. Sinthani chodzigudubuza cholimba kuti chikanikize tsamba la macheka. 3. Mangirirani mwamphamvu gudumu la macheka. 4. yeretsani pachimake cha valve yosefukira |

Table.2 Zolakwika za Hydraulic system

| Kanthu | Kufotokozera | Zoyambitsa | Zothetsera |

| 1 | Makina a pampu yamafuta sagwira ntchito | 1. Contactor si chatsekedwa 2. Mizere yamkati imachotsedwa 3. Galimoto ndi yolakwika. | 1. Chongani contactor; 2. Onani kugwirizana kapena pulagi. 3. Yang'anani ndi kukonza injini. |

| 2 | Palibe kupanikizika mu dongosolo, ndi phokoso lalikulu mu mpope | 1. Kuzungulira kwa injini yapampu yamafuta sikulondola; 2. Couple ya injini ndi mafuta mpope wachotsedwa 3. Mafuta ndi osakwanira kapena akuda kwambiri. | 1. Iyenera kuzungulira koloko; 2. Onani coupler; 3. Dzazani kapena kusintha mafuta; |

| 3 | Kuthamanga kwa silinda yayikulu ndikofulumira kwambiri kapena pang'onopang'ono | 1. Kupanikizika kwadongosolo ndikwambiri kapena kutsika; 2. Valve ya Throttle imasinthidwa molakwika; 3. Valavu yosinthika ya tsaya imasinthidwa molakwika. | 1. Sinthani dongosolo kuthamanga; 2. Sinthani valavu yotsekemera; 3. Sinthani valavu yolunjika imodzi. |

| 4 | Kupanikizika sikungasinthidwe kukhala kokwezeka kapena kusinthasintha kwamphamvu kumakhala kwakukulu | 1. Chigawo cha valve kusefukira chatsekedwa 2. Fyuluta yamafuta yatsekedwa. 3. Pakatikati pa valve yatsekedwa | 1. Lumikizani & kutsuka kapena sinthani valavu yakusefukira 2. Sambani fyuluta yamafuta. 3 .Disassemble ndi kuyeretsa pachimake valavu kusefukira. |

Circuit & Hydraulic Unit Diagram

9.1 Circuit unit diagram (Malozera ku appendix)

Chithunzi cha 9.2 Hydraulic unit (Zowonjezera)