TPW200 BUTT FUSION MACHINE Aiki MAN

Matsakaicin Range da Sigar Fasaha

| Nau'in | Saukewa: TPWS200 |

| Kayayyaki | PE, PP da PVDF |

| Kewayon diamita × kauri | 200mm × 11.76mm |

| Yanayin yanayi. | -5 ℃ |

| Tushen wutan lantarki | 220V± 10%, 60Hz |

| Jimlar halin yanzu | 12 A |

| Jimlar iko | 2.0 KW |

| Hada da: farantin dumama | 1.2 KW |

| Kayan aikin tsarawa | 0.8 KW |

| Max. Zazzabi | <270 ℃ |

| Bambanci a cikin yanayin zafin jiki na farantin dumama | ± 5 ℃ |

| Max. matsin lamba | 1040N |

| Jimlar nauyi (kg) | 35KG |

Gabatarwar Injin

Injin ya ƙunshi firam na asali, farantin dumama, kayan aiki da tallafi.

Umarni Don Amfani

5.1 Ya kamata a sanya dukkan kayan aiki a kan tsayayyiyar jirgin sama mai bushe don aiki.

5.2 Kafin aiki tabbatar da abubuwa masu zuwa:

Wutar wutar lantarki shine ƙayyadaddun bisa ga injin haɗakar butt

Layin wutar lantarki ba ya karye ko sawa

Gilashin kayan aikin tsarawa suna da kaifi

Duk kayan aikin al'ada ne

Duk sassan da ake buƙata da kayan aikin suna samuwa

Injin yana cikin yanayi mai kyau

5.3 Sanya abubuwan da suka dace daidai da diamita na waje na bututu / dacewa

5.4 Hanyar walda

5.4.1. Kafin walda, da farko, bincika idan akwai karce ko fissures a saman bututu / kayan aiki. Idan zurfin karce ko fissures ya wuce 10% na kauri na bango, cire karce ko fissures.

5.4.2 Tsaftace ciki da waje na ƙarshen bututu don waldawa.

5.4.3 Sanya bututu / kayan aiki da kuma kiyaye tsayin tsayin bututu / kayan aiki da za a yi waldi daidai (a takaice kamar yadda zai yiwu). Wani ƙarshen bututu ya kamata a goyan bayan rollers don rage gogayya. A ɗaure skru na ƙugiya don gyara bututu / kayan aiki.

5.4.4 Sanya kayan aikin tsarawa, kunna shi kuma rufe ƙarshen bututu / kayan aiki ta hanyar amfani da sandunan direba biyu a kan kayan aikin tsarawa har sai an ci gaba da aske iri ɗaya daga bangarorin biyu. Ware firam ɗin, kashe kayan aikin tsarawa kuma cire shi. Girman shavings ya kamata ya kasance a cikin 0.2 ~ 0.5 mm kuma ana iya daidaita shi ta hanyar daidaita tsayin kayan aikin kayan aiki.

6.4.5 Rufe bututu / ƙare masu dacewa kuma duba daidaitawa. Matsala bai kamata ya wuce kashi 10% na kauri na bango ba, kuma ana iya inganta shi ta hanyar sassautawa ko ƙara ƙarar ƙullun. Rata tsakanin iyakar bututu guda biyu kada ta wuce 10% na kauri na bango; in ba haka ba ya kamata a sake shirya bututu / kayan aiki.

5.4.6 Share ƙura da tsaga a kan dumama farantin (Kada a karce Layer PTFE a saman dumama farantin).

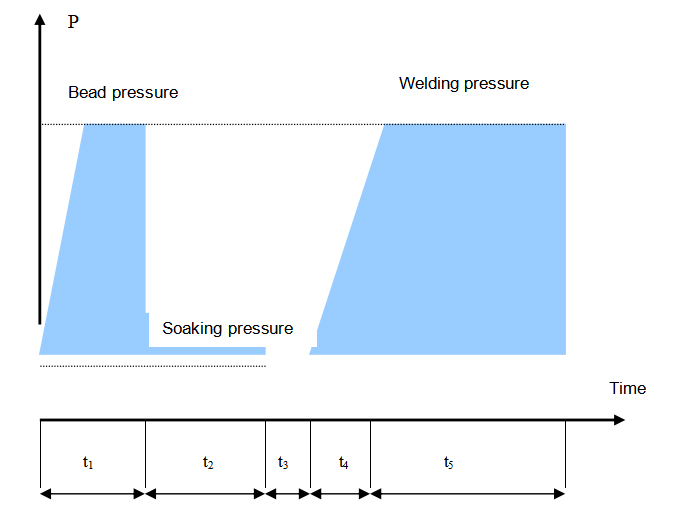

5.4.7 Saka farantin dumama cikin firam bayan ya sami zafin da ake buƙata. Ɗaga matsi har zuwa ƙayyadaddun ta hanyar yin aiki a kan riƙon har sai dutsen ya kai tsayin da ake buƙata.

5.4.8 Rage matsa lamba zuwa ƙima wanda ya isa don kiyaye bangarorin biyu suna taɓa farantin dumama don ƙayyadadden lokaci.

5.4.9 Lokacin da lokaci ya wuce raba firam ɗin kuma cire farantin dumama, haɗa bangarorin biyu da sauri.

5.4.10 Ƙara matsa lamba har sai da dutsen da ake buƙata ya bayyana. Daure na'urar kulle don kiyaye haɗin gwiwa ya yi sanyi da kanta. A ƙarshe buɗe ƙugiya kuma fitar da bututun da aka haɗa.

5.4.11 Duba haɗin gwiwa da gani. Haɗin gwiwa ya kamata ya zama santsi mai santsi, kuma kasan tsagi tsakanin beads kada ya zama ƙasa da saman bututu. Ƙaƙƙarfan ƙaƙƙarfan beads guda biyu kada ya wuce 10% na kauri na bango, ko waldawar ba ta da kyau.

Matsayin Welding Reference (DVS2207-1-1995)

6.1 Saboda bambance-bambance a cikin daidaitattun walda da kayan PE, lokaci da matsa lamba sun bambanta a matakai daban-daban na walda. Yana ba da shawarar cewa ya kamata a ba da ainihin sigogin walda ta hanyar bututu da masana'anta.

| Kaurin bango (mm) da | Tsayin bead (mm) | Ƙunƙarar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara (MPa) | Lokacin jiƙa t2( dakika) | matsa lamba (MPa) | Canje-canje a lokaci guda t3( dakika) | Lokacin gina matsi t4( dakika) | Welding matsa lamba (MPa) | Lokacin sanyi t5(min) |

| 0 zuwa 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15 ± 0.01 | 6 |

| 4.5 zuwa 7 | 1.0 | 0.15 | 45 zuwa 70 | ≤0.02 | 5 zuwa 6 | 5 zuwa 6 | 0.15 ± 0.01 | 6 zuwa 10 |

| 7 zuwa 12 | 1.5 | 0.15 | 70 ~ 120 | ≤0.02 | 6 zuwa 8 | 6 zuwa 8 | 0.15 ± 0.01 | 10 zuwa 16 |

| 12 zuwa 19 | 2.0 | 0.15 | 120 ~ 190 | ≤0.02 | 8 zuwa 10 | 8 zuwa 11 | 0.15 ± 0.01 | 16 zuwa 24 |

| 19 zuwa 26 | 2.5 | 0.15 | 190 zuwa 260 | ≤0.02 | 10 zuwa 12 | 11 zuwa 14 | 0.15 ± 0.01 | 24 zuwa 32 |

| 26 zuwa 37 | 3.0 | 0.15 | 260 ~ 370 | ≤0.02 | 12 zuwa 16 | 14 zuwa 19 | 0.15 ± 0.01 | 32 zuwa 45 |

| 37 zuwa 50 | 3.5 | 0.15 | 370 ~ 500 | ≤0.02 | 16 zuwa 20 | 19 zuwa 25 | 0.15 ± 0.01 | 45 zuwa 60 |

| 50 ~ 70 | 4.0 | 0.15 | 500 ~ 700 | ≤0.02 | 20 zuwa 25 | 25 zuwa 35 | 0.15 ± 0.01 | 60 zuwa 80 |

Lura: Matsi na ginawa na bead da matsin walda a cikin nau'i shine matsin lamba da aka ba da shawarar, yakamata a lissafta ma'aunin ma'auni tare da dabara mai zuwa.

Magana:

Matsin walda(Mpa)=(Sashin bututun walda ×0.15N/mm2)/(2 ×8×8×3.14) + Jawo matsa lamba

nan, 1Mpa= 1 N/mm2