TPW200 BUTT FUSION MACHINE OPERATION MANUAL

Ntchito Range Ndi Technical Parameter

| Mtundu | Zithunzi za TPWS200 |

| Zipangizo | PE, PP ndi PVDF |

| Kuchuluka kwa diameter × makulidwe | 200mm × 11.76mm |

| Kutentha kozungulira. | -5 ~ 45 ℃ |

| Magetsi | 220V±10%,60Hz |

| Total panopa | 12A |

| Mphamvu zonse | 2.0 kW |

| Kuphatikizanso: mbale yotenthetsera | 1.2 kW |

| Chida chokonzekera | 0.8kw |

| Max. Kutentha | <270 ℃ |

| Kusiyanasiyana kwa kutentha kwapamwamba kwa mbale yotentha | ± 5℃ |

| Max. fusion pressure | 1040N |

| Kulemera konse (kg) | 35kg pa |

Chiyambi cha Makina

Makinawa amakhala ndi chimango choyambira, mbale yotenthetsera, chida chokonzekera ndi chithandizo.

Malangizo Ogwiritsa Ntchito

5.1 Zida zonse ziyenera kuikidwa pa ndege yokhazikika komanso yowuma kuti igwire ntchito.

5.2 Musanachite opaleshoni onetsetsani zinthu izi:

Mphamvu zamagetsi ndizofotokozedwa molingana ndi makina ophatikizira butt

Chingwe chamagetsi sichinaswe kapena kuvala

Masamba a chida chokonzekera ndi chakuthwa

Zida zonse ndizabwinobwino

Zigawo zonse zofunika ndi zida zilipo

Makinawa ali m'malo abwino

5.3 Ikani zoyikapo zoyenera molingana ndi kukula kwa chitoliro / kokwanira

5.4 Njira yowotcherera

5.4.1. Musanayambe kuwotcherera, choyamba, fufuzani ngati pali mikwingwirima kapena ming'alu pamwamba pa mipope/zopangira. Ngati kuya kwa mikwingwirima kapena ming'alu kupitilira 10% ya makulidwe a khoma, chotsani zokhwasulazo kapena ming'alu.

5.4.2 Yeretsani mkati ndi kunja kwa chitoliro kuti muwotchedwe.

5.4.3 Ikani mapaipi/zoyikapo ndi kusunga utali wautali wa mapaipi/zowonjezera kuti ziwotcherera zikhale zofanana (zaufupi momwe mungathere). Mapeto ena a chitoliro ayenera kuthandizidwa ndi odzigudubuza kuti achepetse kukangana. Mangani zomangira za zingwe kuti mukonze mapaipi/zolumikizira.

5.4.4 Ikani chida chokonzekera, chiyatseni ndi kutseka mapeto a mapaipi / zopangira pogwiritsa ntchito ndodo ziwiri zoyendetsa galimoto motsutsana ndi chida chokonzekera mpaka kumeta kosalekeza ndi homogenous kuwonekere kumbali zonse ziwiri. Patulani chimango, zimitsani chida chokonzekera ndikuchichotsa. Makulidwe a shavings ayenera kukhala mkati mwa 0.2 ~ 0.5 mm ndipo amatha kusinthidwa posintha kutalika kwa masamba a zida zokonzekera.

6.4.5 Tsekani mapaipi / nsonga zoyenerera ndikuyang'ana momwe zimayendera. Kuyika molakwika sikuyenera kupitirira 10% ya makulidwe a khoma, ndipo kutha kupitilizidwa mwa kumasula kapena kumangitsa zomangira za zingwe. Kusiyana pakati pa malekezero awiri a chitoliro sayenera kupitirira 10% ya makulidwe a khoma; apo ayi mapaipi/zotengera ziyenera kukonzedwanso.

5.4.6 Chotsani fumbi ndikung'amba pa mbale yotenthetsera (Osakanda PTFE wosanjikiza pamwamba pa mbale yotenthetsera).

5.4.7 Ikani mbale yotenthetsera mu chimango itatha kutentha kofunikira. Kwezani kukakamiza mpaka momwe mwatchulira pochita pa chogwiriracho mpaka mkanda ufika kutalika komwe kumafunikira.

5.4.8 Chepetsani kuthamanga kwa mtengo womwe ndi wokwanira kuti mbali zonse ziwiri zigwirizane ndi mbale yotenthetsera kwa nthawi yodziwika.

5.4.9 Nthawi ikatha patulani chimango ndikuchotsa mbale yotenthetsera, phatikizani mbali ziwirizo mwachangu momwe mungathere.

5.4.10 Wonjezerani kukakamiza mpaka mkanda wofunikira uwonekere. Mangani chokhocho kuti cholumikizira chizizizira chokha. Pomaliza tsegulani zikhomo ndikutulutsa chitoliro cholumikizira.

5.4.11 Yang'anani mwachiwonekere cholumikizira. Mgwirizano uyenera kukhala wosalala symmetry, ndipo pansi pa poyambira pakati pa mikanda sayenera kutsika kuposa chitoliro pamwamba. Kusokonekera kwa mikanda iwiri sikuyenera kupitirira 10% ya makulidwe a khoma, kapena kuwotcherera kumakhala koyipa.

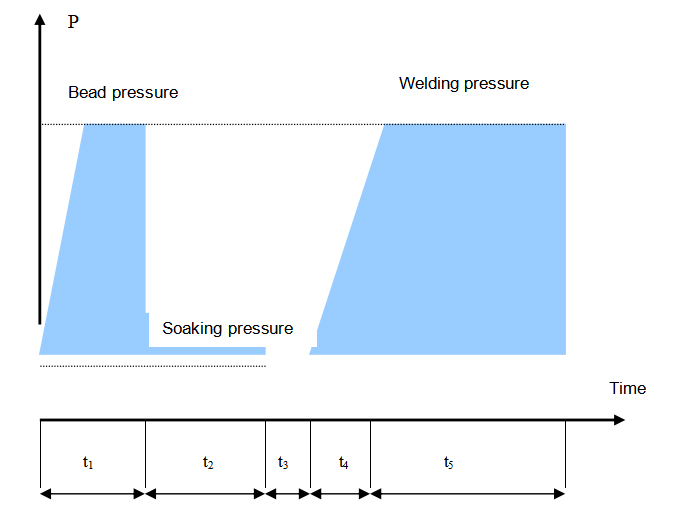

Reference Welding Standard (DVS2207-1-1995)

6.1 Chifukwa cha kusiyana kwa kuwotcherera muyezo ndi zinthu za PE, nthawi ndi kupanikizika zimasiyana m'magawo osiyanasiyana a kuwotcherera. Zikusonyeza kuti magawo enieni kuwotcherera ayenera kuperekedwa ndi mapaipi ndi zovekera 'wopanga.

| Khoma makulidwe (mm) | Kutalika kwa mikanda (mm) | Kuthamanga kwa mikanda (MPa) | Kutaya nthawi t2(mphindikati) | Kuthamanga kwamadzi (MPa) | Kusintha - pakapita nthawi t3(mphindikati) | Pressure build-nthawi t4(mphindikati) | Welding pressure (MPa) | Nthawi yozizira t5(mphindi) |

| 0 ~ 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5 ~ 7 | 1.0 | 0.15 | 45; 70 | ≤0.02 | 5; 6 | 5; 6 | 0.15±0.01 | 6; 10 |

| 7; 12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6; 8 | 6; 8 | 0.15±0.01 | 10; 16 |

| 12; 19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8; 10 | 8; 11 | 0.15±0.01 | 16; 24 |

| 19; 26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10; 12 | 11; 14 | 0.15±0.01 | 24; 32 |

| 26; 37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12; 16 | 14; 19 | 0.15±0.01 | 32; 45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16-20 | 19; 25 | 0.15±0.01 | 45-60 |

| 50-70 | 4.0 | 0.15 | 500-700 | ≤0.02 | 20-25 | 25; 35 | 0.15±0.01 | 60-80 |

Zindikirani: Kuthamanga kwa mikanda yomanga ndi kuwotcherera mu mawonekedwe ndiko kukakamizidwa kwa mawonekedwe, kuthamanga kwa gauge kuyenera kuwerengedwa motere.

Mawu:

Kuwotcherera kuthamanga(Mpa)=(Gawo la kuwotcherera chitoliro ×0.15N/mm2)/(2 ×8×8×3.14) + Kokani kuthamanga

Pano,1 mpa=1N/mm2